Nutrient hole type cast-in-place greening concrete and construction method thereof

A technology of greening concrete and construction methods, applied in botany equipment and methods, excavation, foundation structure engineering, etc., can solve problems such as easy collapse, poor stability of concrete masonry structures, and damage to concrete masonry structures, so as to improve the overall Structural strength and high construction work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

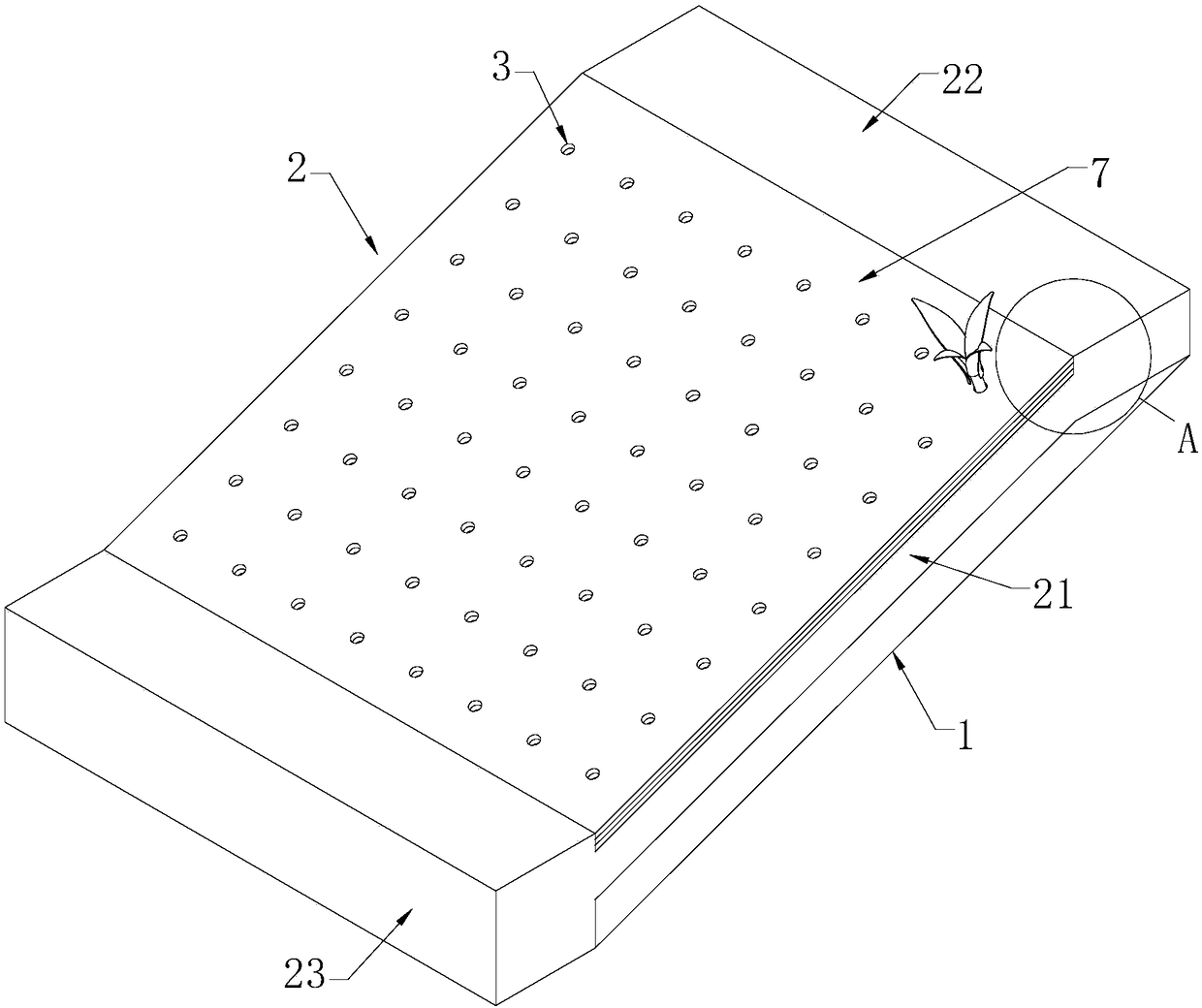

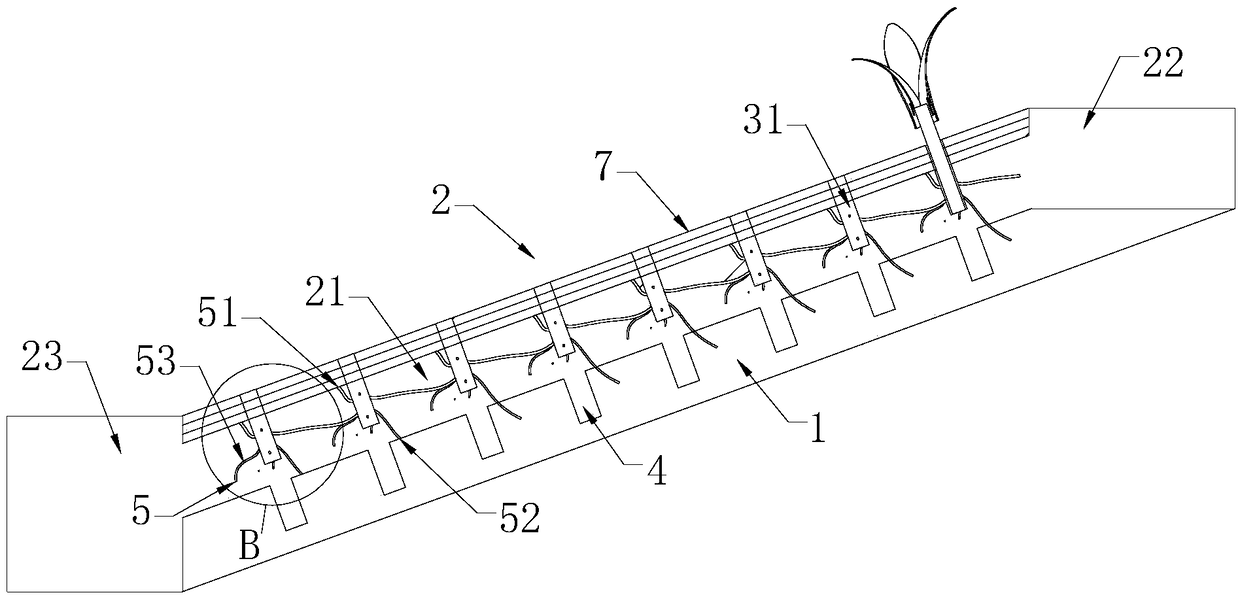

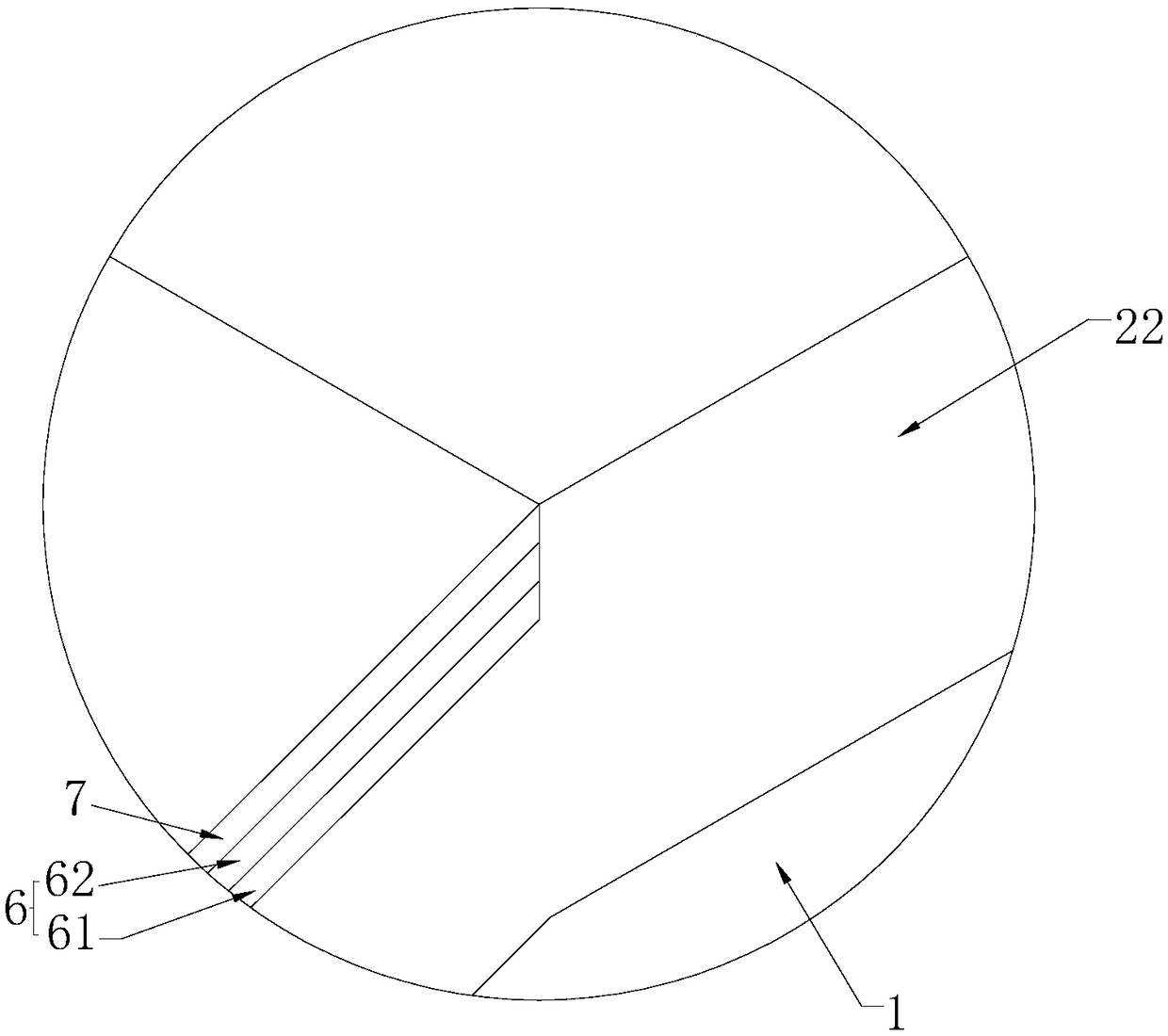

[0037] combine figure 1 and figure 2 As shown, a green slope protection concrete structure includes a slope protection 1 and a concrete layer 2 formed on the outer surface of the slope protection 1 by pouring in-situ greening concrete. Concrete layer 2 is vertically provided with nutrient hole 3 toward slope protection 1, and nutrient hole 3 does not run through concrete layer 2, and is filled with nutrient hole 3 soil in nutrient hole 3 to form nutrient hole soil layer 31, and the root system of greening vegetation takes root in this Nutrient holes in the soil layer 31. The concrete layer 2 between the nutrient hole 3 and the slope protection 1 extends vertically toward the slope protection 1 to form a concrete columnar body 4, and the concrete columnar body 4 is plugged and fixed inside the slope protection 1, that is, the greening vegetation and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com