Glass wine bottle capping device

A wine bottle and capping technology, which is applied in the direction of stopper feeding and stopper fixing, can solve the problems of bottle cap deformation and bottle damage, so as to protect the wine bottle, improve the sealing effect, and facilitate the fastening of the bottle cap Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

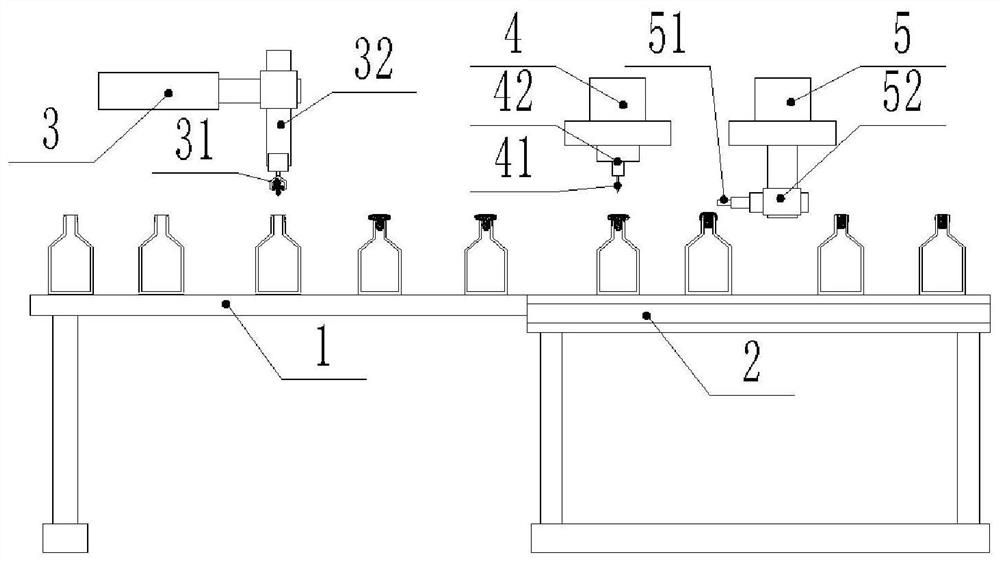

[0031] Such as figure 1 Shown: a glass wine bottle capping device, including a conveying unit 1 for transporting a wine bottle 7, a placement table 2 for placing a wine bottle 7, a clamping unit 3 for clamping a bottle cap 6, a first sealing mechanism 4, and a second sealing mechanism 5 and a control unit for controlling the operation of the conveying unit 1, the clamping unit 3, the first sealing mechanism 4 and the second sealing mechanism 5. In this embodiment, the control unit can adopt OMRON's CP1H-XA40DR-A programmable controller, which is easy to program and stable in performance.

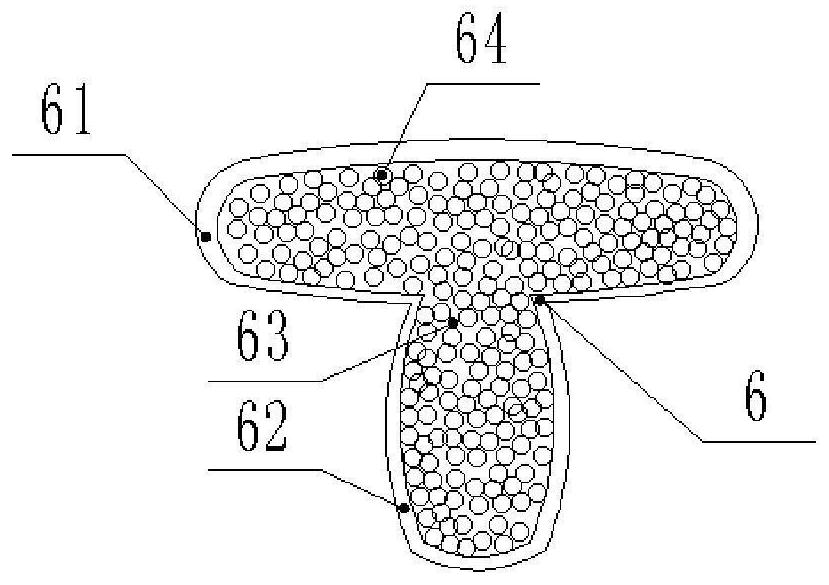

[0032] Such as figure 2 As shown: the bottle cap 6 in this embodiment is in the shape of a "T" and includes a head 61 and a bottle stopper 62 that is perpendicular to the head 61 and is fixedly connected. There is a communicating cavity 63 inside the head 61 and the bottle stopper 62. , The cavity 63 is also "T" shaped, the cavity 63 is filled with a filler 64, and a hole is opened at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com