Concrete hinge joint structure provided with intersecting shearing-resistant reinforcing steel bars and construction method of concrete hinge joint structure

A technology for shearing steel bars and concrete, which is applied in bridge construction, erection/assembly of bridges, bridge parts, etc. It can solve the problems of poor shear resistance and inconvenient construction, and achieve the effects of ensuring comfort, simplifying construction, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

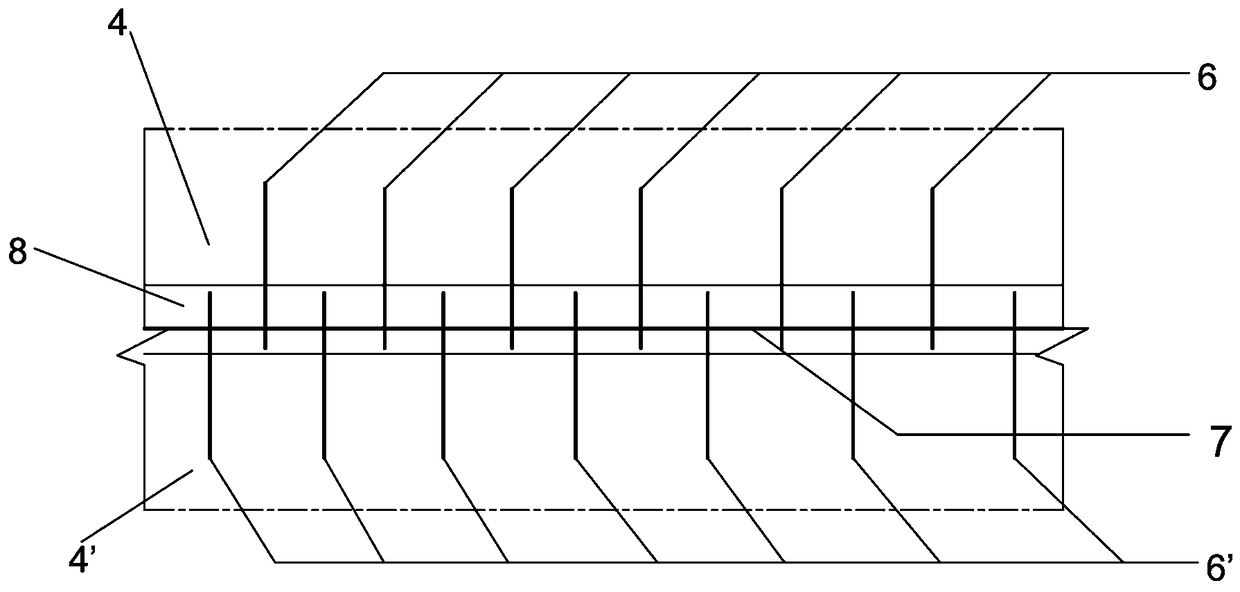

[0036] Such as Figure 1-Figure 3 As shown, a concrete hinged joint structure with intersecting shear reinforcement, including the joint body 8 formed by connecting the bottom of the first hollow slab beam 4 and the second hollow slab beam 4' with bumps 9 on both sides of the bottom, the first The tops of the first hollow slab girder 4 and the second hollow slab girder 4' are evenly arranged with a plurality of horizontal portal steel bars 3, and each horizontal portal steel bar 3 protrudes outward for a certain distance;

[0037] The upper part of the first hollow plate girder 4 is evenly arranged with a plurality of first upper high-strength steel bars 5 inclined upward at a certain angle with the horizontal direction along the extending direction of the hinged body 8, and the upper part of the second hollow plate girder 4' is along the extending direction of the hinged body 8 A plurality of second upper high-strength steel bars 5' inclined upward at a certain angle to the h...

Embodiment 2

[0046] A kind of construction method of above-mentioned hinge joint structure, this method comprises the following steps:

[0047] Step 1: Prefabricate multiple hollow slab beams;

[0048]Step 2: A plurality of transverse portal steel bars 3 are respectively preset on the top of the hollow slab girder, and the horizontal portal steel bars 3 extend a certain distance from the top surface of the hollow slab beam to provide corresponding conditions for the positioning and binding of relevant steel bars in the bridge deck laying layer;

[0049] Step 3: Embedding upper high-strength steel bars in the upper part of each hollow slab beam, and burying lower high-strength steel bars in the lower part of each hollow slab beam, so as to make multiple first hollow slab beams 4 and second hollow slab beams 4';

[0050] Step 4: Hoist the first hollow slab girder 4 and the second hollow slab girder 4' to a predetermined position, and connect the bumps 9 at the bottom of the first hollow slab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com