Beveled foam and production method thereof

A foam and oblique cutting technology, applied in the field of foam glue, can solve problems such as the interference of the lower edge of the display window of the calculator, and the easy misinstallation of the front and back of the foam glue, and achieve simple and reasonable production methods, good shock absorption effect, Good punching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

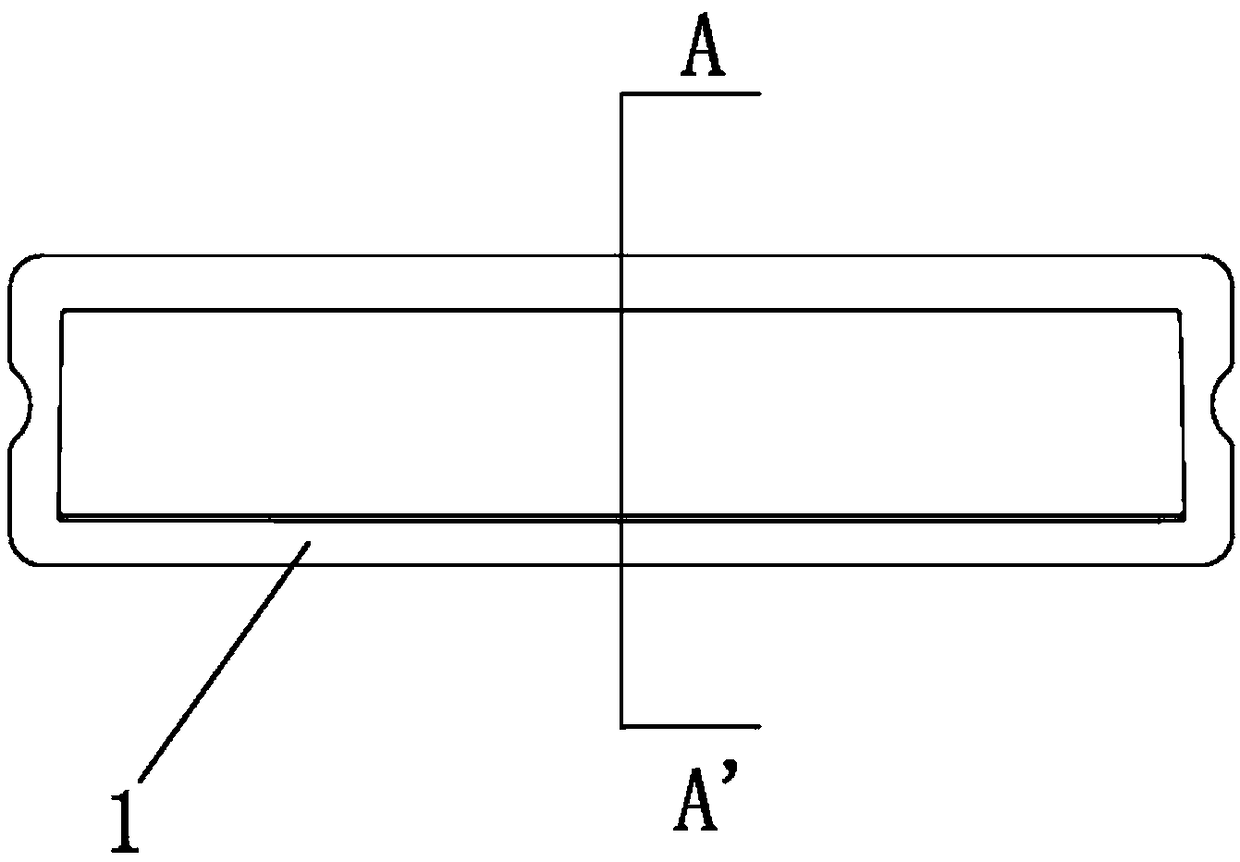

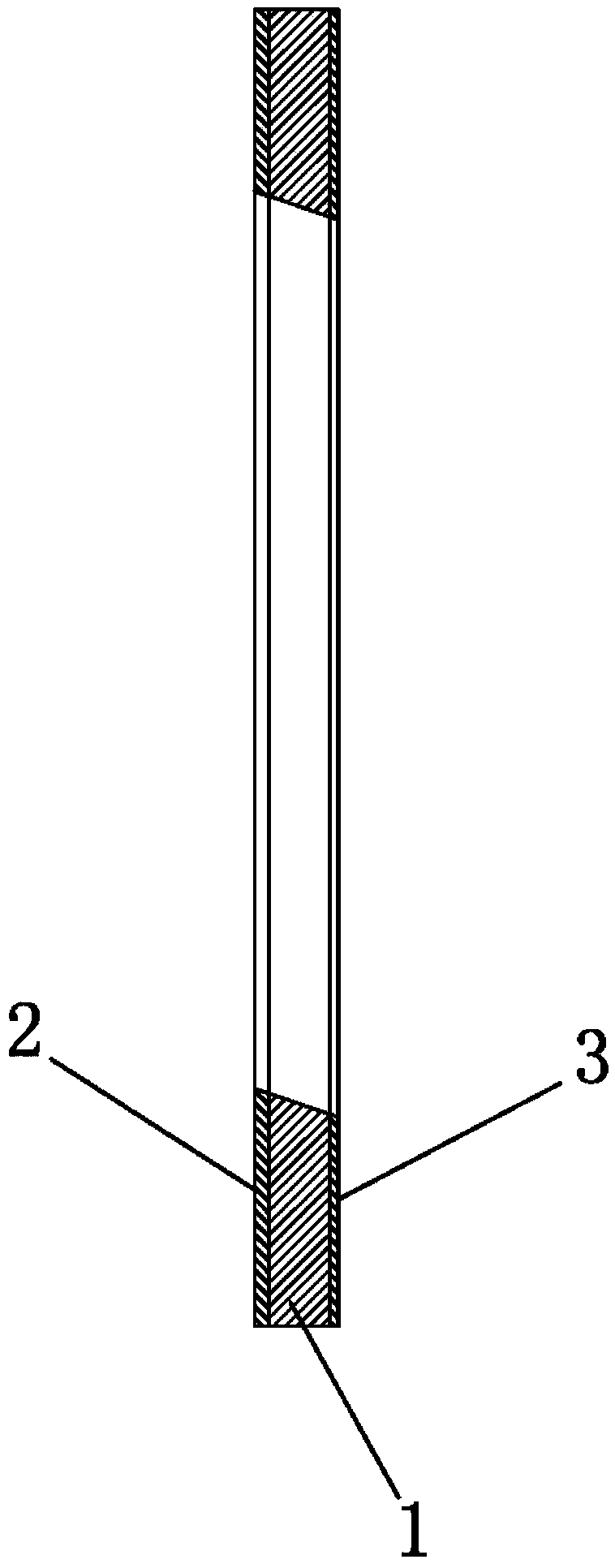

[0023] combine figure 1 , figure 2 , the invention discloses a beveled foam, comprising a foam body 1 . The thickness of the foam body 1 may be 0.8-2mm. The foam body 1 has a sheet-shaped rectangular frame structure, and hollowed-out rectangular windows are arranged inside. The short end surfaces on both sides of the rectangular window hole are parallel to the thickness direction of the foam body 1 . The long side end faces on both sides of the rectangular window hole are parallel to each other, and there is an inclination angle with the thickness direction of the foam body 1 . Preferably, the included angle between the long side end surface of the rectangular window hole and the thickness direction of the foam body 1 is 15-25°. Preferably, the included angle between the long side end surface of the rectangular window hole and the thickness direction of the foam body 1 is 19°. A first adhesive layer 2 and a second adhesive layer 3 are laminated on both sides of the foam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com