Same-body different-diameter reverse spiral screw fastening assembly not loose permanently

A screw tightening and reducing technology, applied in the direction of threaded fasteners, screws, nuts, etc., can solve the problems of difficult bolt rod processing technology, loosening and falling off, difficult maintenance and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

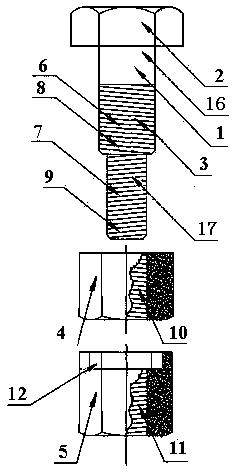

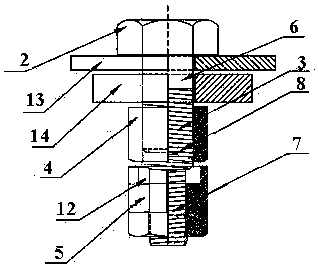

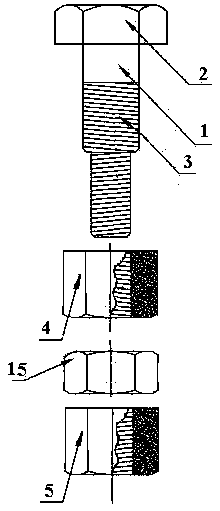

[0059] Such as figure 1 As shown, a same body and different diameter counter-rotating screw fastening assembly is made, the assembly includes a bolt 1, the bolt 1 includes a bolt head 2 and a screw 3, and a first nut 4 and a second nut 5 are also made; Now the screw 3 is made into two parts, the first rod section 6 and the second rod section 7, which are directly connected; the first rod section 6 is directly connected with the bolt head 2, and the second rod section 7 is directly connected to the first rod section. 6 is directly connected; the diameter of the first rod section 6 is greater than the diameter of the second rod section 7; the outer surfaces of the first rod section 6 and the second rod section 7 are both provided with external threads, the first The direction of the external thread on the rod section 6 is opposite to that on the second rod section 7; in this embodiment, the first rod section 6 is set to a large left-handed externally threaded rod 8, and the second...

Embodiment 2

[0065] Such as Figure 4 As shown, a tooth-lock type homogenous reducing counter-rotating screw fastening assembly is produced. On the basis of Example 1, the outer surface of the first nut 4 is divided into two parts: the outer polygonal prism 18 and the outer tooth cylinder 25, and the outer surface of the second nut is also divided into the outer polygonal prism 18 and Two parts of the outer surface tooth cylinder 25; the outer surface of the outer surface tooth cylinder 25 of the first nut and the outer surface of the outer surface tooth cylinder 25 of the second nut tooth cylinder are provided with an outer vertical tooth pattern 26 with exactly the same shape and specification; In addition, a cylindrical tooth clip 27 is provided, and an inner vertical tooth pattern 28 matching the outer vertical tooth pattern 26 is provided on the inner wall of the cylindrical tooth clip 27. In this way, a tooth-lock type concentric reducing screw fastening assembly is made. In this way...

Embodiment 3

[0071] Such as Figure 5 , 6 As shown in, 7, and 8, a nail-lock type concentric reducing screw fastening assembly is made. On the basis of embodiment 1, a pointed positioning screw 29 is also produced. The positioning screw 29 includes a nut and a stud. The stud is provided with an external thread; the outer end surface of the first nut 4 is provided There is a ring-shaped positioning groove 30 concentric with the nut hole. In this embodiment, the cross-section of the ring-shaped positioning groove 30 is set to a V shape; the second nut 5 is provided with one or more ring-shaped holes around the nut hole The penetrating screw holes 31 are arranged. In this embodiment, two screw holes 31 are provided. The inner wall of the screw holes 31 is provided with internal threads that match the external threads on the stud; thus, the present invention is made Nail lock type same body reducing screw fastening components.

[0072] In addition, the screw hole 31 can also be configured as a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com