Micro-strip energy collector and broadband fluid energy collector

An energy harvester, microstrip technology, applied in electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve the problem of narrow working bandwidth, low output voltage/power, difficult Meet the requirements of energy storage and driving devices, and achieve the effect of increasing the flow rate and reducing the difficulty of collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution and provides detailed implementation and specific operation process, but the scope of the present invention is not limited to this embodiment. example.

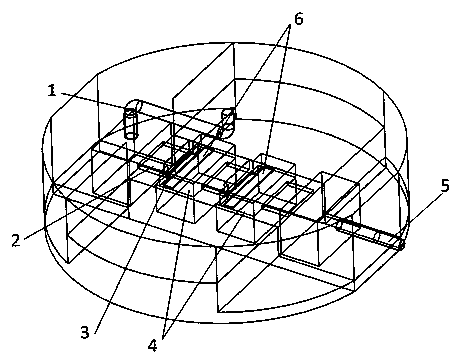

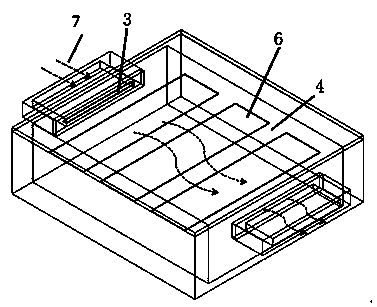

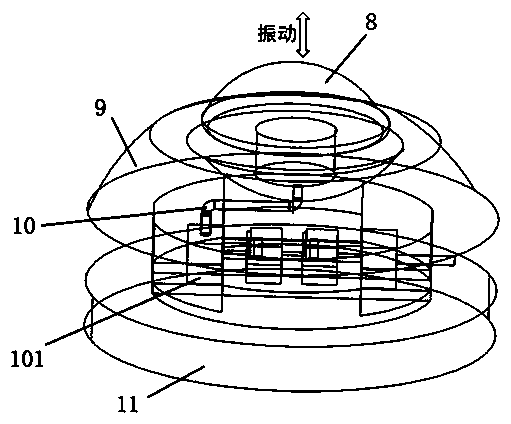

[0018] like Figure 1-2 As shown, a microstrip energy harvester includes a fluid inlet 1, a nozzle 2, a bluff body 3, a microcavity 4, a microstrip 6 and a fluid outlet 5; the fluid inlet 1 is connected to the outside and the nozzle 2 respectively The outlet of the nozzle 2 is connected to the microcavity 4; the bluff body 3 is located at the position corresponding to the outlet of the nozzle 2 inside the microcavity 4 (that is, the bluff body 3 is located in the microcavity 4 At the entrance of the), when the fluid 7 enters the microcavity 4 through the nozzle 2 and interacts with the bluff body 3, the bluff body 3 flutters; One side of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com