Primer with structure safety and assembling process thereof

A technology for safe detonation and assembly process, applied in blasting, blasting cylinders, weapon accessories, etc., can solve the problems of long time for product cooling and demolding, increase in unsafe factors for demolding, affecting product production efficiency, etc. Improve detonation rate and detonation reliability, and eliminate the effect of non-detonation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

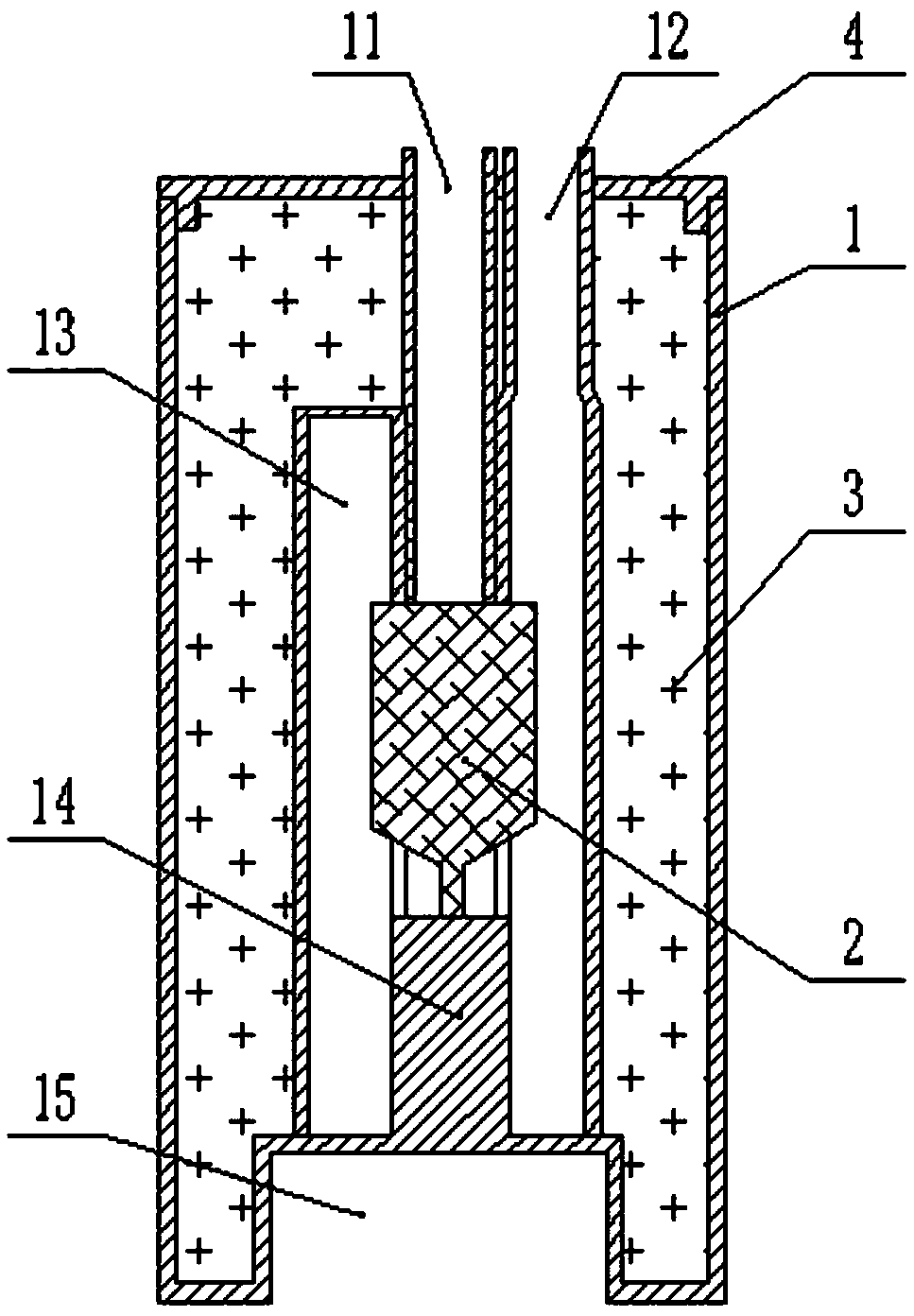

[0030] A structurally safe detonator, comprising: a shell 1, a detonating cartridge 2, a main charge 3 and an upper cover 4;

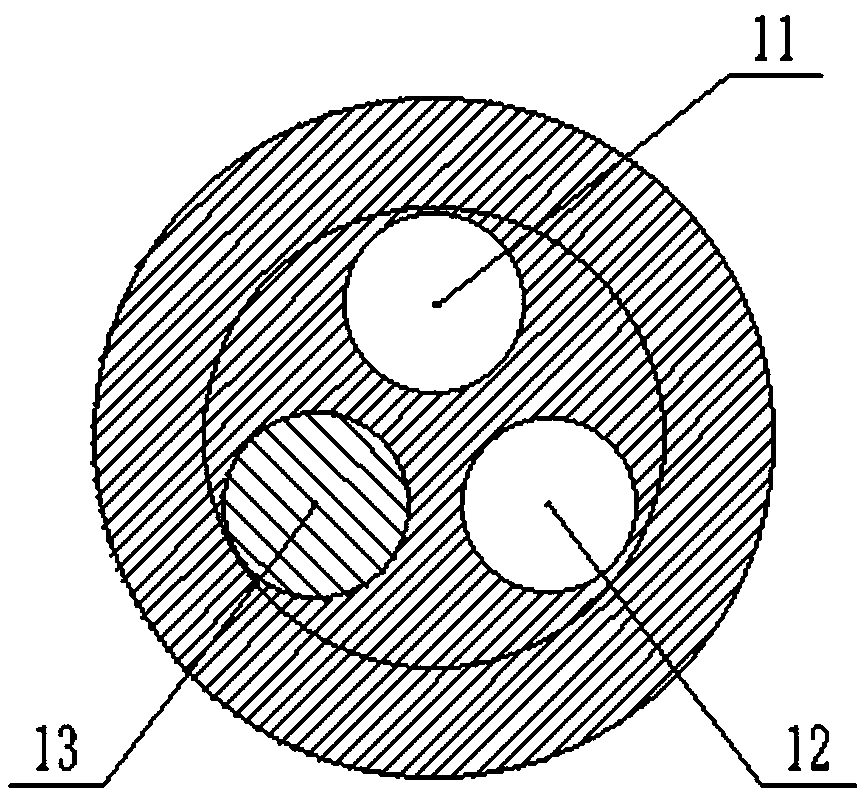

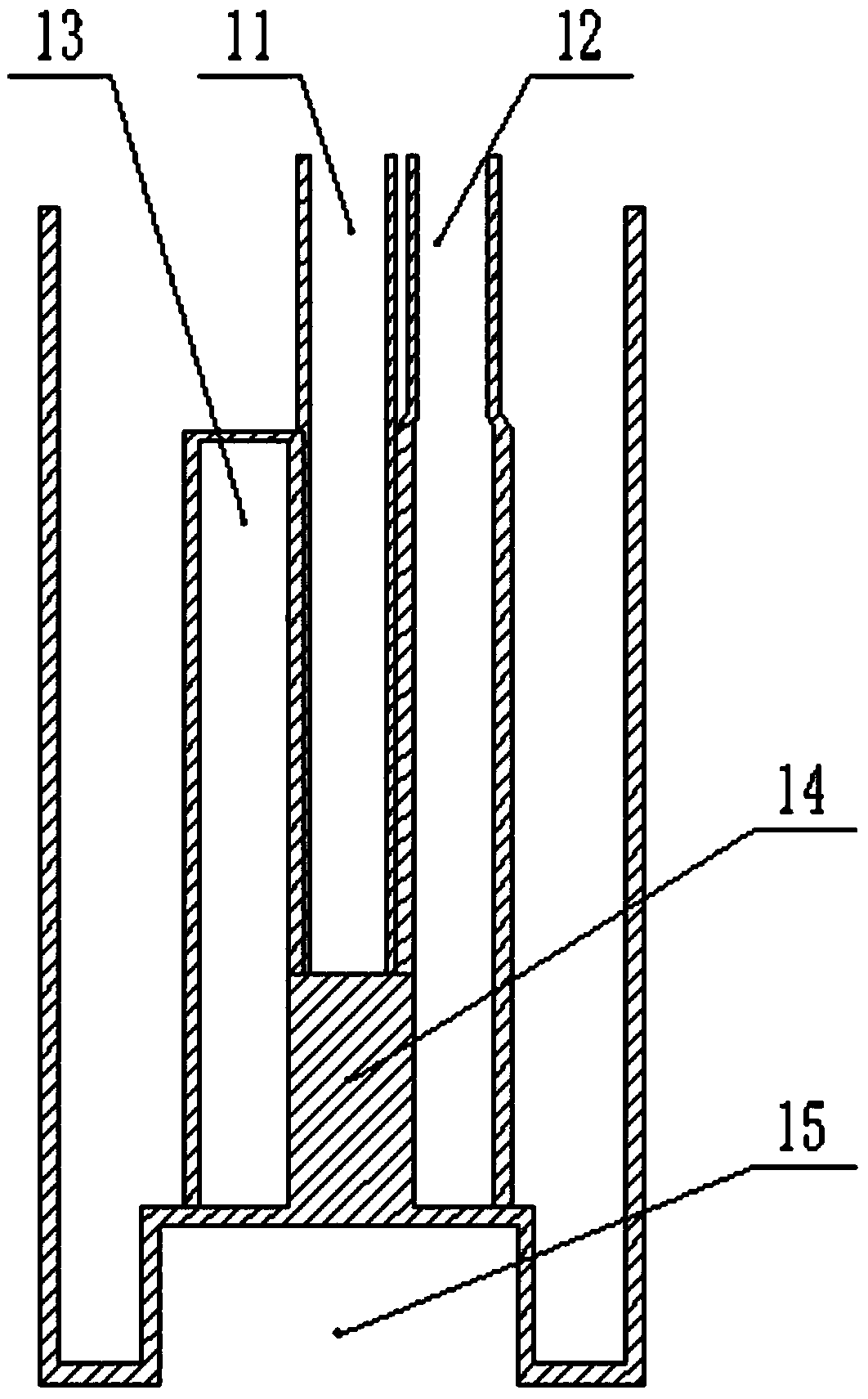

[0031] The structure of the housing 1 is as follows: a wire guide tube 11, a detonating cable guide tube 12, a detonator blind tube 13, a support positioning plate 14 and an energy gathering hole 15; the housing 1 is a columnar structure with an open upper end and a closed lower end , the casing 1 is provided with the wire conduit 11 and the detonating cord conduit 12 that pass through the casing 1, the casing 1 is provided with the detonator blind tube 13 with an open bottom end, so The supporting positioning plate 14 is arranged between the detonating cable passing tube 12 and the detonator blind tube 13, the wire guiding tube 11 of the housing 1, the detonating cable passing tube 12, the detonating cap blind tube 13 and the supporting positioning plate 14 is integrally formed, and a cavity is provided inside the bottom of the housing 1, and the cavi...

Embodiment 2

[0043] A structurally safe detonator, comprising: a shell 1, a detonating cartridge 2, a main charge 3 and an upper cover 4;

[0044] The structure of the housing 1 is as follows: a wire guide tube 11, a detonating cable guide tube 12, a detonator blind tube 13, a support positioning plate 14 and an energy gathering hole 15; the housing 1 is a columnar structure with an open upper end and a closed lower end , the casing 1 is provided with the wire conduit 11 and the detonating cord conduit 12 that pass through the casing 1, the casing 1 is provided with the detonator blind tube 13 with an open bottom end, so The supporting positioning plate 14 is arranged between the detonating cable passing tube 12 and the detonator blind tube 13, the wire guiding tube 11 of the housing 1, the detonating cable passing tube 12, the detonating cap blind tube 13 and the supporting positioning plate 14 is integrally formed, and a cavity is provided inside the bottom of the housing 1, and the cavi...

Embodiment 3

[0056] A structurally safe detonator, comprising: a shell 1, a detonating cartridge 2, a main charge 3 and an upper cover 4;

[0057] The structure of the housing 1 is as follows: a wire guide tube 11, a detonating cable guide tube 12, a detonator blind tube 13, a support positioning plate 14 and an energy gathering hole 15; the housing 1 is a columnar structure with an open upper end and a closed lower end , the casing 1 is provided with the wire conduit 11 and the detonating cord conduit 12 that pass through the casing 1, the casing 1 is provided with the detonator blind tube 13 with an open bottom end, so The supporting positioning plate 14 is arranged between the detonating cable passing tube 12 and the detonator blind tube 13, the wire guiding tube 11 of the housing 1, the detonating cable passing tube 12, the detonating cap blind tube 13 and the supporting positioning plate 14 is integrally formed, and a cavity is provided inside the bottom of the housing 1, and the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com