Considering wheel-rail rolling contact, the coupling modeling analysis method of high-speed railway subgrade

A high-speed railway and analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of insufficient accuracy of dynamic response finite element analysis, and achieve a reasonable and comprehensive model setting, fine structure, and improved accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

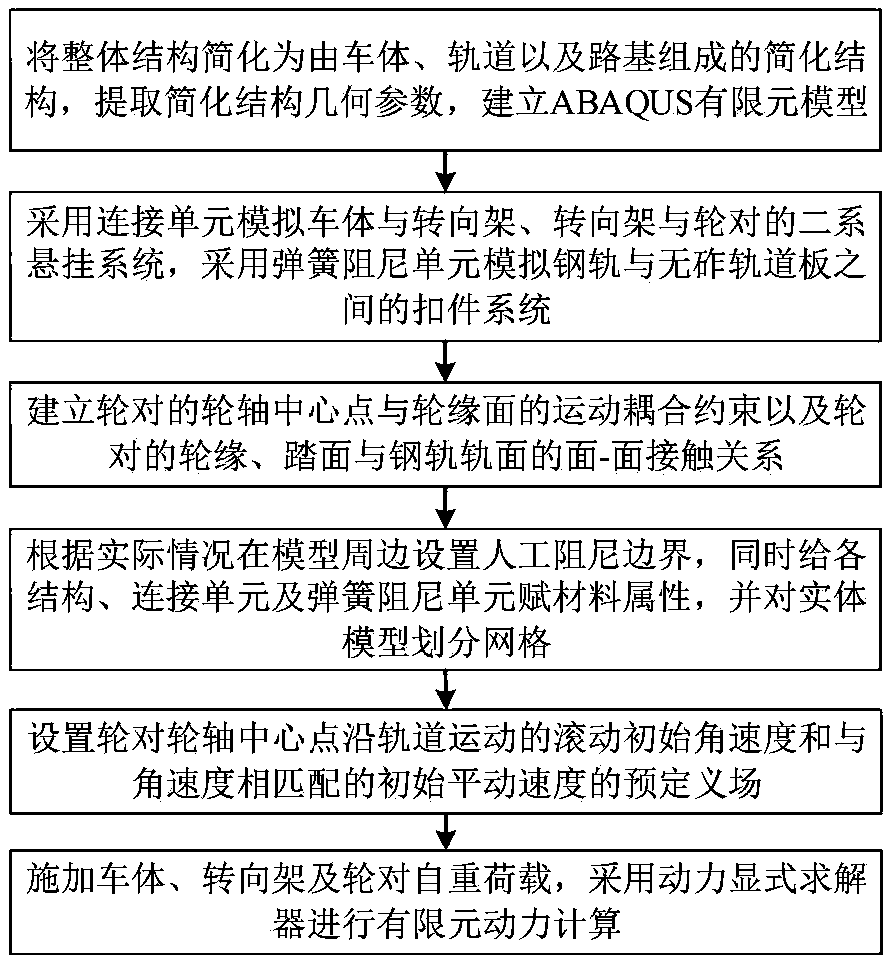

[0042] A high-speed railway subgrade coupling modeling analysis method considering wheel-rail rolling contact, such as figure 1 The flow shown, the specific steps are as follows:

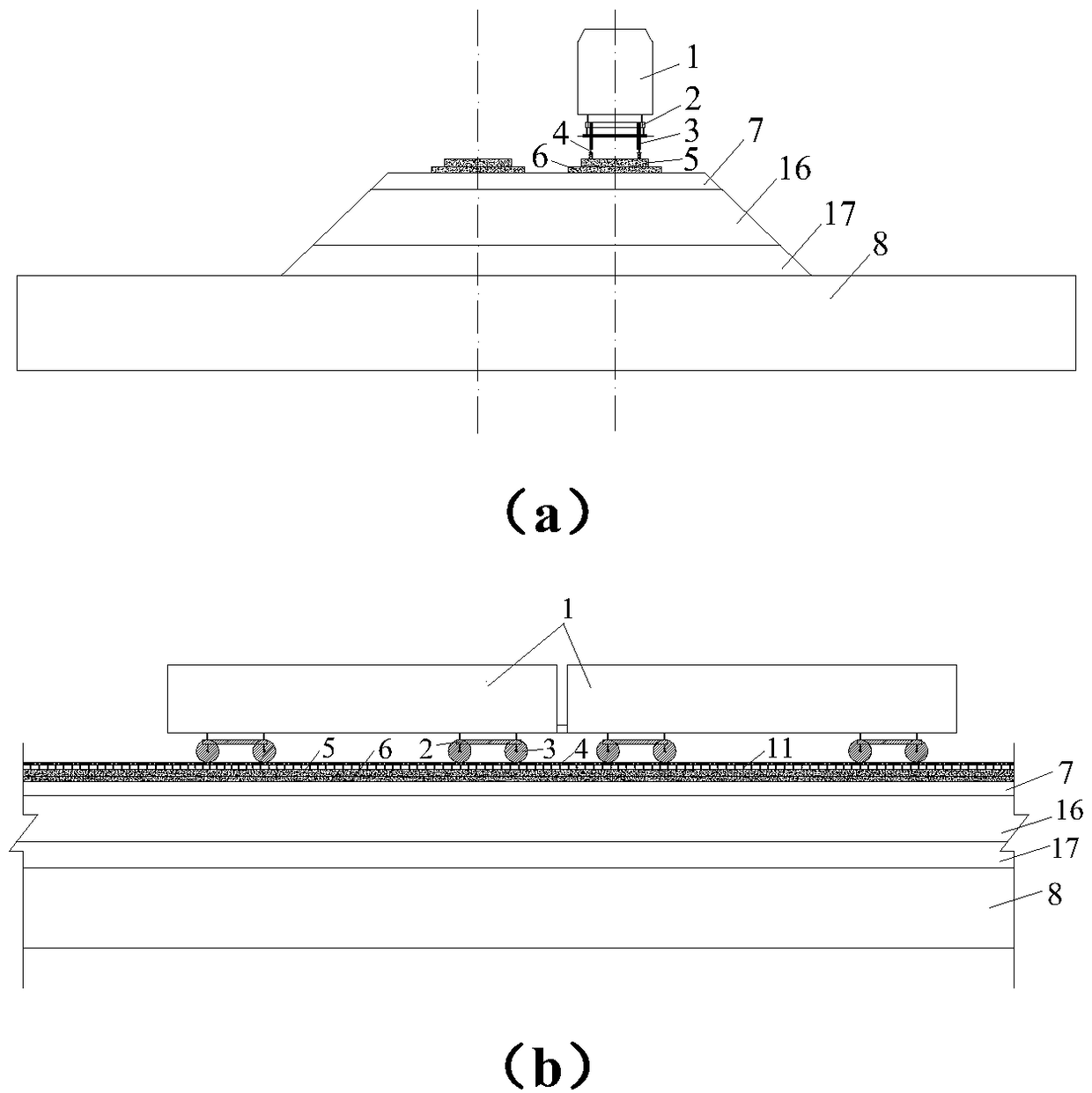

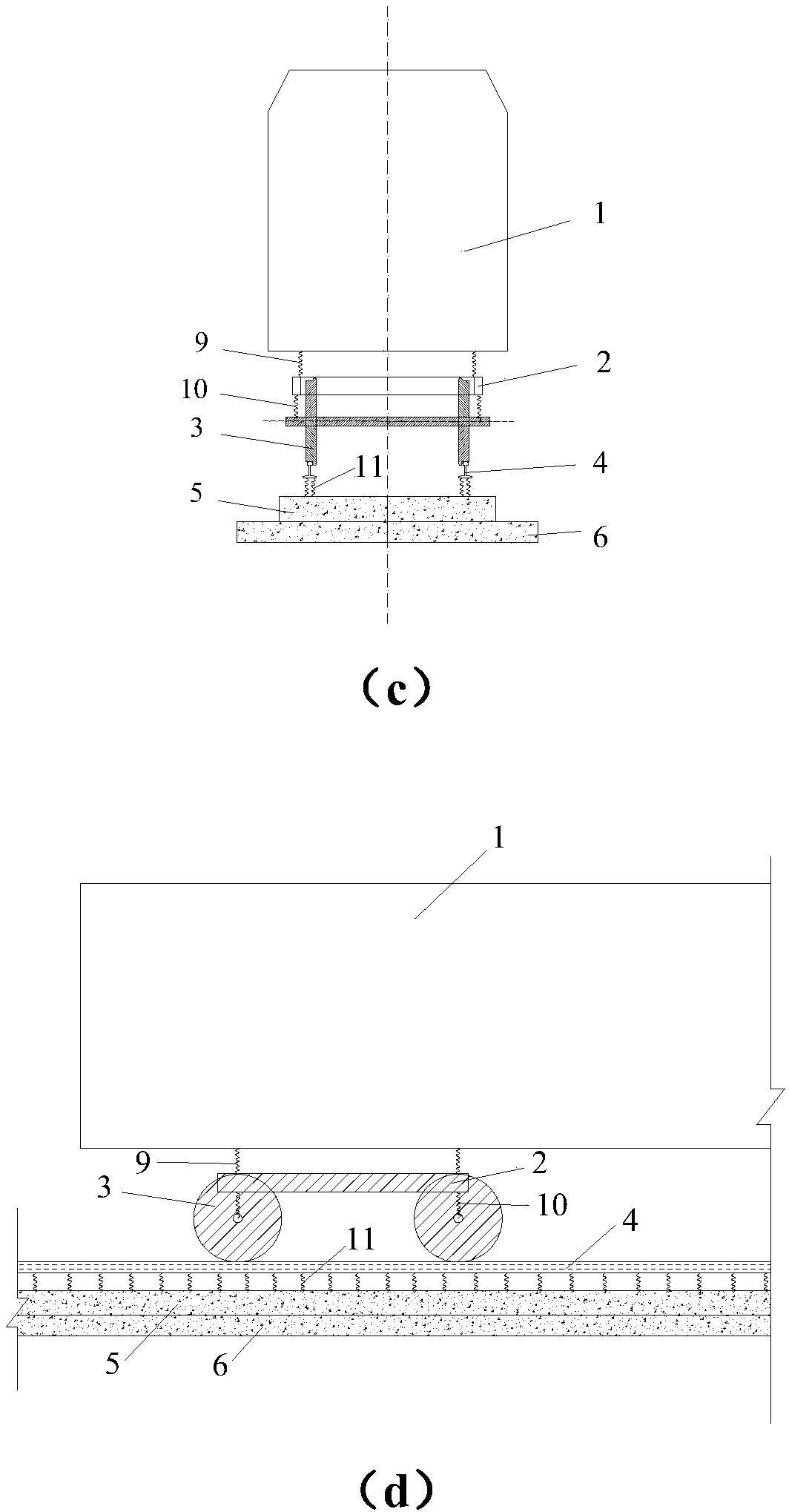

[0043] (1) Simplify the overall model structure into vehicle structure (including car body 1, bogie 2, wheel set 3), track structure (including rail 4, track plate 5) and subgrade structure (including base plate 6, surface layer of subgrade bed 7, the simplified structure of subgrade bed bottom layer 16, subgrade body 17 and foundation 8), as figure 2 as shown, figure 2 (a) is a cross-sectional view, figure 2 (b) is the longitudinal section view, figure 2 In (c) and figure 2 Middle (d) is an enlarged view of the detailed structure. Extract geometric parameters such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com