Processing method of biogas residue liquid

A processing method and biogas residue technology, applied in chemical instruments and methods, water treatment parameter control, special treatment targets, etc., can solve the problems of waste, small treatment capacity, low dehydration rate, etc., to improve the excitation effect and purification Ability, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

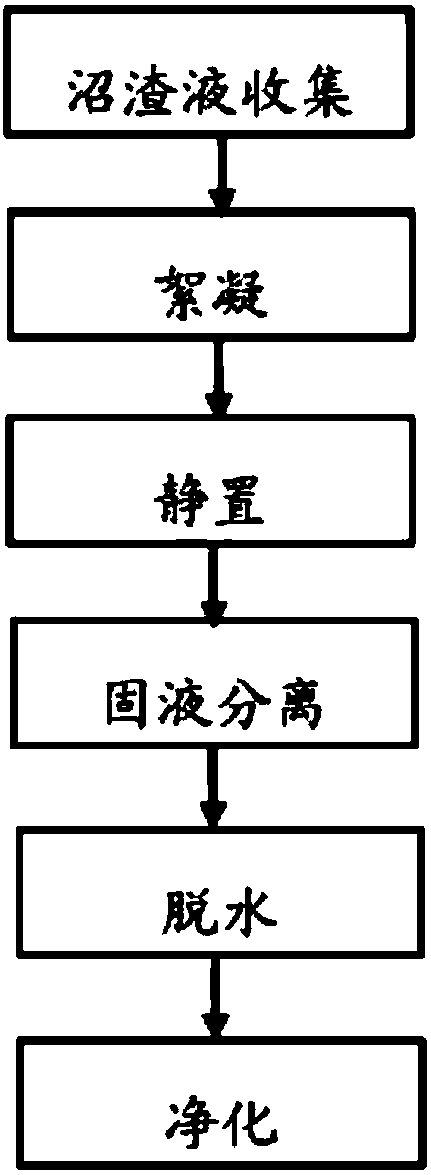

[0036] Such as figure 1 As shown, the present embodiment provides a processing method of biogas residue liquid, comprising the following steps:

[0037] Step 1, biogas residue liquid collection;

[0038] Step 2, flocculation;

[0039] Step 3, stand still;

[0040] Step 4, solid-liquid separation;

[0041] Step 5, dehydration;

[0042] Step 6, purification treatment.

[0043] in:

[0044] In step 1, the collected biogas residue comes from the anaerobic fermentation product of poultry manure, which is a turbid solid-liquid mixture.

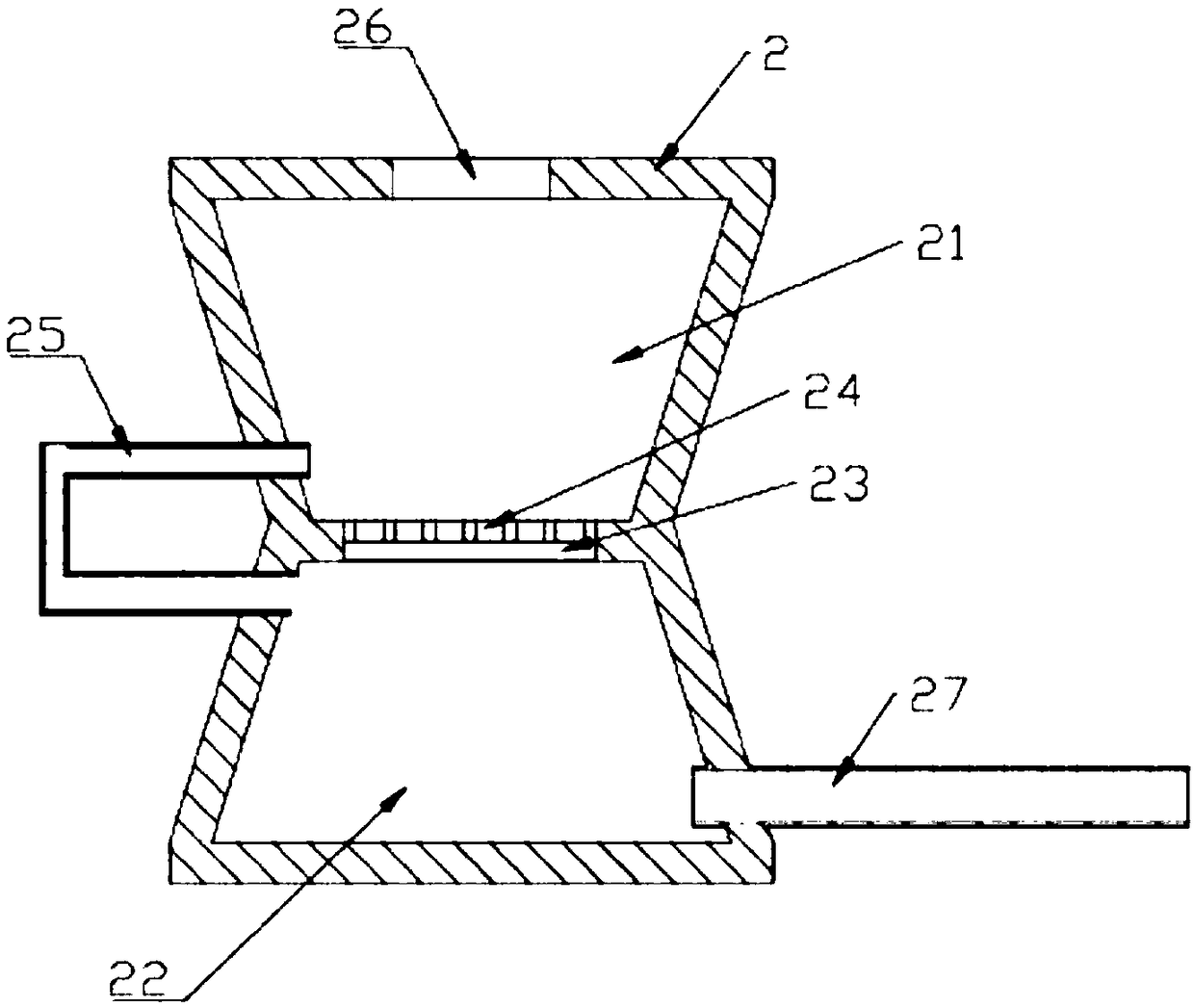

[0045] In step 2, the expansion is mainly carried out in a settling tank, and heating and stirring devices are arranged in the settling tank. During specific implementation, flocculants and magnetic particles are added to the biogas residue liquid in the settling tank, and the addition ratio is 2 g of flocculants and 0.5 g of magnetic particles to 1L of biogas residue liquid. In order to improve the flocculation effect of flocculants and mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com