Mold combining mechanism of injection machine

A mold clamping mechanism and injection machine technology, applied in the field of injection molding machines, can solve problems such as uneven distribution of long-term clamping force, affecting the quality of injection molded products, poor exhaust, etc., to achieve light weight, reduce deformation, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

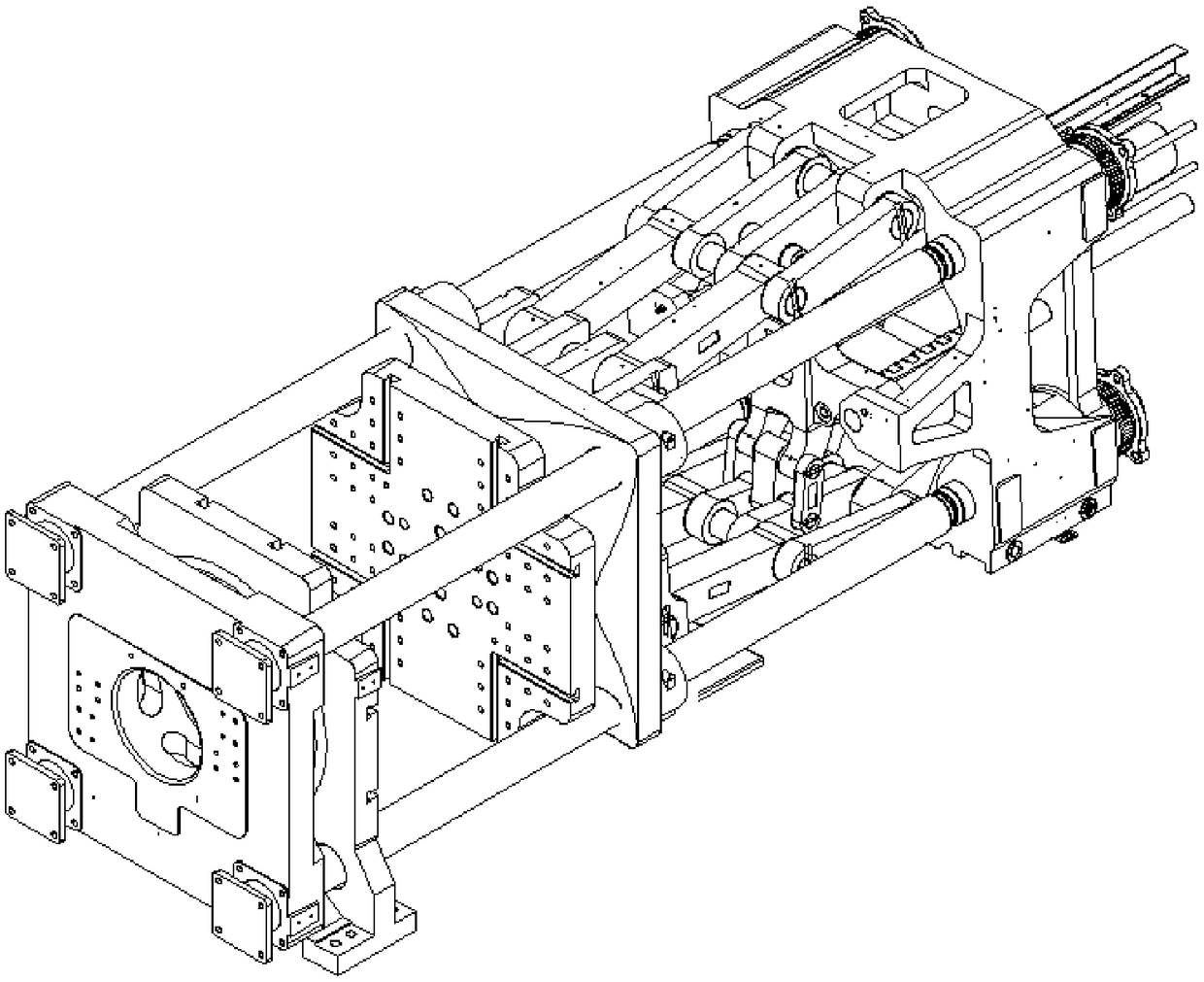

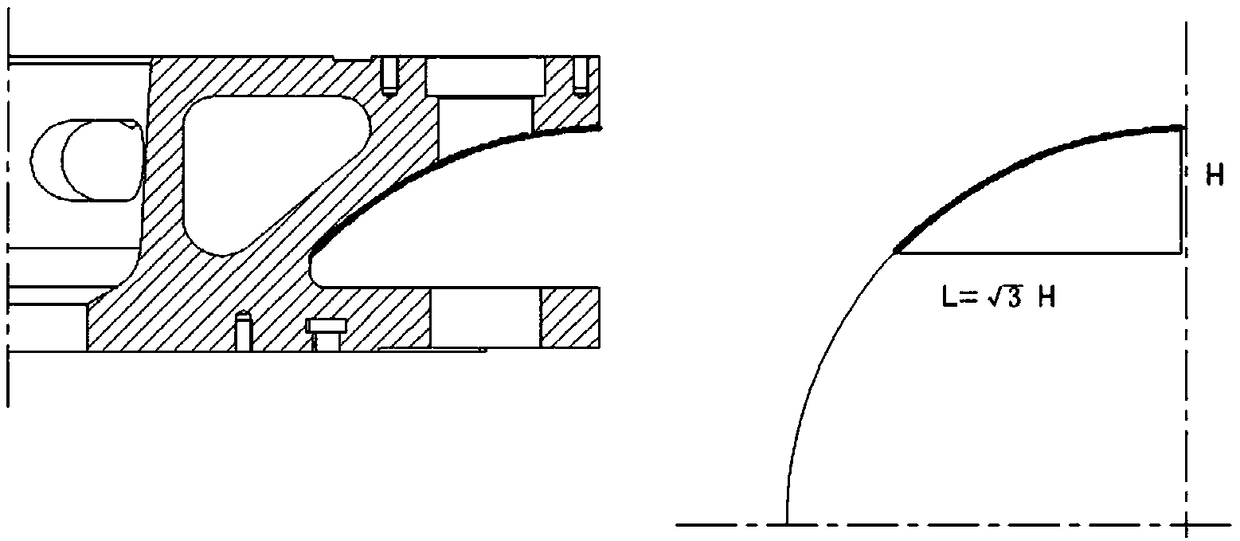

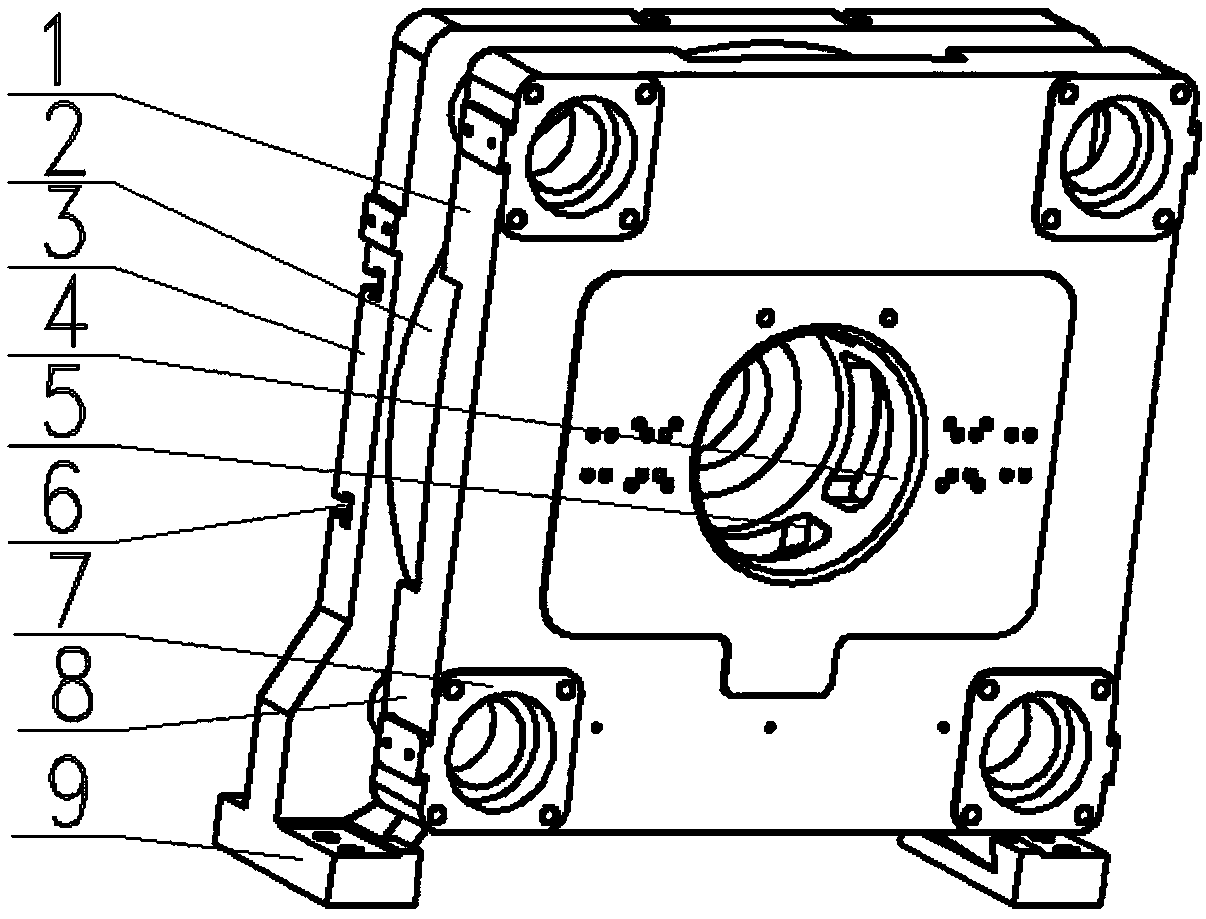

[0022] A mold clamping mechanism of an injection machine of the present invention, such as image 3 , 4 , 5, 6, and 7, including mold clamping mechanism, front template and movable template, front template plate includes front template clamping force loading plate 1, front template annular hollow arc surface support 2, front template mold mounting plate 3, dynamic The template includes a movable template mold mounting plate 10 , a movable template annular hollow arc surface support 11 and a movable template clamping force loading plate 12 . Among them, there are tie rod guide seats 7 at the four corners of the front formwork clamping force loading plate 1, and support feet 9 are provided under the front formwork. There are tie rod holes 14 at the four corners of the loading plate 12, the lower surface of the movable template clamping force loading plate 12 is connected with the annular hollow arc surface support 11 of the movable template, and there is a sliding foot 13 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com