Lining polymer composite silicon carbide ceramic impeller mold

A composite silicon carbide and polymer technology, used in ceramic molding machines, mold fixtures, mold auxiliary parts, etc., can solve problems such as position deviation, mold positioning is not very good, affecting the use effect of molds, etc., to achieve convenient and stable use. , The effect of positioning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

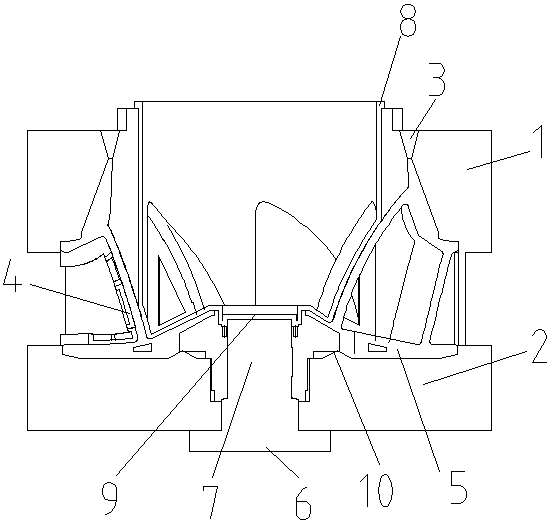

[0012] A polymer-lined composite silicon carbide ceramic impeller mold is provided with an upper mold 1 and a lower mold 2, the upper mold 1 is arranged on the upper part of the lower mold 2, and a pouring port 3 is arranged on the top of the upper mold 1 , a core mold 8 is provided on the side of the upper mold 1, a blade mold 4 is provided at the lower end of the core mold 8, a skeleton 5 is arranged between the upper mold 1 and the lower mold 2, and the lower mold 2 A positioning component 6 is provided at the central position.

[0013] The positioning component 6 is a positioning block, and the positioning block is embedded in the lower mold 2 .

[0014] The positioning block is provided with a connecting platform 7, and the connecting platform 7 is arranged on the top of the positioning block.

[0015] The pouring port 3 is obliquely inserted into the upper mold 1 .

Embodiment 2

[0017] A polymer-lined composite silicon carbide ceramic impeller mold is provided with an upper mold 1 and a lower mold 2, the upper mold 1 is arranged on the upper part of the lower mold 2, and a pouring port 3 is arranged on the top of the upper mold 1 , a core mold 8 is provided on the side of the upper mold 1, a blade mold 4 is provided at the lower end of the core mold 8, a skeleton 5 is arranged between the upper mold 1 and the lower mold 2, and the lower mold 2 A positioning component 6 is provided at the central position.

[0018] The positioning component 6 is a positioning block, and the positioning block is embedded in the lower mold 2 .

[0019] The positioning block is provided with a connecting platform 7, and the connecting platform 7 is arranged on the top of the positioning block.

[0020] The pouring port 3 is obliquely inserted into the upper mold 1 .

[0021] The mandrel 8 is provided with an engaging groove 9, and the engaging groove 9 engages the posit...

Embodiment 3

[0023] A polymer-lined composite silicon carbide ceramic impeller mold is provided with an upper mold 1 and a lower mold 2, the upper mold 1 is arranged on the upper part of the lower mold 2, and a pouring port 3 is arranged on the top of the upper mold 1 , a core mold 8 is provided on the side of the upper mold 1, a blade mold 4 is provided at the lower end of the core mold 8, a skeleton 5 is arranged between the upper mold 1 and the lower mold 2, and the lower mold 2 A positioning component 6 is provided at the central position.

[0024] The positioning component 6 is a positioning block, and the positioning block is embedded in the lower mold 2 .

[0025] The positioning block is provided with a connecting platform 7, and the connecting platform 7 is arranged on the top of the positioning block.

[0026] The pouring port 3 is obliquely inserted into the upper mold 1 .

[0027] The mandrel 8 is provided with an engaging groove 9, and the engaging groove 9 engages the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com