Substation inspection robot navigation method with laser positioning and radio frequency positioning

A technology of inspection robot and navigation method, which is applied in the field of electric power system and robot, can solve the problems of poor positioning accuracy and difficult track laying, and achieve the effects of high positioning accuracy, rich inspection routes, and accurate and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Example

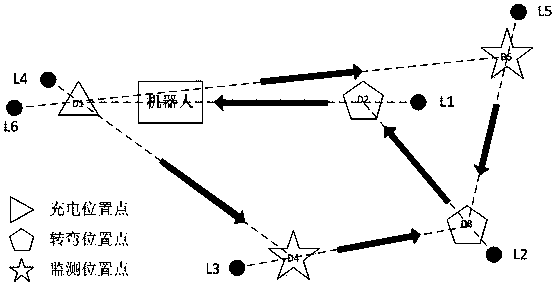

[0043] like figure 2 Shown: The substation is set with charging position point D1, turning position points D2 and D3, monitoring position points D4 and D5, and set up 6 laser light sources L1 to L6, among which monitoring position point D4 is the regular inspection position point and position point D5 For key equipment monitoring position points, each position point has a unique number and is equipped with a corresponding radio frequency card with a unique number. Position points D2, D3, D4, and D5 are set with a corresponding laser light source, and position point D1 is set with two lasers light source. When the laser light source L1 irradiates from the position point D2 to the position point D1, when the laser light source L2 irradiates from the position point D3 to the position point D2, when the laser light source L3 irradiates from the position point D4 to the position point D3, when the laser light source L4 irradiates from the position point D3 D1 po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com