Torsion spring assembly, camshaft phaser and belt or chain tightener therewith

A technology of torsion springs and assemblies, applied in the directions of springs/shock absorbers, belts/chains/gears, springs, etc., can solve undesired problems and achieve the goals of avoiding resonance, improving spring characteristics, long service life and durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

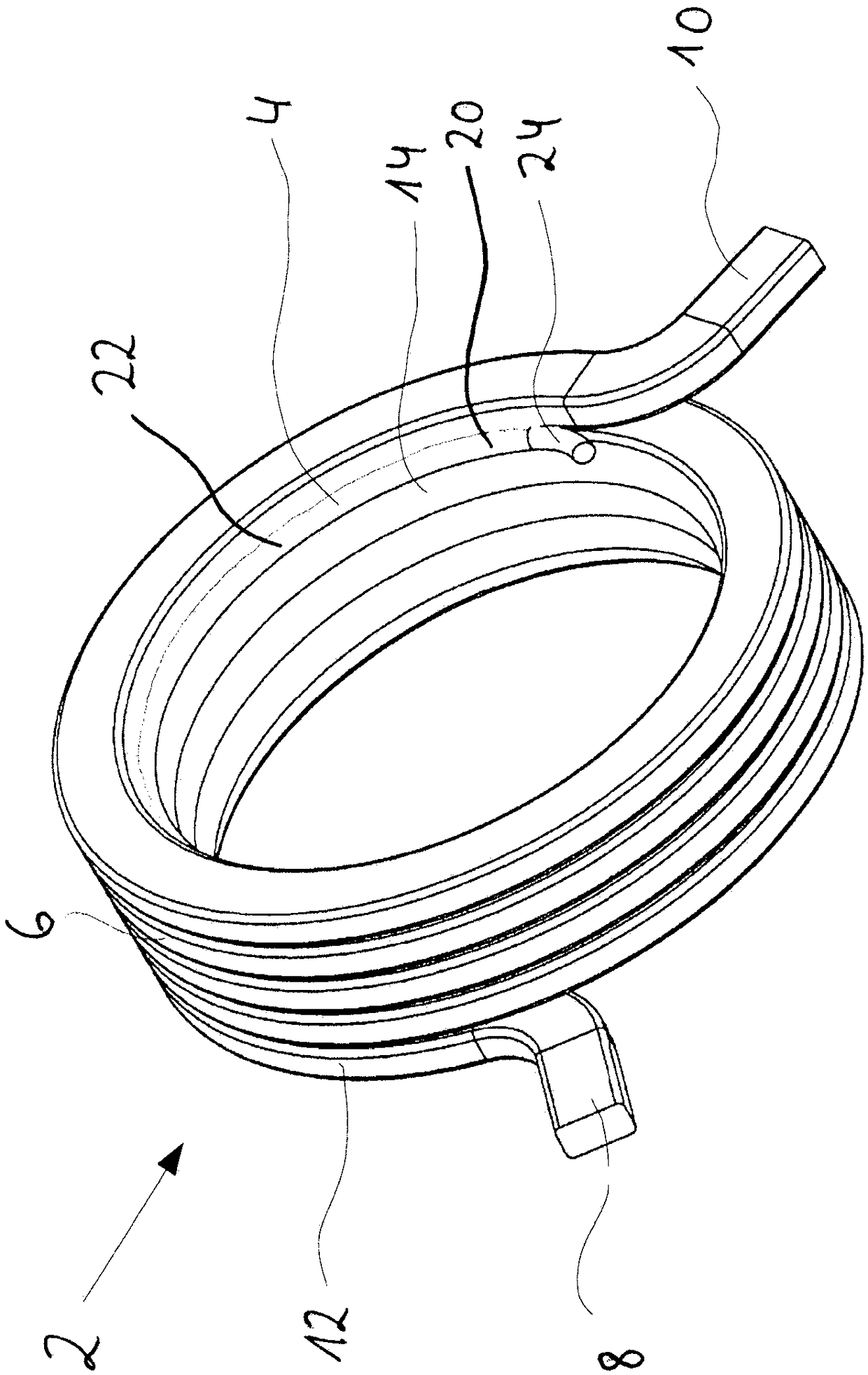

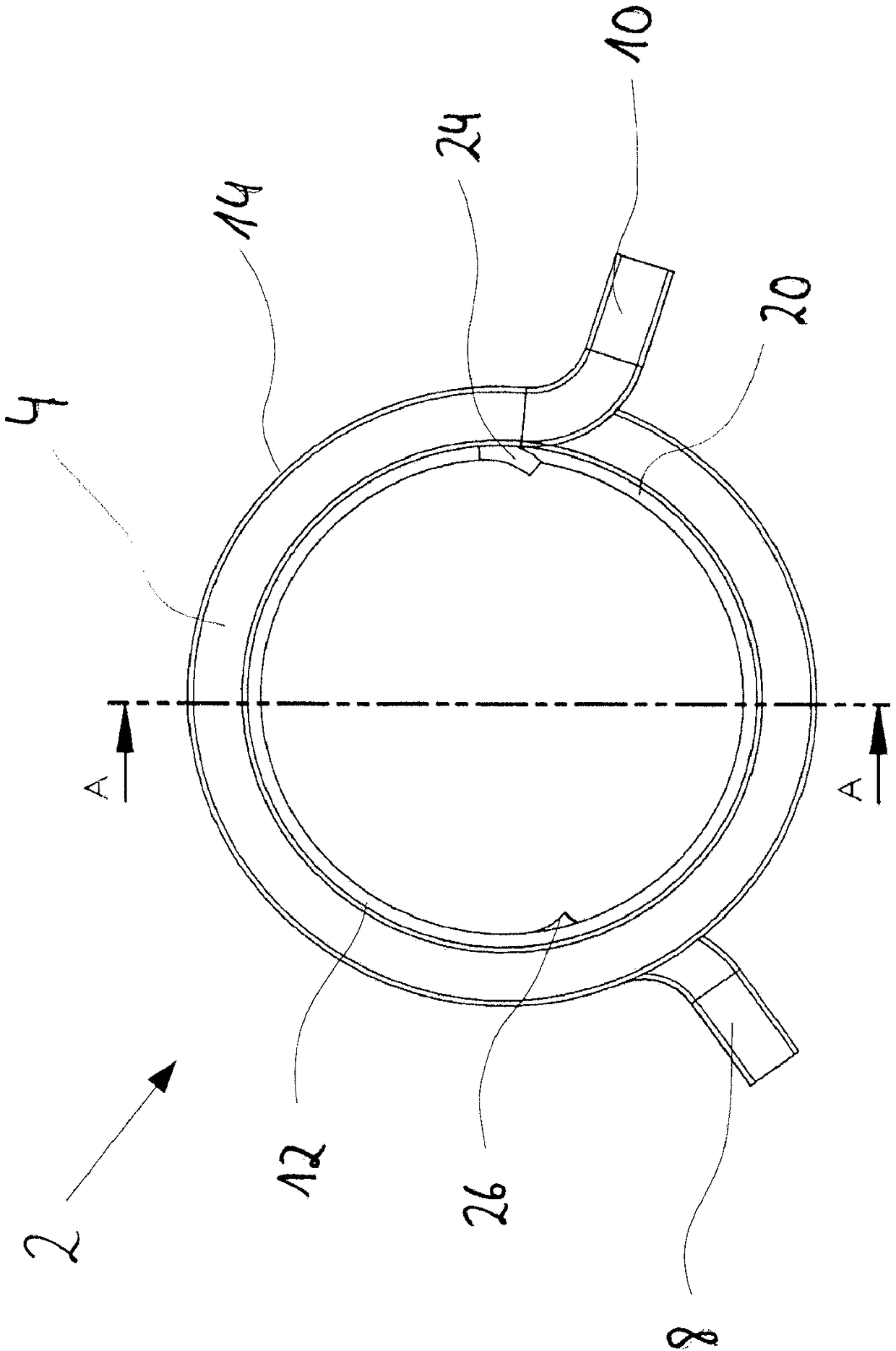

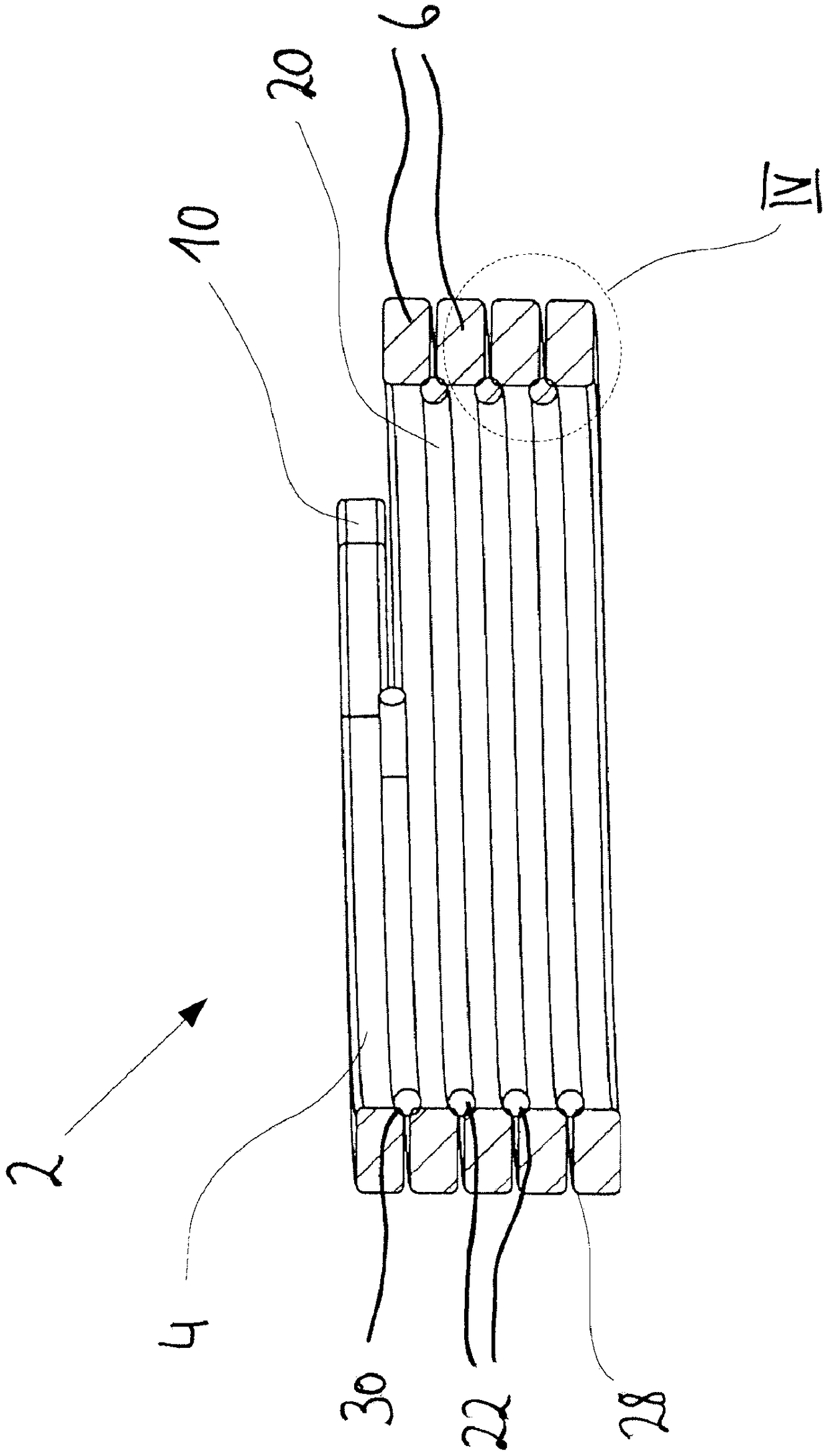

[0057] figure 1 A perspective view of the torsion spring assembly 2 including the torsion spring 4 and the internal damping spring 20 is shown obliquely from above. The torsion spring 4 wound with the spring wire includes a torsion spring winding 6 forming a cylindrical spring body extending around a central axis or a spring axis. The torsion spring 4 includes four torsion spring windings 6 and a first torsion spring wire end 8 and a second torsion spring wire end 10 in an exemplary manner. Of course, the torsion spring 4 may also include more or fewer torsion spring windings 6. The torsion spring 4 is designed to receive the force acting on it through its torsion spring wire ends 8 and 10 in the direction of rotation.

[0058] The torsion spring winding 6 includes a radially inner side 12 having an inner diameter and a radially outer side 14 having an outer diameter, wherein the inner diameter and the outer diameter are different from each other and can be adapted to match spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com