Construction waste crushing device for construction

A construction waste and pulverizing device technology, which is applied in combination devices, separation methods, and dispersed particle separation, etc., can solve problems such as personal injury, low pulverization, and dust explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

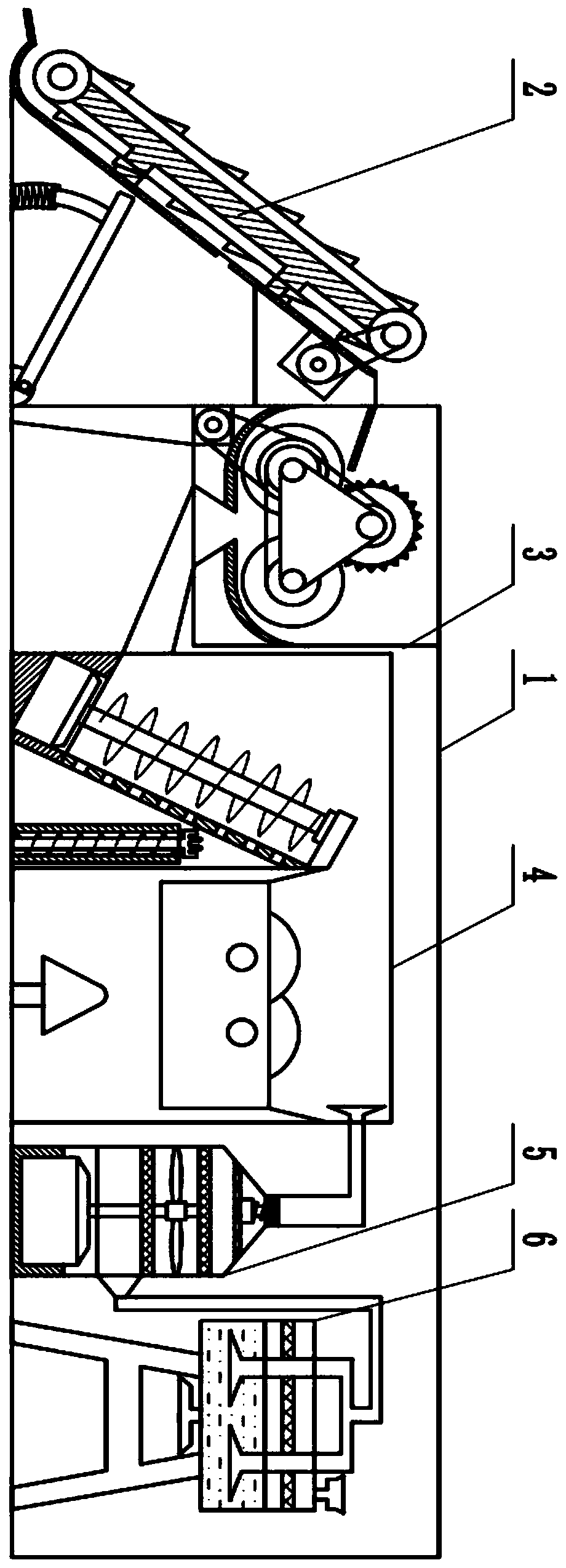

[0032] Combine below figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 illustrate this embodiment, the technical problem that the present invention mainly solves is to provide a kind of construction waste crushing device for construction, comprising box body 1, conveyor belt base 2. The crushing box 3, the crushing and sorting box 4, the dust removal box 5, and the filter box 6 can solve the problem that construction waste is usually transported by large trucks to the open space for centralized stacking or reclamation. This method causes a great waste of resources problems, and the existing construction waste crushing device has a simple structure and low crushing degree, and a large amount of dust and dust will be generated during the crushing process, which is prone to dust explosion and human body damage.

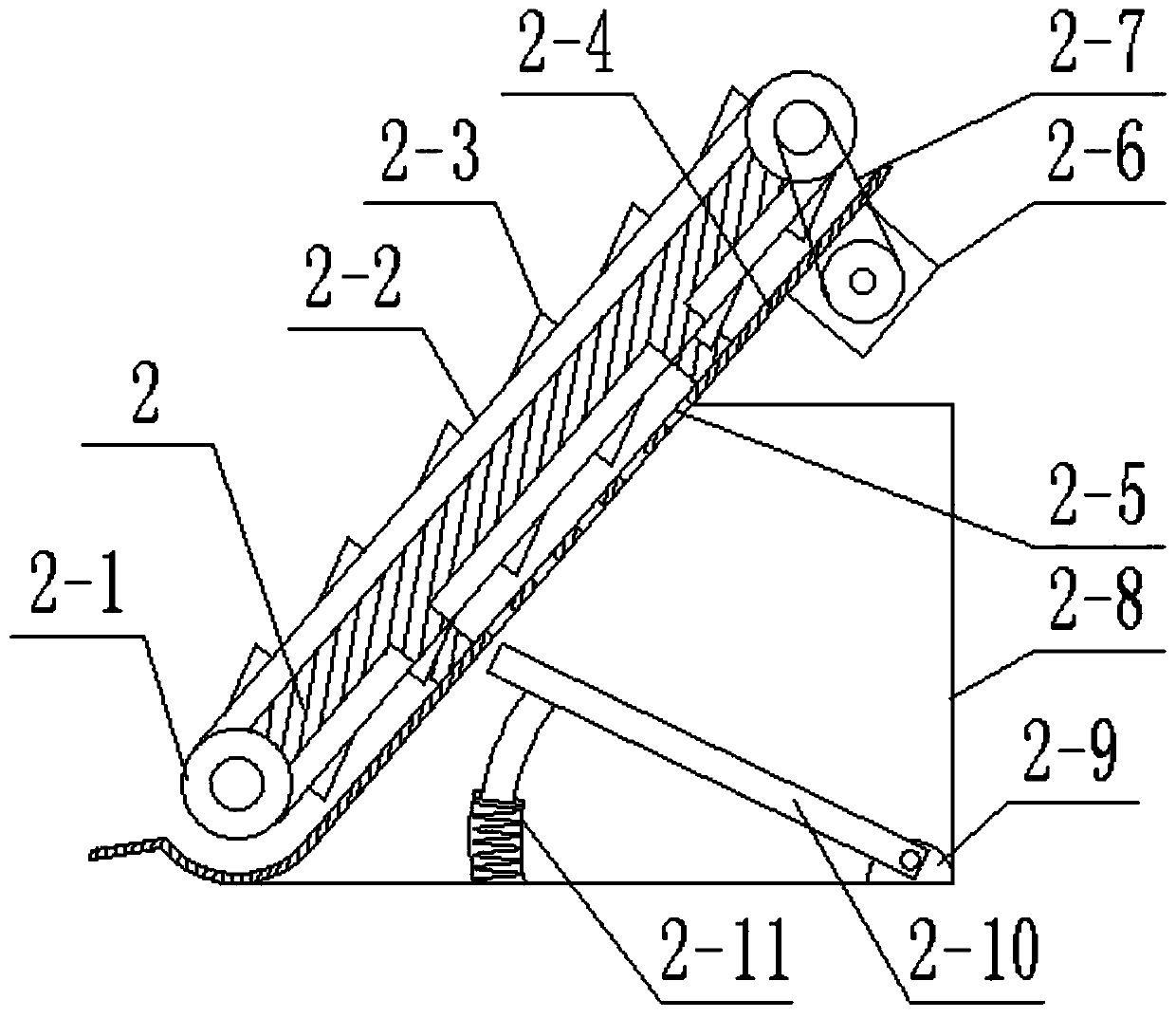

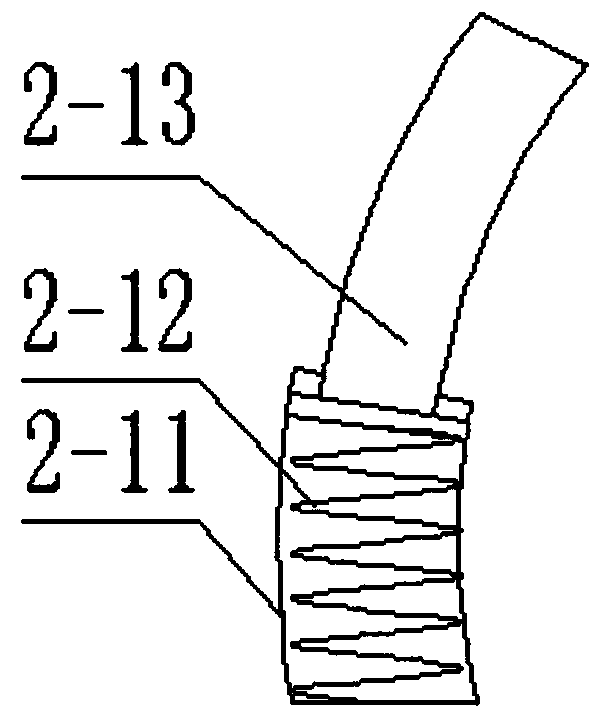

[0033] Conveyor belt base 2 is provided with conveying roller 2-1, conveying belt 2-2, triangular limit block 2-3, conveying retaining plate 2-4, conveying retaining plate hole...

specific Embodiment approach 2

[0040] Combine below figure 1 , 2 . Rotating shaft 4-14, transmission gear 4-15 are all set to two.

specific Embodiment approach 3

[0042] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11 illustrate this embodiment, and this embodiment will further explain Embodiment 1, the transport box motor base 4-3, the transport box motor 4- 4. The rotating shaft 4-5 of the transport box and the spiral fan blade 4-6 share the central line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com