Electric heating cold salt tank

An electric heating and electric heater technology, applied in the field of mechanical devices, can solve the problems affecting the stability of the power generation system, the inability to ensure the temperature balance of the molten salt tank, and the molten salt, so as to achieve work stability, ensure the temperature of the molten salt, Uniform effect of heat transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

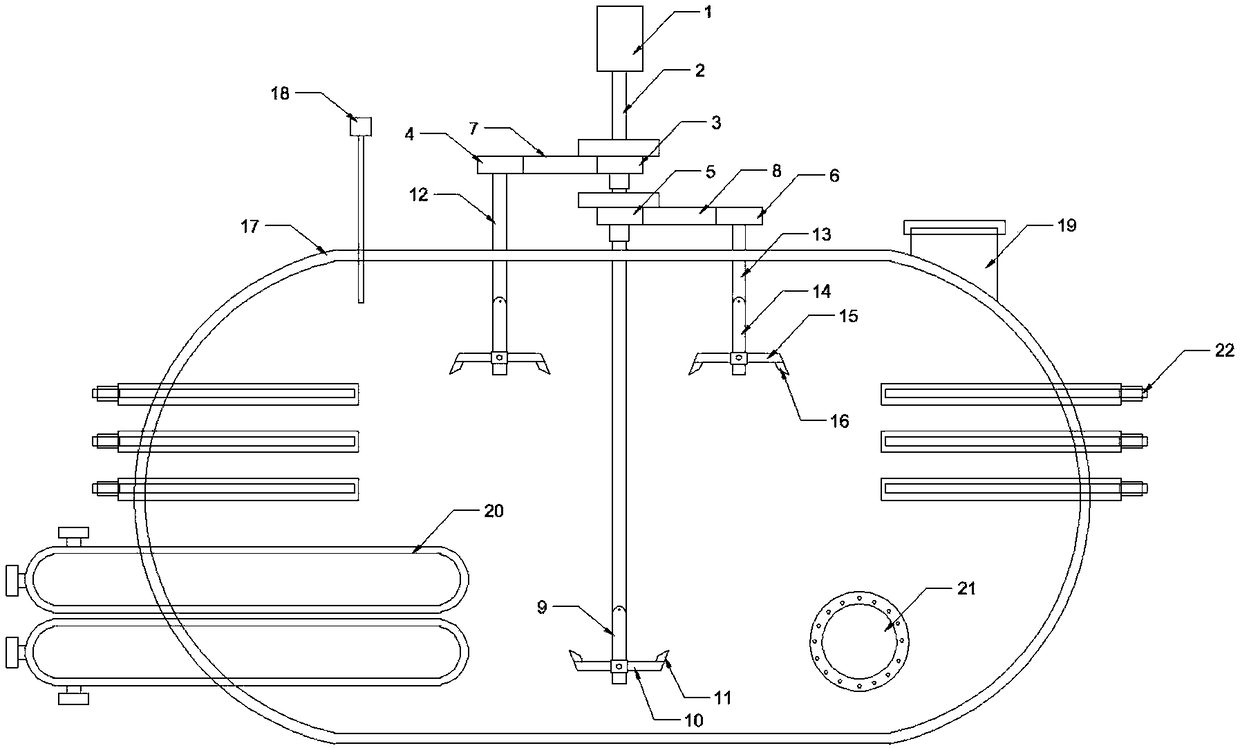

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] As shown in the figure, an electric heating cold salt tank includes a tank body, an electric heater, a U-shaped heat exchange pipe and a stirring device. The upper end of the tank body is provided with a molten salt inlet, and the bottom of the tank body is provided with a manual maintenance inlet. ;

[0024] Among them, the electric heater is an explosion-proof electric heater, and the explosion-proof electric heater is arranged along the vertical row, symmetrically arranged on both sides of the tank body;

[0025] Among them, the U-shaped heat exchange pipe is arranged under the electric heater at the bottom of the electric heater, the number of the U-shaped heat exchange pipes is 2-5 groups, and the heat exchange medium in the U-shaped heat exchange pipe is water. The heat exchange pipe is also provided with a water inlet and a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com