Finishing device capable of recording number of yarns

A sorting device and quantity technology, which is applied in the direction of thin material handling, transportation and packaging, and delivery of filamentous materials, etc., can solve the problems of error-prone memory, non-adjustable height, lack of counting function, etc., and achieve the effect of avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

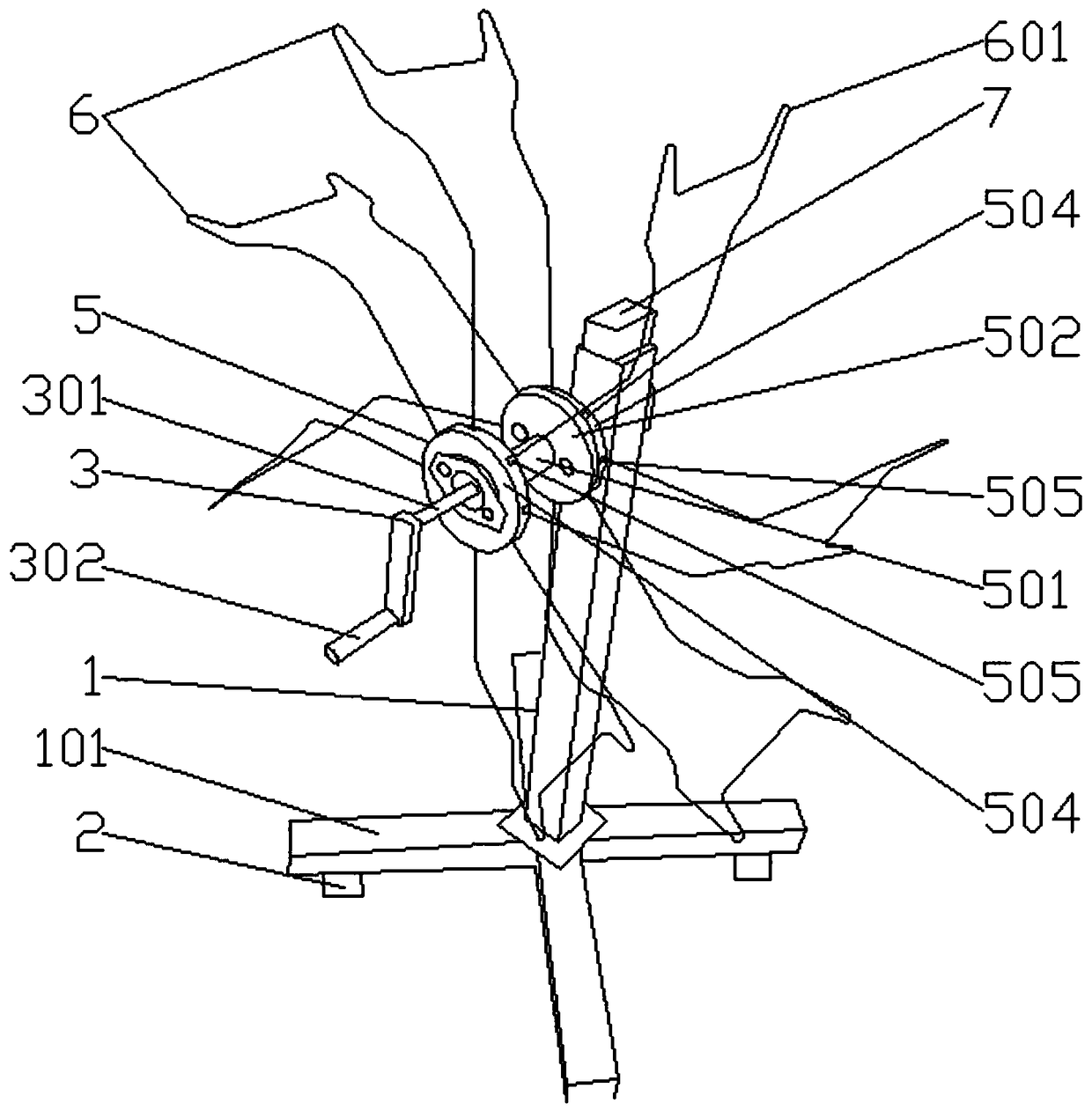

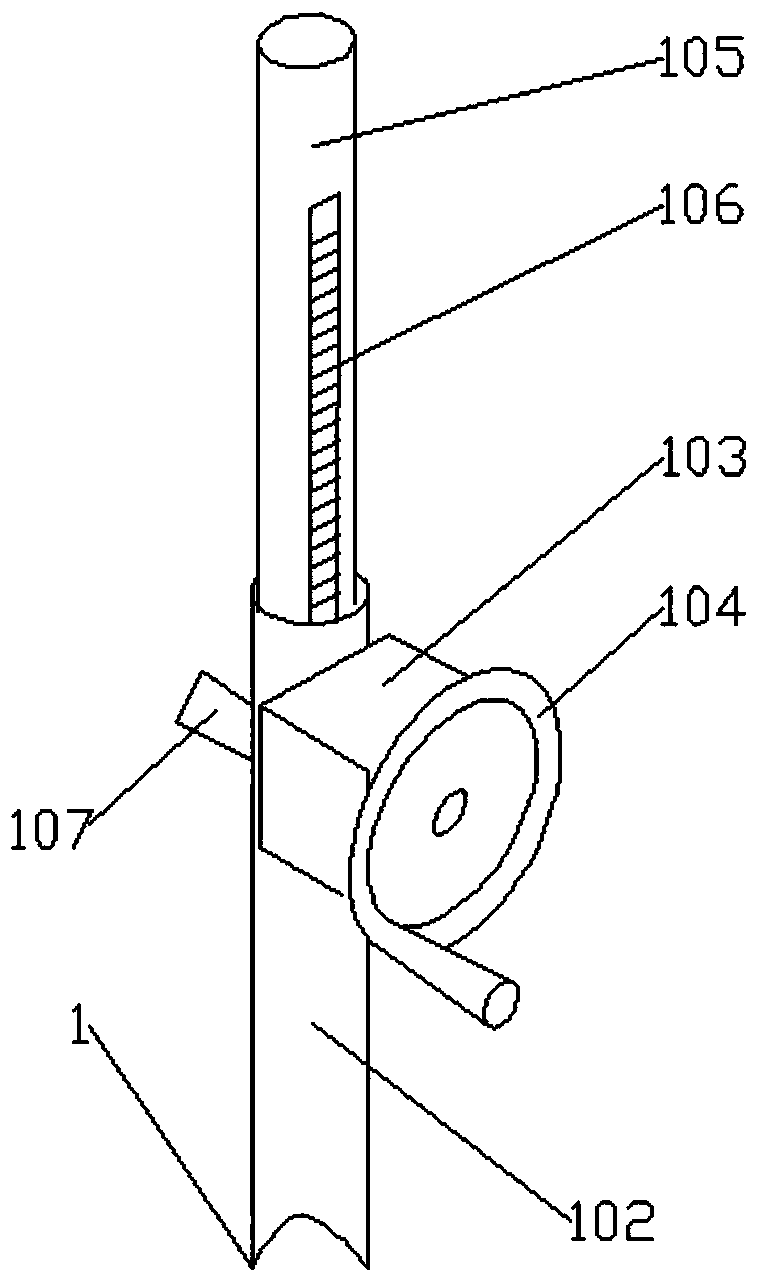

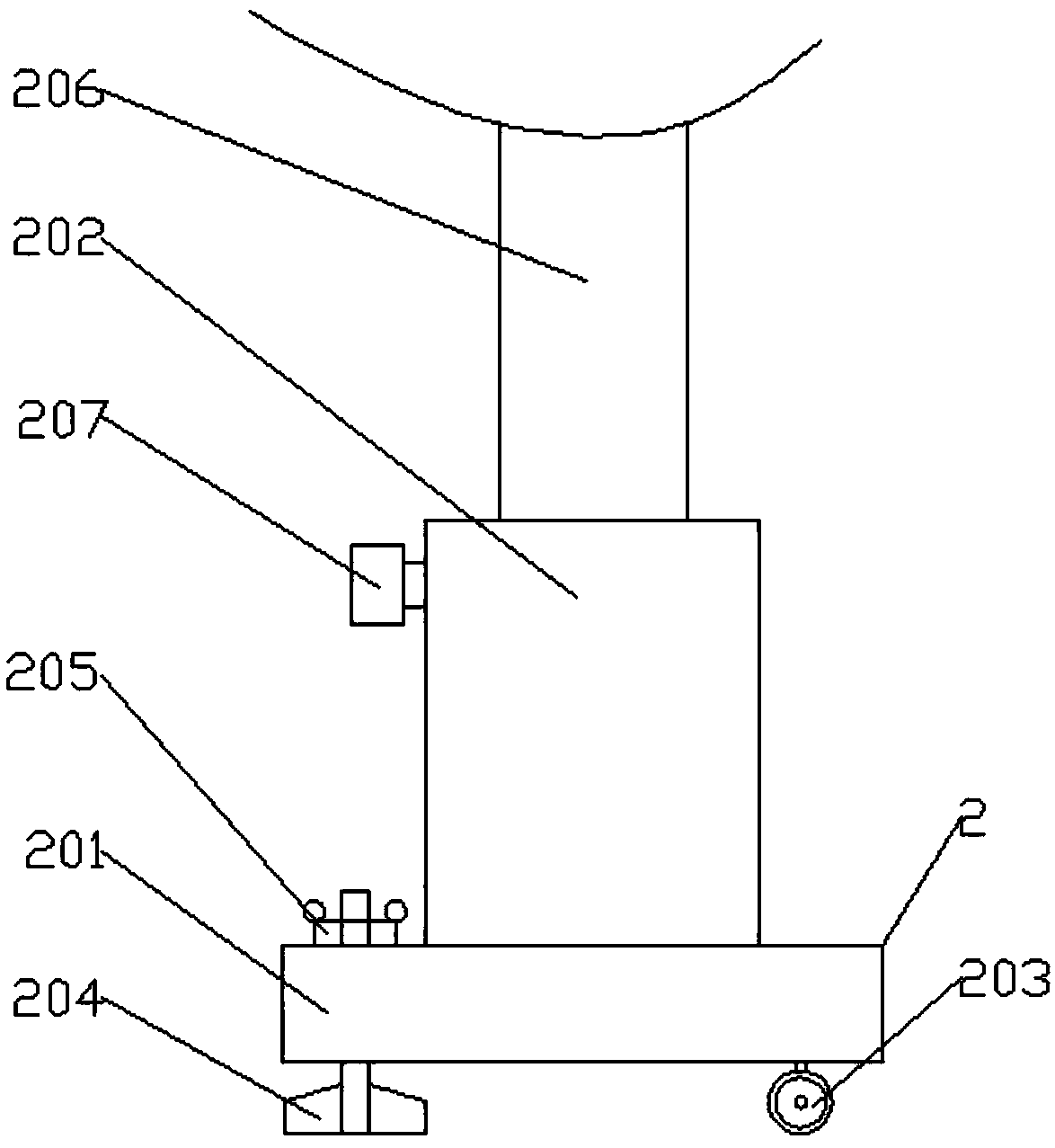

[0043] Such as figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15The shown finishing device capable of recording the number of yarns includes an elevating support 1, a rotating mechanism 3 arranged on the upper part of the elevating support, a connecting piece 4 arranged on the rotating mechanism, a wheel assembly 5 arranged on the rotating mechanism, a set Some shelving assemblies 6 on the roulette assembly and the mechanical counting mechanism 7 that is arranged on the top of the lifting support, the connector is connected with the mechanical counting mechanism; the lifting support includes a base 101 and a support cylinder 102 arranged on the base, and There is a gear box 103,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com