Preparation method of industrialized non-denaturing collagen II

A technology of collagen and collagen powder, applied in the field of bioengineering, can solve the problems of difficult large-scale production, cumbersome method steps, long process route, etc., and achieve the effect of facilitating post-processing, simple working hours, and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

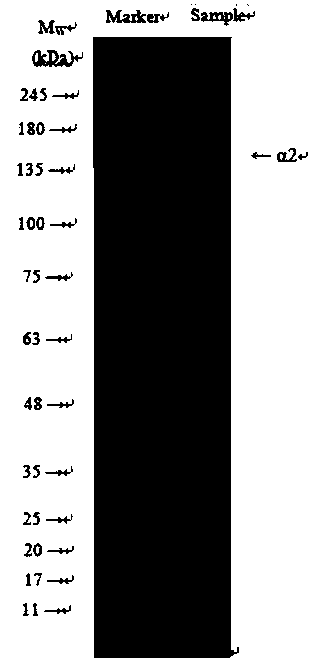

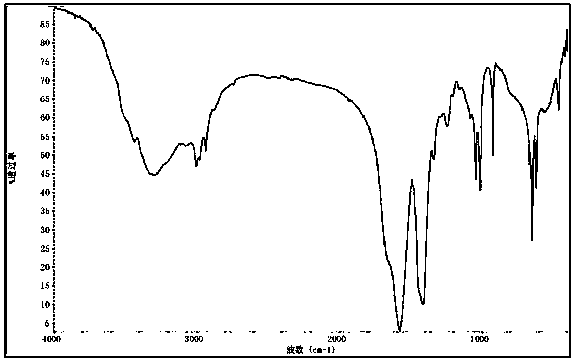

[0016] A method for preparing industrialized non-denatured II collagen, comprising the following steps: (1) cartilage pretreatment: after the cartilage is cleaned and fleshed, the cartilage is washed with H 2 o 2 Soak and disinfect for 18-24 hours, mash the treated cartilage with a tissue masher; (2) Alkaline extraction: soak the mashed cartilage in 0.1-4M lye at 12°C for 6-24 hours, Removal of soluble protein, fat and polysaccharide; (3) Separation and drying: separate the precipitate with a centrifuge, pulverize the precipitate with a pulverizer, add water to suspend it, and freeze-dry to obtain insoluble non-denatured II collagen powder. Wherein the lye is one of sodium hydroxide, calcium hydroxide or potassium hydroxide, the cartilage is chicken cartilage, and the centrifugal separation operating conditions of the centrifuge are 5000rpm, 4°C, and more than 10min.

Embodiment 2

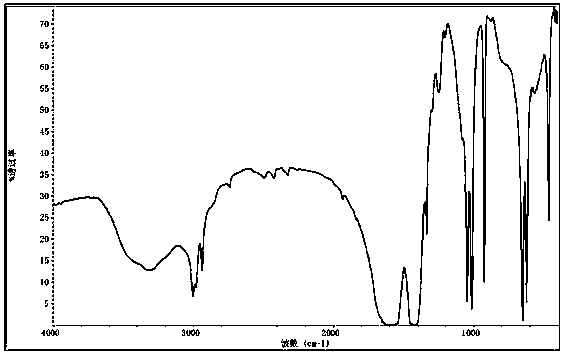

[0018] Embodiment 2 On the basis of Embodiment 1, the following steps are also included: placing the insoluble non-denatured II collagen powder obtained by freeze-drying in a reaction tank, adding 1 to 5 times the amount of protein powder in deionized water, and adding 1 to 5 times the amount of protein powder. 0.05-5% pepsin, adjust the pH value to 1.5-4.5, enzymatically hydrolyze at 4°C for 24-72 hours, centrifuge or filter the enzymolyzed solution, and freeze-dry the supernatant to obtain soluble non-denatured II collagen powder.

Embodiment 3

[0020] Embodiment 3 On the basis of Embodiment 1, the following steps are also included: placing the insoluble non-denatured II collagen powder obtained by freeze-drying in a reaction tank, adding 1 to 5 times the amount of protein powder in deionized water, and adding 1 to 5 times the amount of protein powder. 0.05-5% pepsin, adjust the pH value to 1.5-4.5, enzymatically hydrolyze at 20°C for 24-72 hours, centrifuge or filter the enzymolyzed solution, and freeze-dry the supernatant to obtain soluble non-denatured II collagen powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com