Anti-vibration optical module and anti-vibration method

A technology of optical components and lens components, which is applied in the direction of optical components, optics, and light guides, can solve the problems of shortening the distance between the light emitting device and the photodetection device, reducing the distance between the light emitting device and the filtering device, and the substrate is susceptible to external interference, etc., to achieve Improve practicability, improve firmness, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

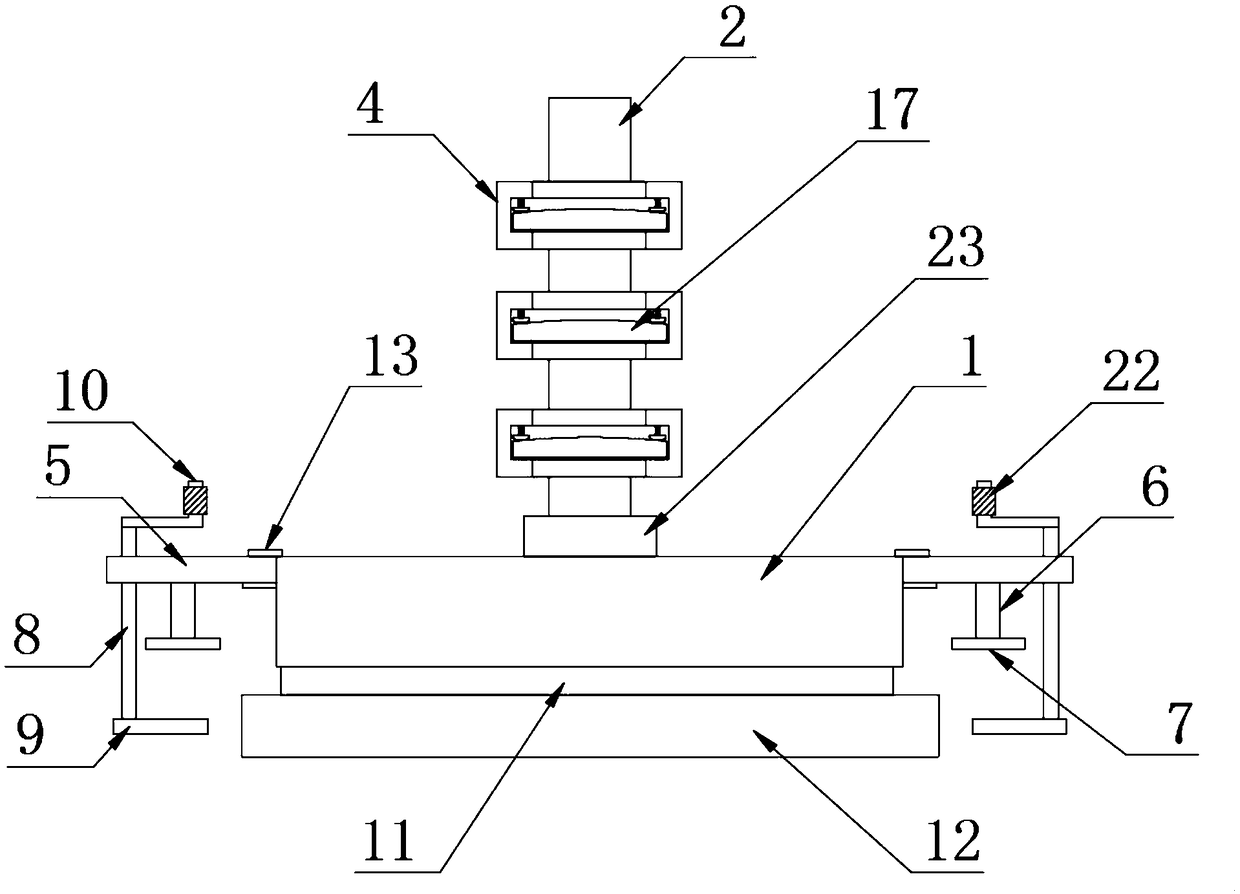

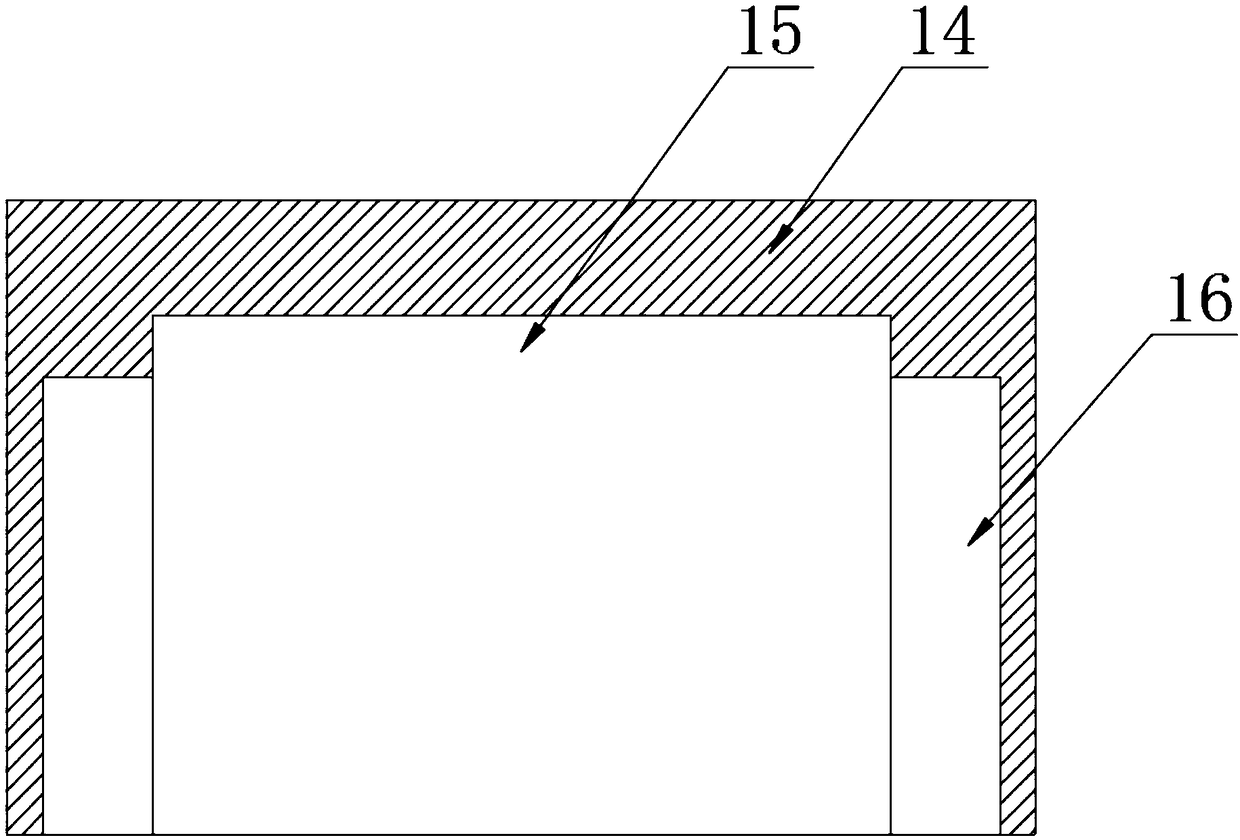

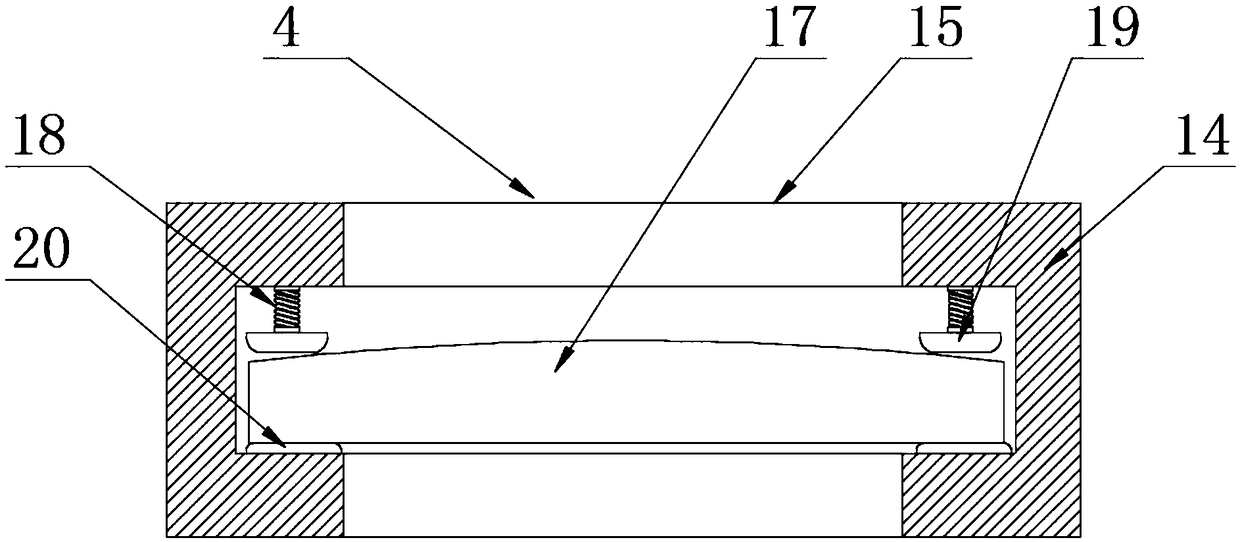

[0028] The present invention provides such Figure 1-4 The anti-shock optical assembly shown includes a base 1, a fixed rod 2 is arranged on the top of the base 1, and a plurality of fixed rings 3 are sleeved on the outside of the fixed rod 2, and a lens assembly 4 is arranged on one side of the fixed ring 3 Both sides of the base 1 are movably connected with adjustment rods 5 through hinges, the bottom of the middle part of the adjustment rod 5 is provided with a first support rod 6, and the bottom of the first support rod 6 is provided with a first splint 7. One end of the adjusting rod 5 away from the base 1 is provided with a moving rod 8, the bottom of the moving rod 8 is provided with a second splint 9, the top of the moving rod 8 is provided with a rotating rod 10, and the bottom of the base 1 is provided with a buffer pad 11, The bottom of the buffer pad 11 is provided with a base plate 12 , and the top and bottom of the connection between the base 1 and the adjusting ...

Embodiment 2

[0038] An anti-shock method for an anti-shock optical component, including the anti-shock optical component, also includes the following steps:

[0039] S1: Turn the adjustment lever 5;

[0040] S2: finally turn the rotating rod 10 to make the moving rod 8 move up and down at one end of the adjusting rod 5, so that the second splint 9 moves up and down;

[0041] S3: the top and the bottom of the connection between the base 1 and the adjusting rod 5 are provided with reinforcing plates 13, and the adjusting rod 5 can be flexibly connected to the base 1 through a hinge;

[0042] S4: the adjustment rod 5 is rotated left and right to expand the range in which the first splint 7 and the second splint 9 cooperate with each other;

[0043] S5: the buffer pad 11 is set, and a buffer zone is set between the base 1 and the substrate 12;

[0044] S3: Through the first splint 7 and the second splint 9 that cooperate with each other, the first splint 7 and the second splint 9 clamp the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com