Culture excrement fermentation turning and throwing machine

A technology for turning and throwing manure, applied in the direction of organic fertilizer, organic fertilizer preparation, fertilization device, etc., can solve the problems of insufficient fineness, inability to pile up manure and throw, air pollution, etc., and achieve smooth surface, simple and reasonable structure , the effect of reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

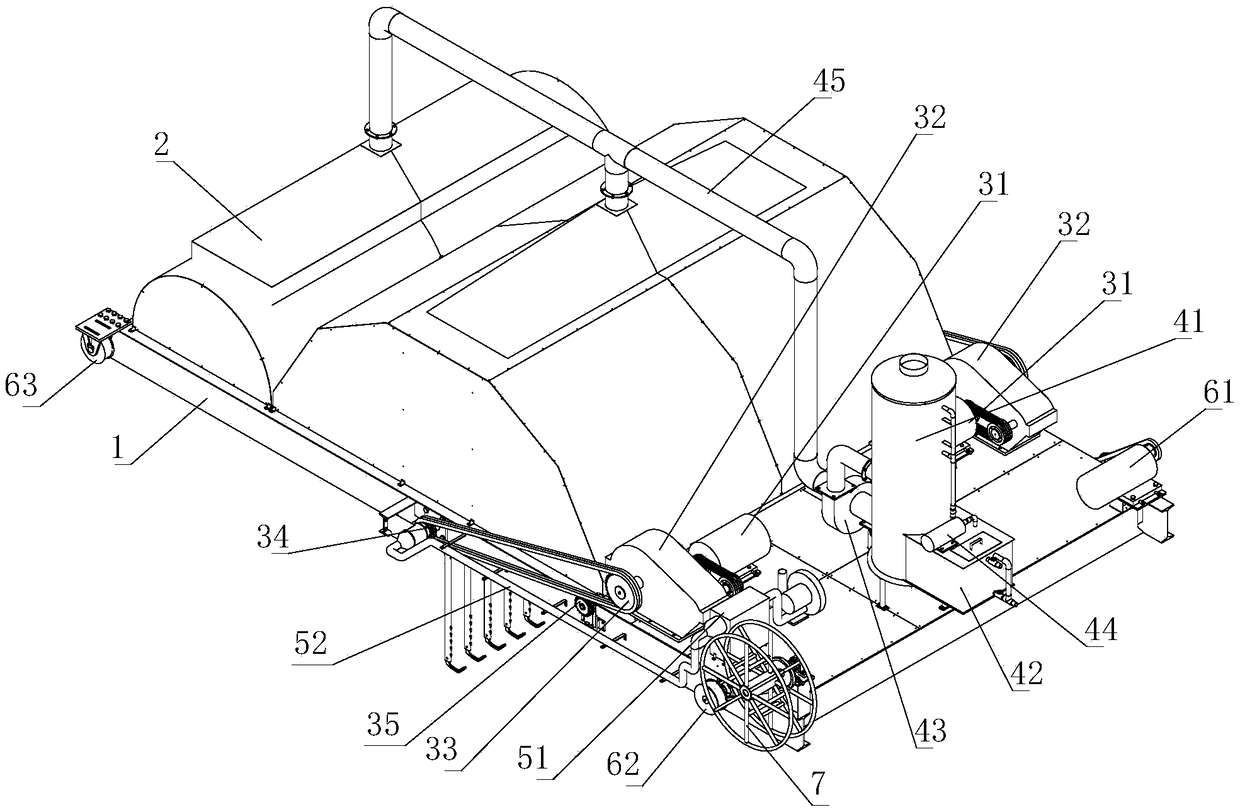

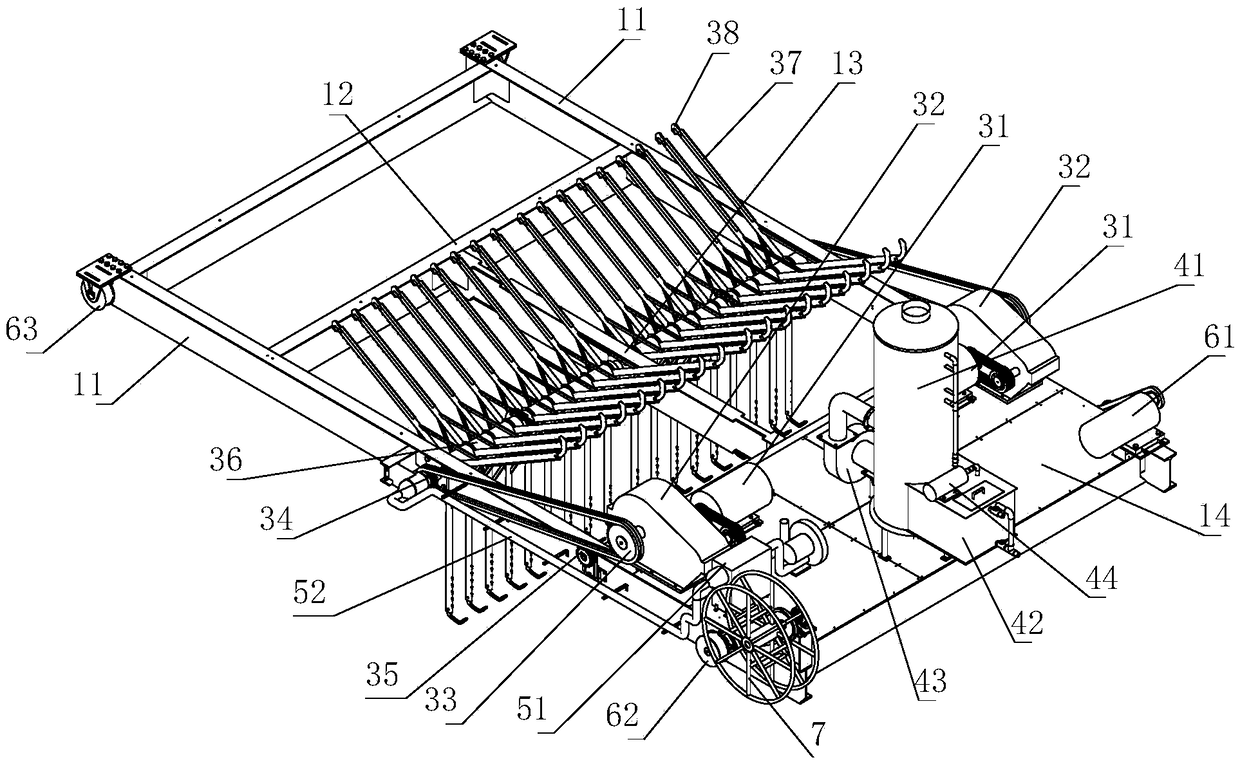

[0023] Such as Figure 1-2 As shown, a kind of farming excrement fermentation turning machine of the present invention comprises body 1, cover 2 and turning device, is generally provided with cement wall board on both sides of the fermenting tank of heaping manure, and the cement wall spacing of both sides is 3m to 4m, the height of the cement wall is 1m to 1.3m, and the I-steel guide rail is fixed above the cement wall. The pool buckle of the manure fermentation tank prevents the overflow of odor during the turning over process. The cover 2 adopts two covers, one large and one small, so as to reduce the weight and volume of a single cover, and it is more convenient to move, install and disassemble.

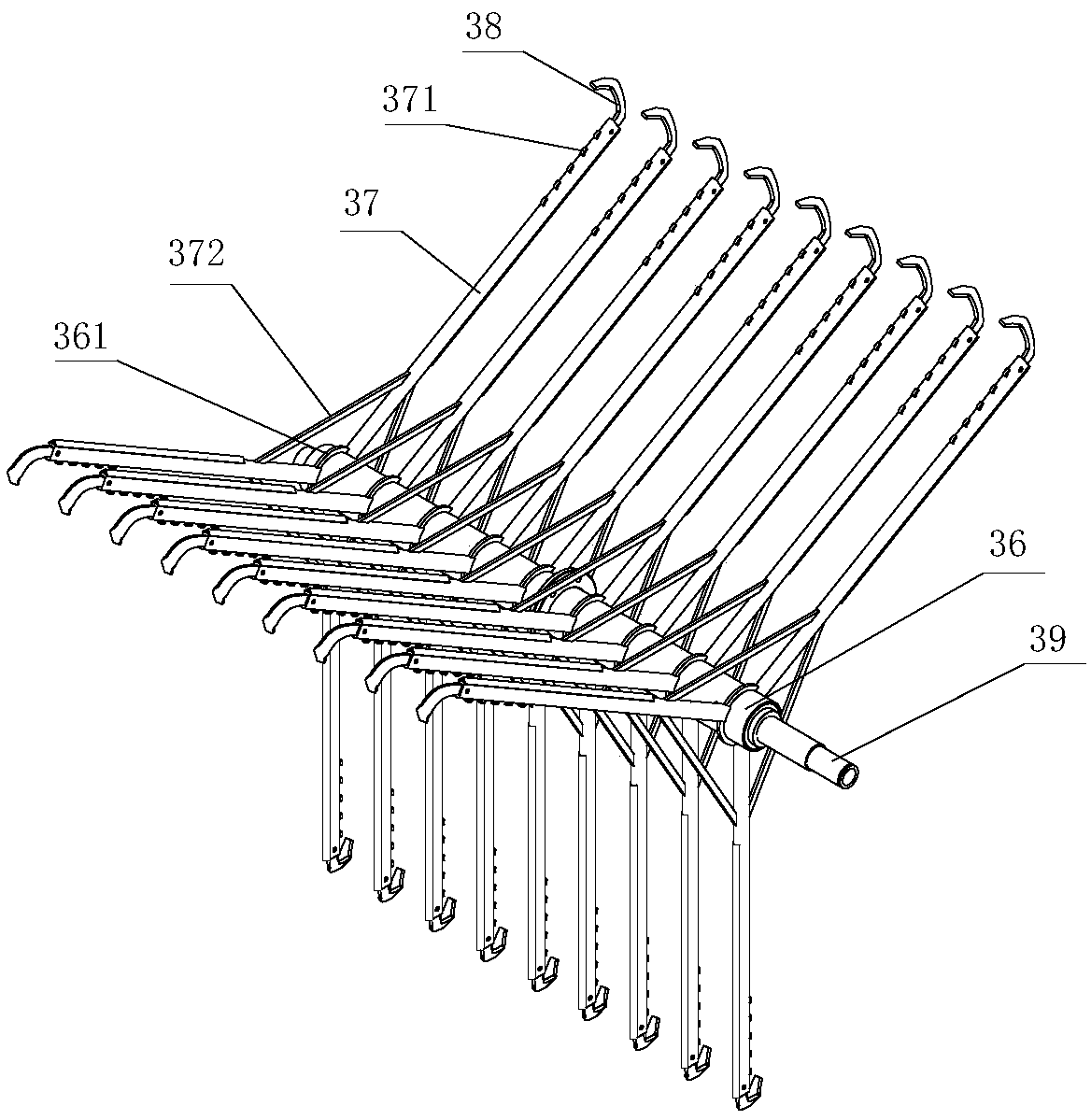

[0024] to combine image 3 As shown, in the present embodiment, the main structure of the body 1 is welded by four I-beams. figure 2 Middle r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com