Cement paste as well as application, foamed cement system and preparation thereof

A foamed cement and cement slurry technology, applied in the field of foamed cement, can solve the problems of reducing the density of cement slurry, long thickening time, less gas generation, etc., and achieve good compression resistance and compressibility, good foaming performance and stability. Sex, the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

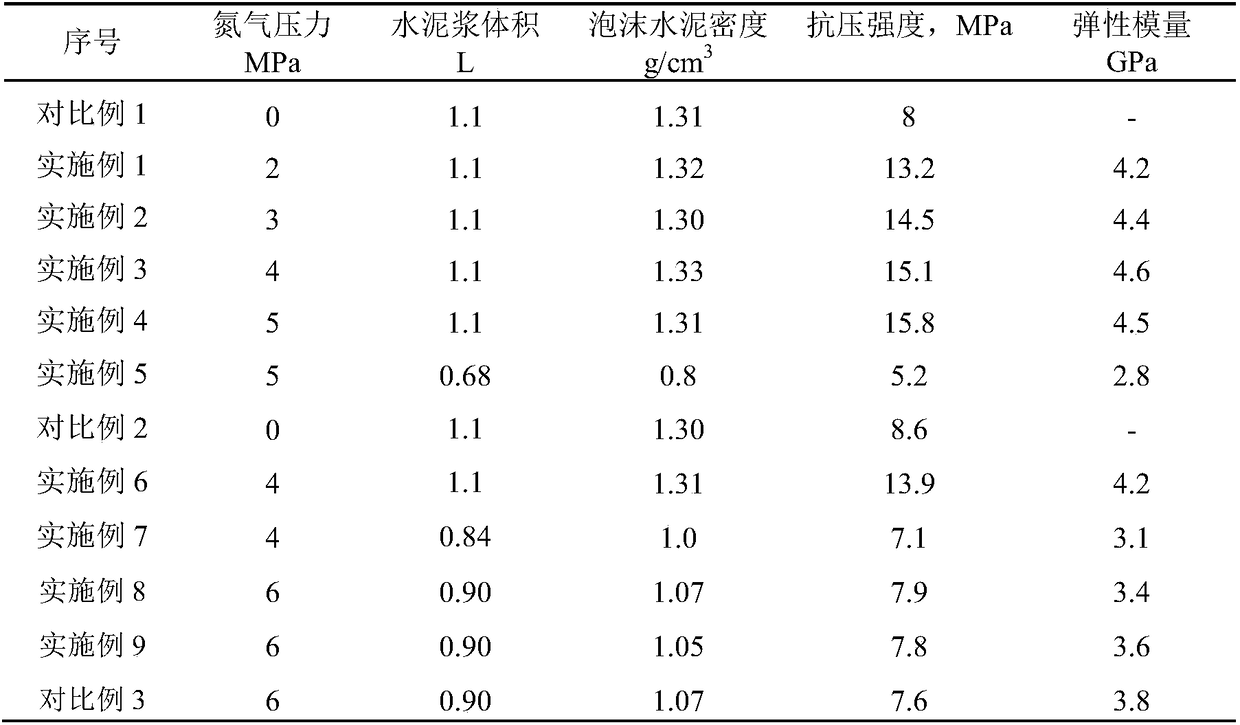

Embodiment 1

[0057] Weigh 100 parts of oil well G-grade Jiahua cement, 44 parts of water, 3 parts of DZJ-Y fluid loss reducer, 0.5 part of dispersant DZS, 0.1 part of xanthan gum foam stabilizer, and 1 part of calcium chloride enhancer, according to GB19139 "Oil Well Cement Test Method" formulated to a density of 1.88g / cm 3 The cement-based slurry was mixed evenly with 2.5 parts of HTW-1 protein composite foaming agent (produced by Henan Huatai New Materials Technology Co., Ltd.) to obtain cement slurry.

[0058] Pour 1.1L of cement slurry into the figure 1 In the I-shaped piston cylinder of the nitrogen injection preparation foam cement equipment shown, the stirring speed is 1000r / min. Turn on the air source, push the I-shaped piston cylinder to reciprocate, and the slurry circulates in the pipeline. At the same time, turn on the nitrogen source, adjust the nitrogen injection pressure to 2MPa, and circulate for 2-3 minutes. After the foaming is over, open the sampling barrel to take a s...

Embodiment 2

[0060] The experimental operation of Example 1 was repeated, but the difference was that the nitrogen injection pressure was adjusted to 3 MPa. The density of foam cement slurry and the test results of mechanical properties of cement stone are shown in Table 1.

Embodiment 3

[0062] The experimental operation of Example 1 was repeated, but the difference was that the nitrogen injection pressure was adjusted to 4MPa. The density of foam cement slurry and the test results of mechanical properties of cement stone are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com