While-drilling testing method and device for coal seam gas parameters

A technology for coal seam gas and testing device, which is applied in drilling equipment and methods, gas discharge, safety devices and other directions, can solve the problems of difficult drilling, inability to adjust the length of the drill bit, cumbersome and other problems, and achieves the effect of good and stable support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

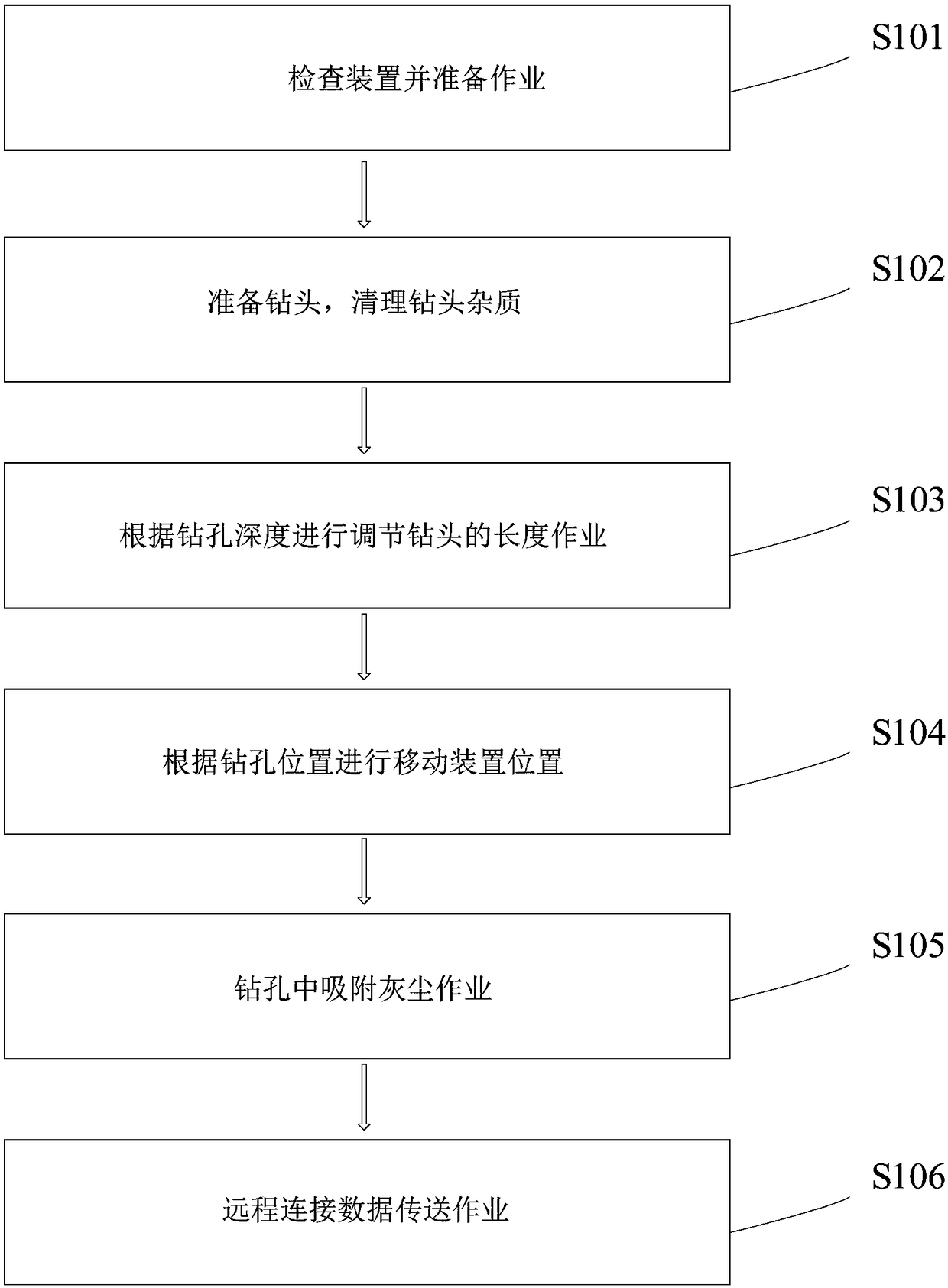

Method used

Image

Examples

Embodiment Construction

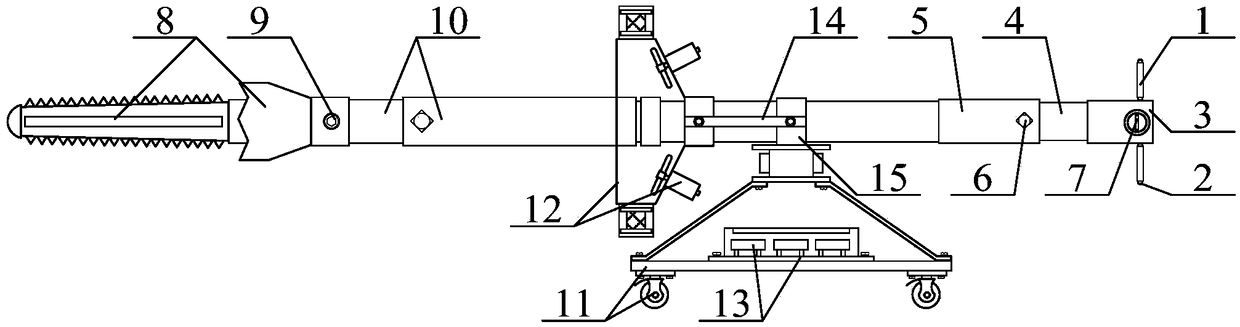

[0050] The present invention will be further described below in conjunction with accompanying drawing:

[0051] In the picture:

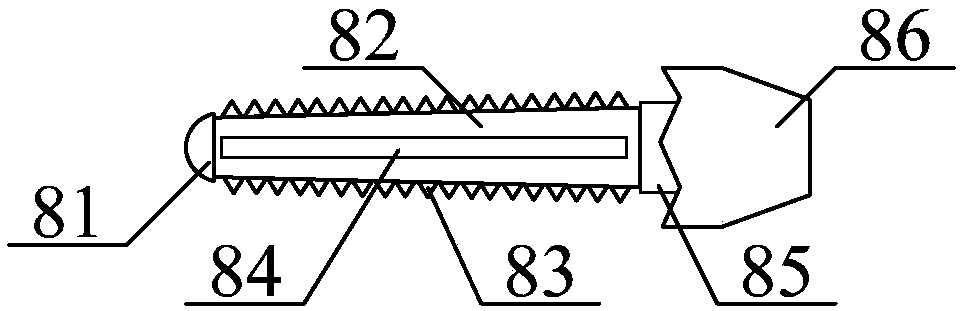

[0052] as attached figure 2 to attach Figure 8 Shown:

[0053] Coal seam gas parameter testing device while drilling, including hand sleeve 1, hand rod 2, connecting sleeve 3, docking shaft 4, connecting pipe 5, fastening bolt 6, in-line iron pin 7, detachable hard coal seam Auxiliary drilling drill bit structure 8, fixed hex socket socket bolt 9, adjustable length drilling extension rod structure 10, auxiliary mobile support transfer frame 11, dust auxiliary adsorption anti-splash shield structure 12 during drilling, remote data transmission and heat dissipation The cover structure 13, the connecting plate 14 and the fixed sleeve 15, the hand sleeves 1 are longitudinally socketed in the middle of the outer wall of the hand bar 2; the longitudinal inner ends of the hand bar 2 are respectively welded to the connecting sleeve The upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com