A kind of preparation method of lithium-based bentonite

A lithium-based bentonite and bentonite technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as water separation, and achieve the effect of expanding the scope of application, low cost, and suitable for popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

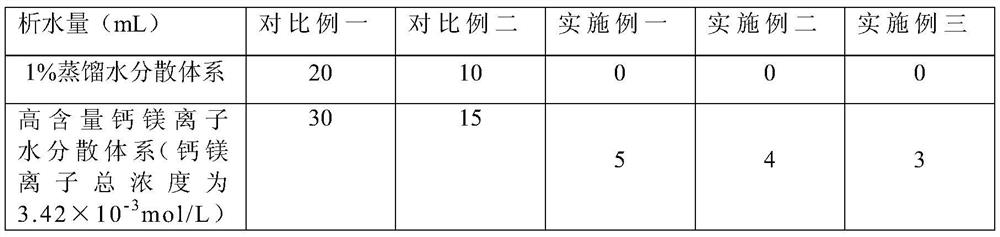

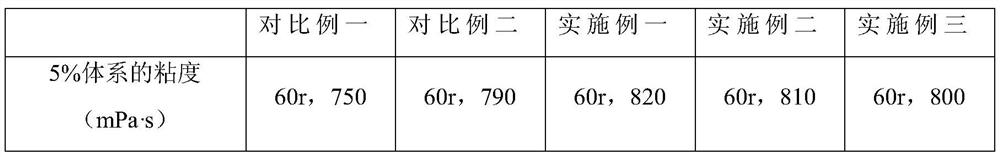

Examples

Embodiment 1

[0027] A preparation method of lithium-based bentonite, comprising the steps of:

[0028] (1) the bentonite raw material in the bentonite mineral is screened, and the bentonite raw material is obtained after impurity removal and purification;

[0029] (2) Grinding bentonite raw materials after drying to obtain powdered bentonite; the particle size of powdered bentonite is about 200 mesh; the main indicators of powdered bentonite are: montmorillonite content is 61.32%, swelling capacity is 10.23mL / g , Gum price 68mL / 15g soil;

[0030] (3) Add 20g of lithium carbonate to 1kg of powdered bentonite for lithiation; then add 20g of citric acid, stir at high speed in the mixer, heat up to 40°C while stirring, and then keep warm for 15min;

[0031] (4) cooling to room temperature to obtain the lithium-based bentonite.

Embodiment 2

[0033] A preparation method of lithium-based bentonite, comprising the steps of:

[0034] (1) the bentonite raw material in the bentonite mineral is screened, and the bentonite raw material is obtained after impurity removal and purification;

[0035] (2) Grinding bentonite raw materials after drying to obtain powdered bentonite; the particle size of powdered bentonite is about 200 mesh; the main indicators of powdered bentonite are: montmorillonite content is 61.32%, swelling capacity is 10.23mL / g , Gum price 68mL / 15g soil;

[0036] (3) Add 20g of lithium carbonate to 1kg of powdered bentonite for lithiation; then add 20g of oxalic acid, stir at high speed in the mixer, heat up to 40°C while stirring, and then keep warm for 15min;

[0037] (4) cooling to room temperature to obtain the lithium-based bentonite.

Embodiment 3

[0039] A preparation method of lithium-based bentonite, comprising the steps of:

[0040] (1) the bentonite raw material in the bentonite mineral is screened, and the bentonite raw material is obtained after impurity removal and purification;

[0041] (2) Grinding bentonite raw materials after drying to obtain powdered bentonite; the particle size of powdered bentonite is about 200 mesh; the main indicators of powdered bentonite are: montmorillonite content is 61.32%, swelling capacity is 10.23mL / g , Gum price 68mL / 15g soil;

[0042](3) Add 20g of lithium carbonate to 1kg of powdered bentonite for lithiation; then add 10g of oxalic acid and 10g of citric acid, stir at high speed in the mixer, heat up to 40°C while stirring, and then keep warm for 15min;

[0043] (4) cooling to room temperature to obtain the lithium-based bentonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com