High-speed lamination automation system of transformer core

A technology of transformer iron core and automation system, applied in the field of automation system, can solve the problems of low lamination accuracy, low production efficiency, low degree of automation, etc., and achieve the effects of high precision, accurate stacking, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

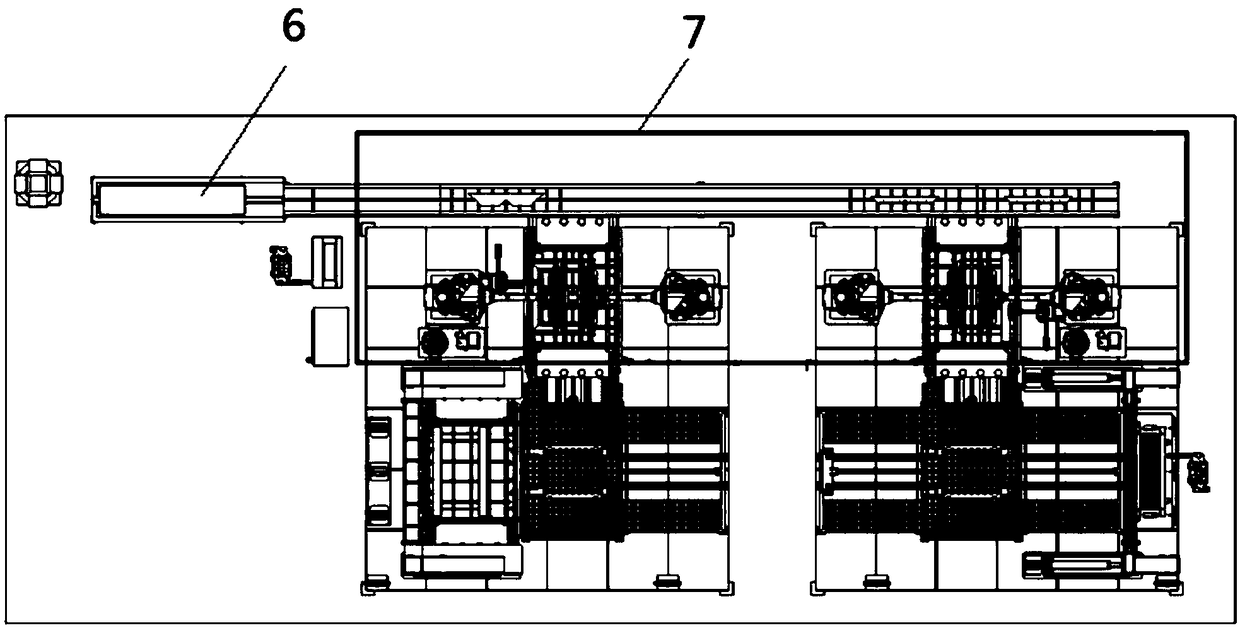

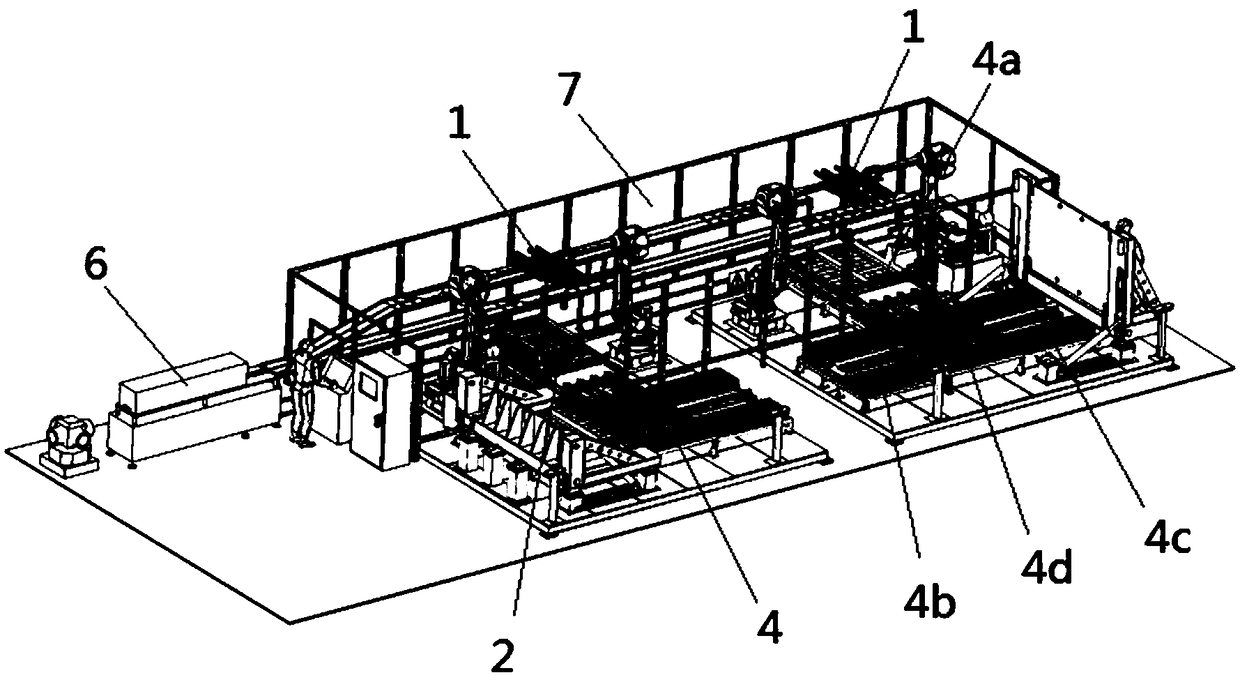

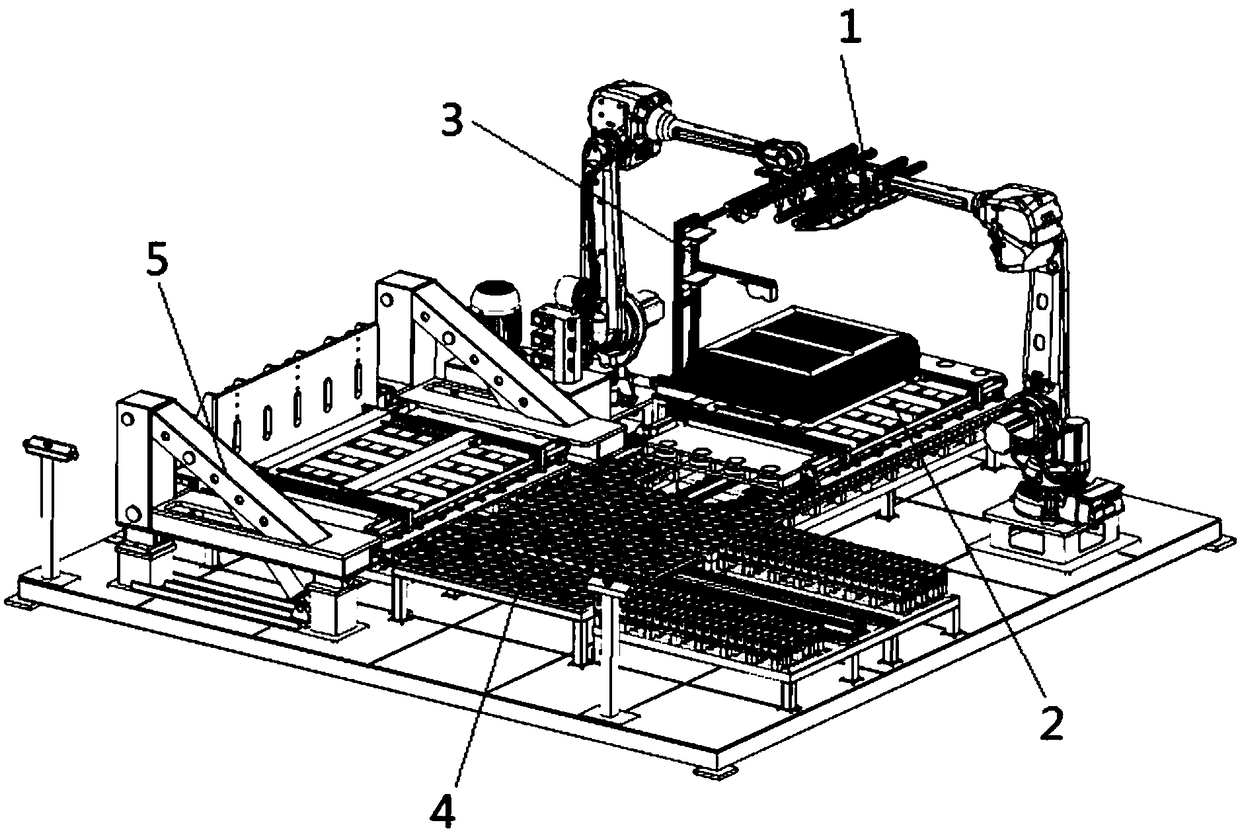

[0027] combine figure 1 , figure 2 As shown, a transformer core high-speed lamination automation system is mainly composed of an automatic lamination workstation, a cross-cutting line 6 and a safety fence 7 . The system is an automatic lamination equipment for transformer iron core silicon steel sheets, and the cross-cutting line 6 is a numerically controlled cross-cutting line, which can realize the cutting of various shapes of silicon steel sheets and the sorting of silicon steel sheets through program control. The automatic lamination workstation automatically grabs the cut silicon steel sheets on the cutting table of the cross-cutting line 6, and can automatically stack the cut silicon steel sheets into the iron core set by the system; the safety fence 7 separates the lamination area of the lamination workstation from the outside world. Separated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com