Moving trolley for conveying main fixture on main welding line for automobile welding

A technology of main fixtures and trolleys, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as limitations of drive systems and safety measures, inadequate protection measures, and low positioning accuracy, and achieve good practical use and promotion value. The effect of safe and reasonable structural design and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

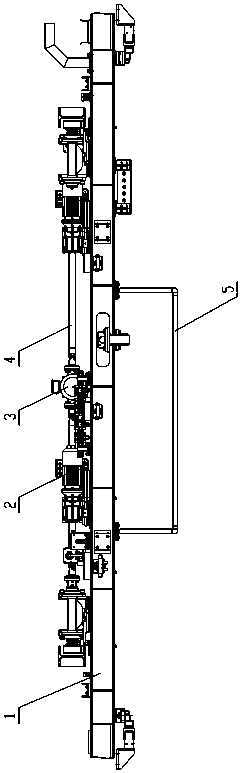

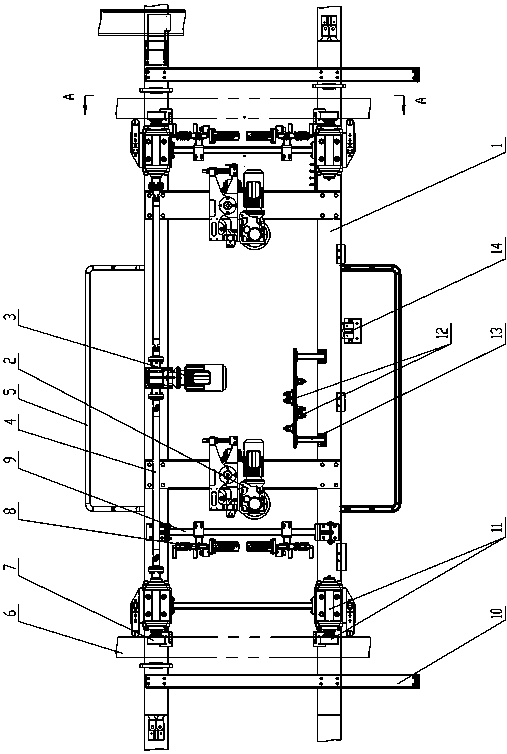

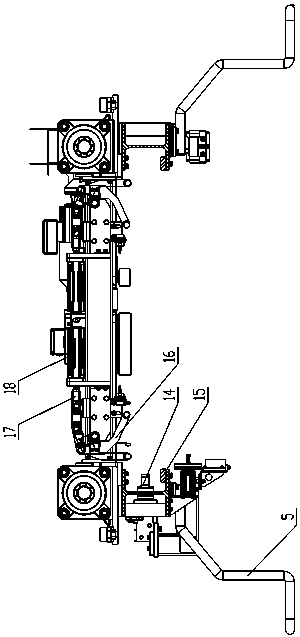

[0018] see Figure 1-Figure 3 , the present invention is a traveling trolley used for conveying main fixtures of main welding wires for automobile welding, which has a trolley frame 1, and a driving wheel device and a driven wheel device 11 are arranged on the upper part of the trolley frame. The bottom is provided with a spreader trolley track 15 arranged perpendicular to the running direction of the trolley, and the spreader trolley track is made of I-beam; the left and right sides of the trolley frame are respectively provided with a connecting pipe 9, each A set of spreader trolley limit opening and closing devices 8 are respectively provided on the front and rear of the root connecting pipe; a set of spreader trolley drive devices 2 are respectively provided on the left and right sides of the bottom of the traveling vehicle frame, and the spreader trolley drive device is used to drive the loading The operation of the spreader trolley with the main clamp; a detection frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com