Anti-pinch door, anti-pinch door sealing strip and vehicle using anti-pinch door

A technology of sealing rubber strip and anti-pinch door, which is applied in the direction of engine sealing, sealing device, vehicle parts, etc., can solve the problems of mis-opening the door, affecting the transmission of light signals, reducing the sealing performance of the cabin, etc., to achieve the effect of ensuring the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

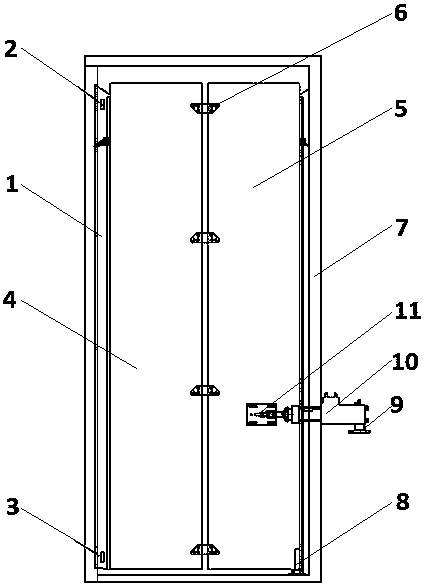

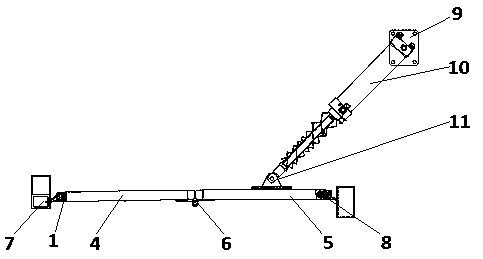

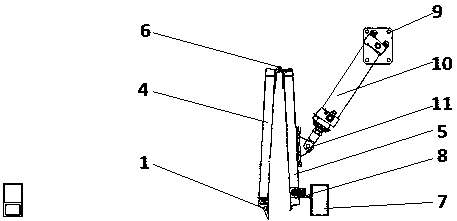

[0031] Embodiment 1: as Figure 1~4 As shown, the sealing rubber strip 1 includes a wedge-shaped structure 101 and a fixed connection bottom 102 of the door body. An optical signal channel 103 and a cavity 104 are processed in the fixed connection bottom 102 of the door body. The anti-pinch door is a folding door, and the door frame 7 is installed on the compartment. , the door body is the active door 5 and the driven door 4 respectively, and the folding door is used to save the running space of the door panel and the position occupied by the door panel after the door is opened. A plurality of hinges 6 are used to connect the two door panels, while the active door 5 and the door frame 7 are hinged through the pin shaft 8, and the driven door 4 and the sealing strip 1 are connected through a T-shaped slot 105, wherein the sealing strip The wedge-shaped structure 101 of 1 is sealed with the door frame 7, and the sealing rubber strip is made of rubber. The wedge-shaped structure ...

Embodiment 2

[0034] Embodiment 2: as Figure 5 As shown, the difference from Embodiment 1 is that each end face of the sealing rubber strip is adjusted from the curved surface in Embodiment 1 to a plane, which facilitates the mass production of the model for manufacturing the sealing rubber strip.

Embodiment 3

[0035] Embodiment 3: as Figure 6 As shown, the only difference from Embodiment 2 is that the cross section of the optical signal channel 103 is rectangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com