A method for calculating dynamic frequency of self-locking blade of industrial steam turbine

A calculation method and technology for industrial steam turbines, applied in the directions of calculation, computer-aided design, design optimization/simulation, etc., can solve the problems of locking, can not reflect the damping characteristics of contact stiffness, and achieve safe and reliable operation, good economic benefits, and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

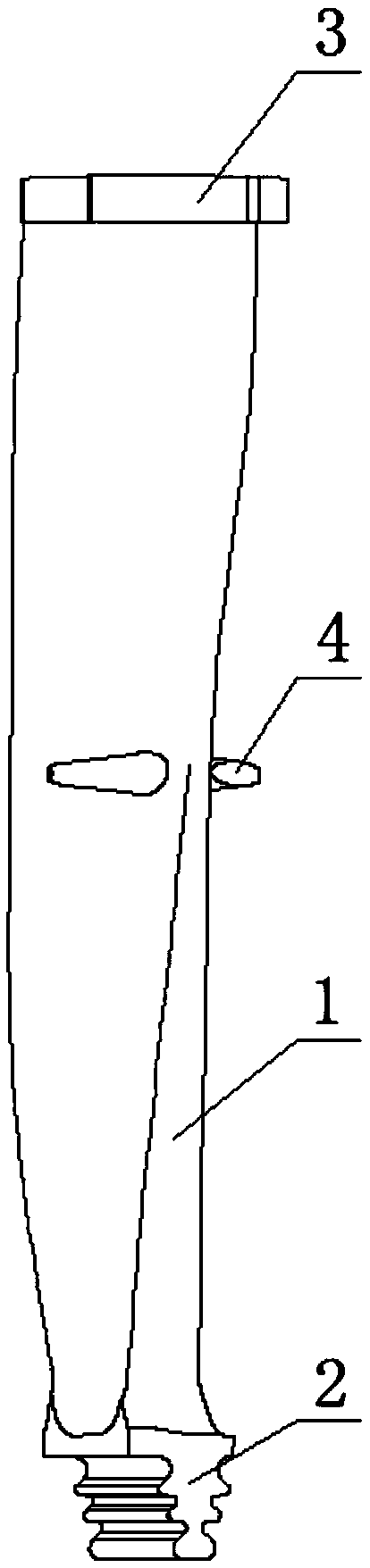

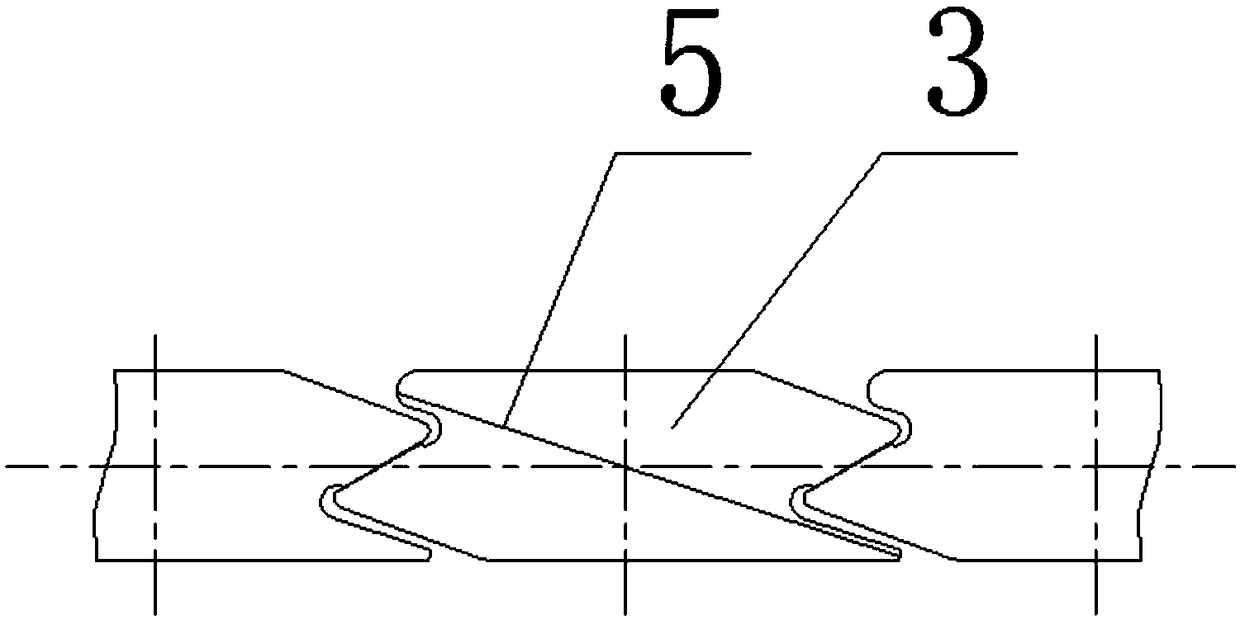

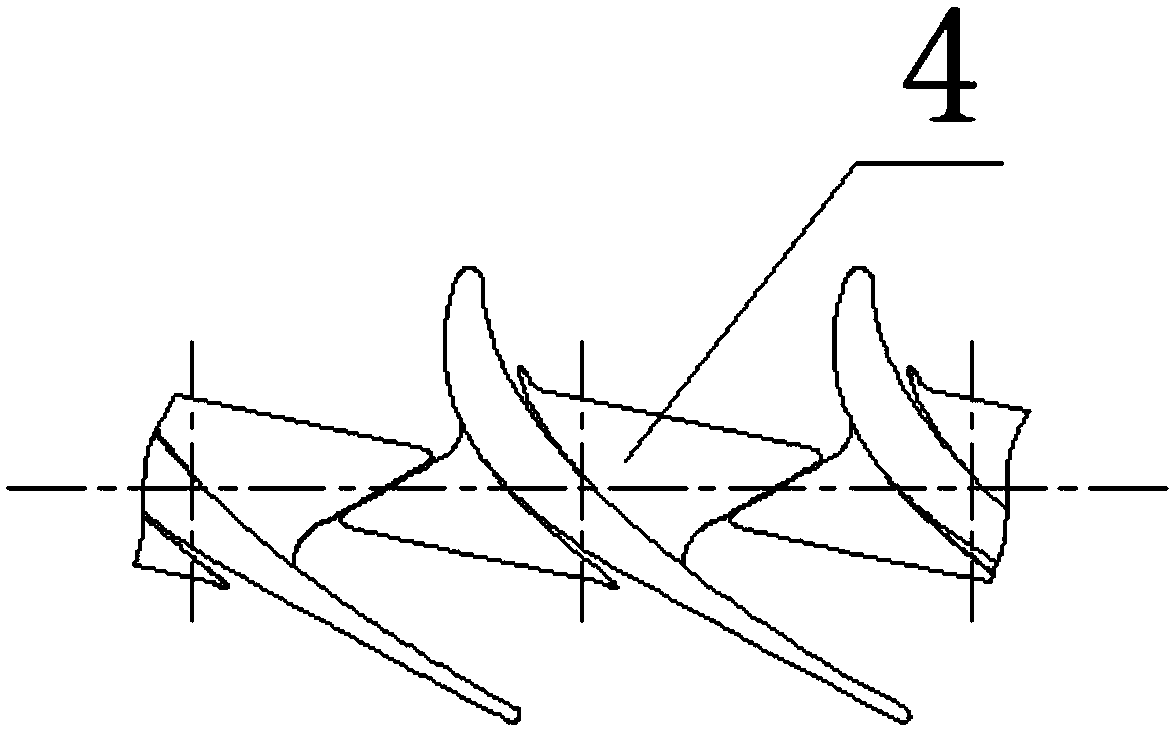

[0019] Such as Figure 1-3 As shown, there is a certain gap between the blade shroud and the boss, and the blade will produce a torsion angle under the action of centrifugal force. , the contact conditions are also different.

[0020] The method for calculating the dynamic frequency of the full-circle self-locking blades of the steam turbine described in this embodiment includes the following steps:

[0021] (1) Calculate the static strength of the blades in contact, and obtain the torsion angle at the top of the blade and the contact pressure between adjacent blade shrouds. The contact pressure is as follows: Figure 5 shown.

[0022] (2) In the area where the contact pressure is greater than 30MPa, that is Figure 5 In the darkest area, the spring unit MATRIX27 is established between the nodes on it, with a total of 48 units, such as Figure 4 shown.

[0023] (3) Let the normal stiffness k of the above spring unit n Same, tangential stiffness k t also the same, let v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com