Insulation wall fabricated structure

A technology for thermal insulation walls and assembly structures, applied in the direction of thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of difficult to meet design requirements, no connection, difficult construction, etc., to achieve high assembly efficiency, fast and convenient assembly, The effect of improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

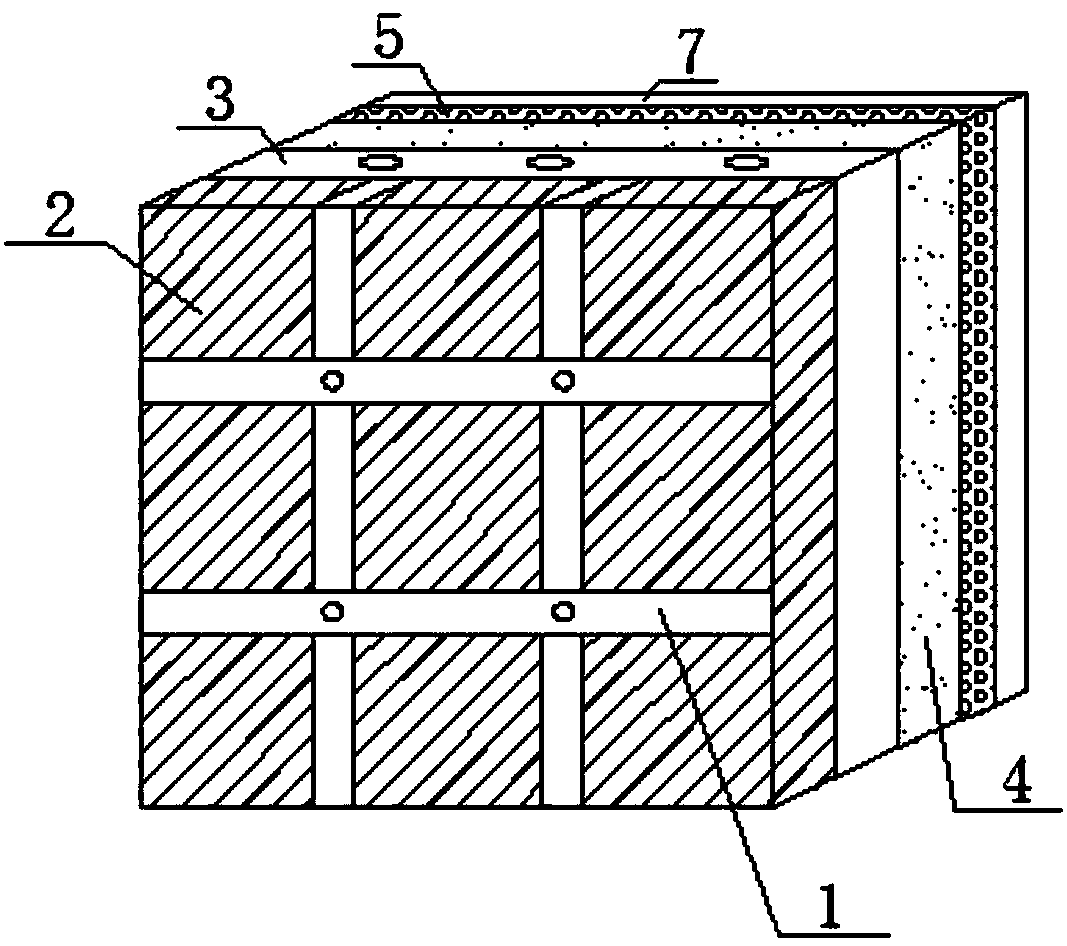

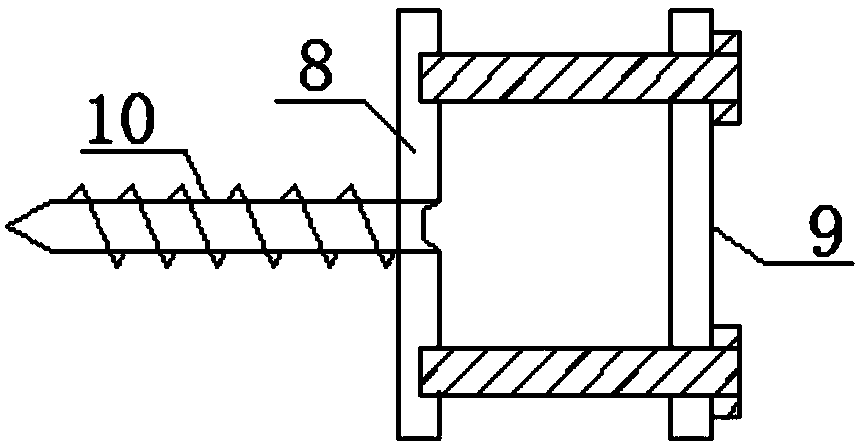

[0019] Such as figure 1 and figure 2 As shown, a thermal insulation wall assembly structure includes a thermal insulation wall rib 1, the outer surface of the thermal insulation wall rib 1 has a layer of anti-crack mesh cloth layer, and the structure of the anti-crack mesh cloth is used to further improve the thermal insulation The anti-crack performance of the wall improves the safety of the wall. The thermal insulation wall rib 1 is filled with a thermal insulation mortar layer 2, and the thermal insulation mortar layer 2 is filled with a layer of steel wire mesh. A steel wire mesh is arranged in the thermal insulation mortar layer 2. The strength and crack resistance of the thermal insulation mortar layer 2 are improved. The thermal insulation mortar layer 2 and the thermal insulation wall rib 1 are pre-cast and formed before use, which is convenient for direct assembly and use in the later stage. There is a layer on the inner surface of the thermal insulation wall rib 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com