Cooking utensil

A technology for cooking utensils and components, which is applied to steam cooking utensils, the structure of cooking utensils, cooking utensils, etc., can solve problems such as affecting the cooking process, collision friction, damage to driving devices, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

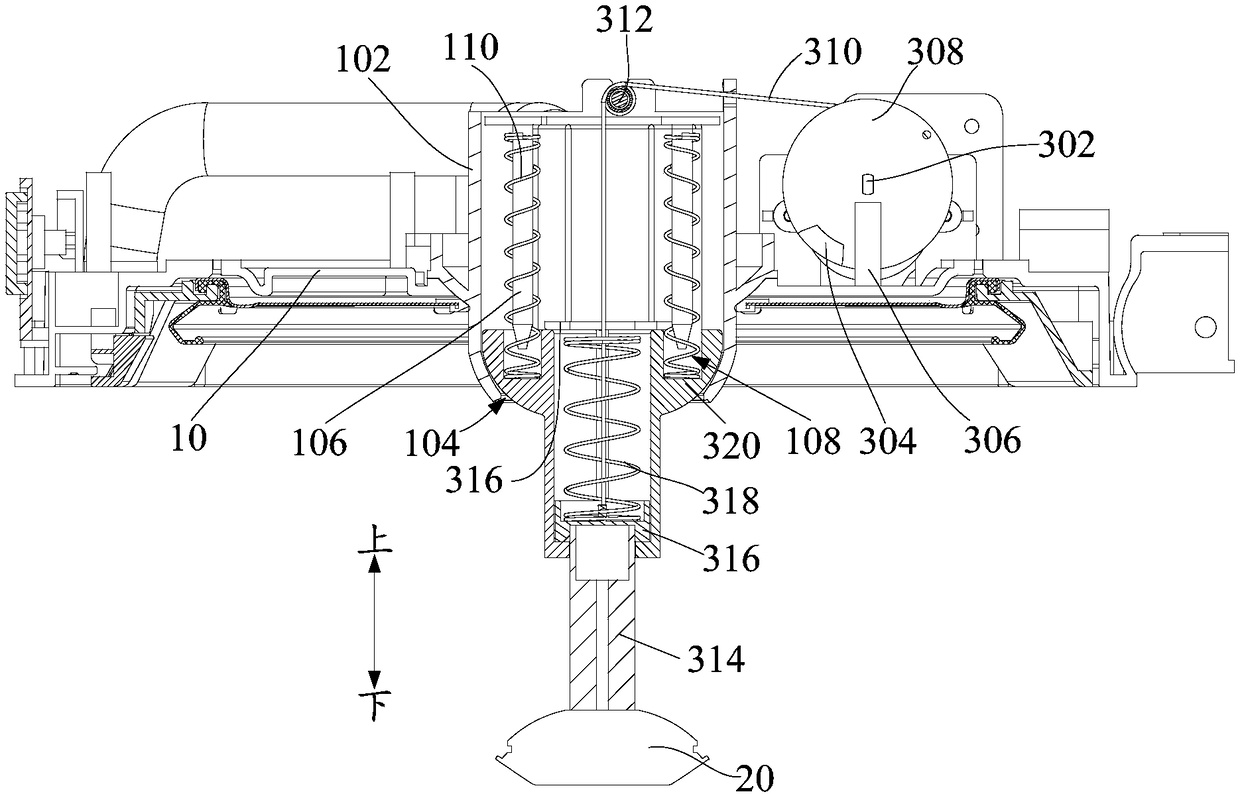

[0068] Embodiment one (as figure 1 and figure 2 shown)

[0069] The stroke control device includes: a first limiter and a second limiter, the first limiter is fixedly connected with the rotating member; the second limiter is fixedly connected with the upper cover 10, and can move to the first position when the cleaning assembly 20 And when it moves to the second position, it interferes with the first limiting member, so as to restrict the rotating member from continuing to rotate, so that the driving device stops running.

[0070] The stroke control device includes a first limiter and a second limiter. The first limiter is fixed on the rotating member and rotates synchronously with the rotating member. The second limiter is fixedly connected with the upper cover 10 and kept relative to the rotating member. Stationary; when the cleaning assembly 20 moves to the first position and to the second position, the second limiting member interferes with the first limiting member (fo...

Embodiment 2

[0081] Embodiment 2 (not shown in the figure)

[0082] The difference from Embodiment 1 is that one of the first limiting member and the second limiting member is an arc-shaped chute, and the other is a protruding post matching the arc-shaped chute, and the protruding post is inserted into the arc-shaped chute and can slide in the arc-shaped chute, wherein, when the cleaning assembly 20 moves to the first position and to the second position, the boss moves to the end of the arc-shaped chute to interfere with the arc-shaped chute .

[0083] This embodiment utilizes the cooperation of the arc-shaped chute and the convex post to make the radian of the arc-shaped chute equal to the rotation angle of the rotating part. The arc chute interferes, which restricts the rotating part from continuing to rotate.

Embodiment 3

[0084] Embodiment three (not shown in the figure)

[0085] The travel control device includes: a trigger and a travel switch, the trigger is arranged on the rotating part; the travel switch is installed on the upper cover 10, and is electrically connected with the electric control board; wherein, when the cleaning assembly 20 moves to the first position and moves to At the second position, the trigger member triggers the travel switch, so that the electric control board controls the driving member to stop running.

[0086] The trigger part is arranged on the rotating part and rotates together with the rotating part; the travel switch is installed on the upper cover 10, remains stationary, and is electrically connected with the electric control board, when the cleaning assembly 20 moves to the first position and moves to the second position , the travel switch is triggered by the trigger, and then generates an electric signal to the electric control board, and the electric cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com