Sealing ring, sealing method of watchcase assembly and watchcase assembly

A shell assembly and sealing ring technology, which is applied to clocks, casings, mechanically driven clocks, etc., can solve the problems of deformation of the installation groove, difficulty in installing the sealing ring, and extrusion damage of the sealing ring, etc., to achieve excellent sealing performance, The effect of low cost and simple sealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

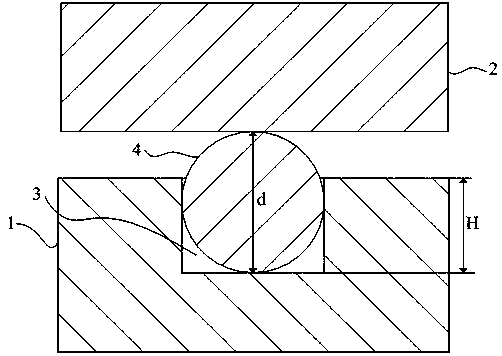

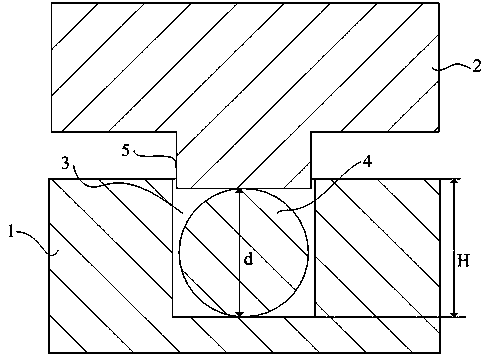

[0038] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

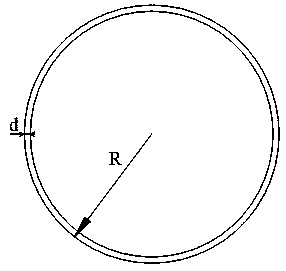

[0039] refer to Figure 4 to Figure 7 , a sealing ring 100 in this embodiment, including a sealing portion 110, an adhesive and tearable upper attachment film 120 and a lower attachment film 130, the sealing portion 110 is located on the upper attachment film 120 and the lower attachment film 130 between, and with the upper attachment film 120 and the lower attachment film 130 through the adhesive bonding of the upper attachment film 120 and the lower attachment film 130; the sealing part 110 includes a concentric sealing ring body 111, with The viscous inner elastic rubber ring 112 and the outer elastic rubber ring 113, the sealing ring body 111 is located between the inner elastic rubber ring 112 and the outer elastic rubber ring 113, and the sealing ring body 111 and the inner elastic rubber ring 112 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com