Automatic clamping and conveying device

A clamping conveying and automatic technology, which is applied in the field of automatic clamping conveying devices, achieves the effects of low operating cost, reduced production labor, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

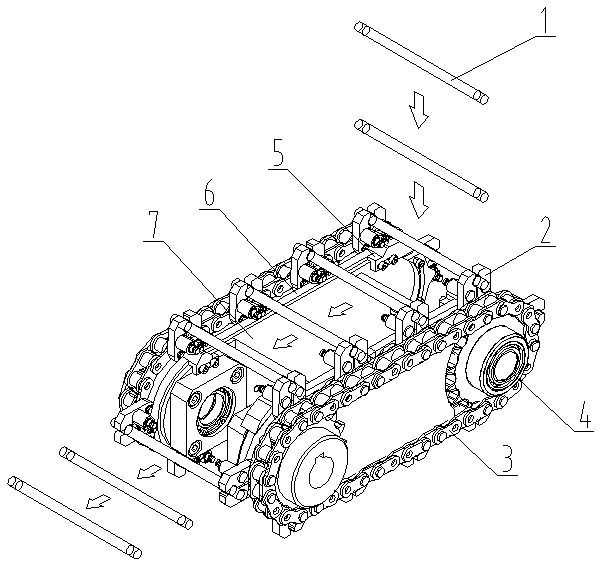

[0021] figure 1 , figure 2 The preferred embodiment of the present invention is shown, and its structure is composed of material 1, gripper 2, conveying chain head 3, conveying sprocket 4, bump 5, conveying track 6, and conveyor mounting plate 7.

[0022] The structural features of the specific embodiment of the present invention are:

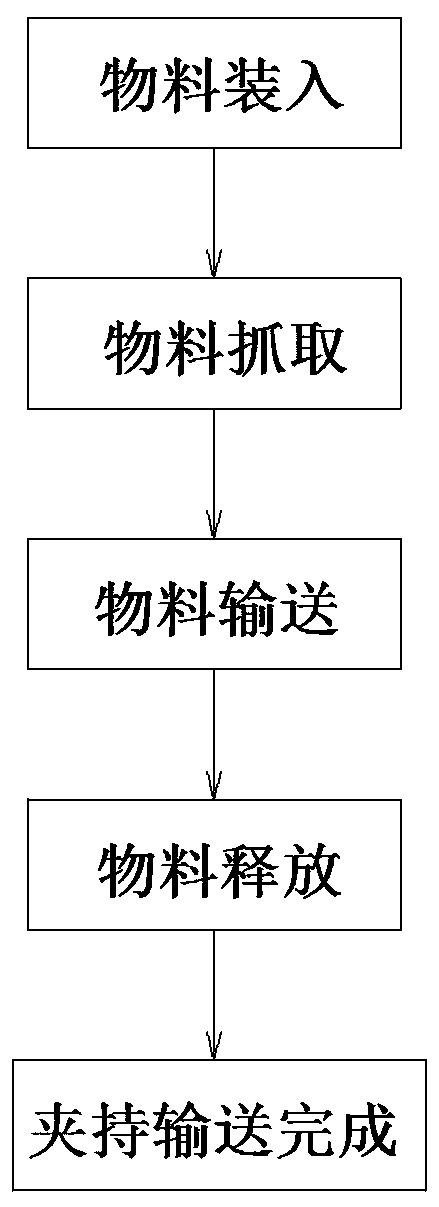

[0023] An automatic clamping and conveying device, which is mainly used for the assembly and use of paper continuous gluing, cutting, high-speed winding and packaging equipment, is characterized in that: the clamping and conveying device includes a material 1, a clamping gripper with rollers for picking up and placing materials 2. Conveyor chain 3, Conveyor sprocket 4 connected to the drive shaft, Protrusions 5 fixedly connected on the conveyor guide rail, Conveyor track 6 set on the conveyor mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com