Yarn arranging system capable of being easily operated

A kind of yarn, simple technology, applied in the field of yarn finishing system, can solve the problems of lack of counting function, error-prone memory, insufficient flexibility, etc., and achieve good effect of connection and power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

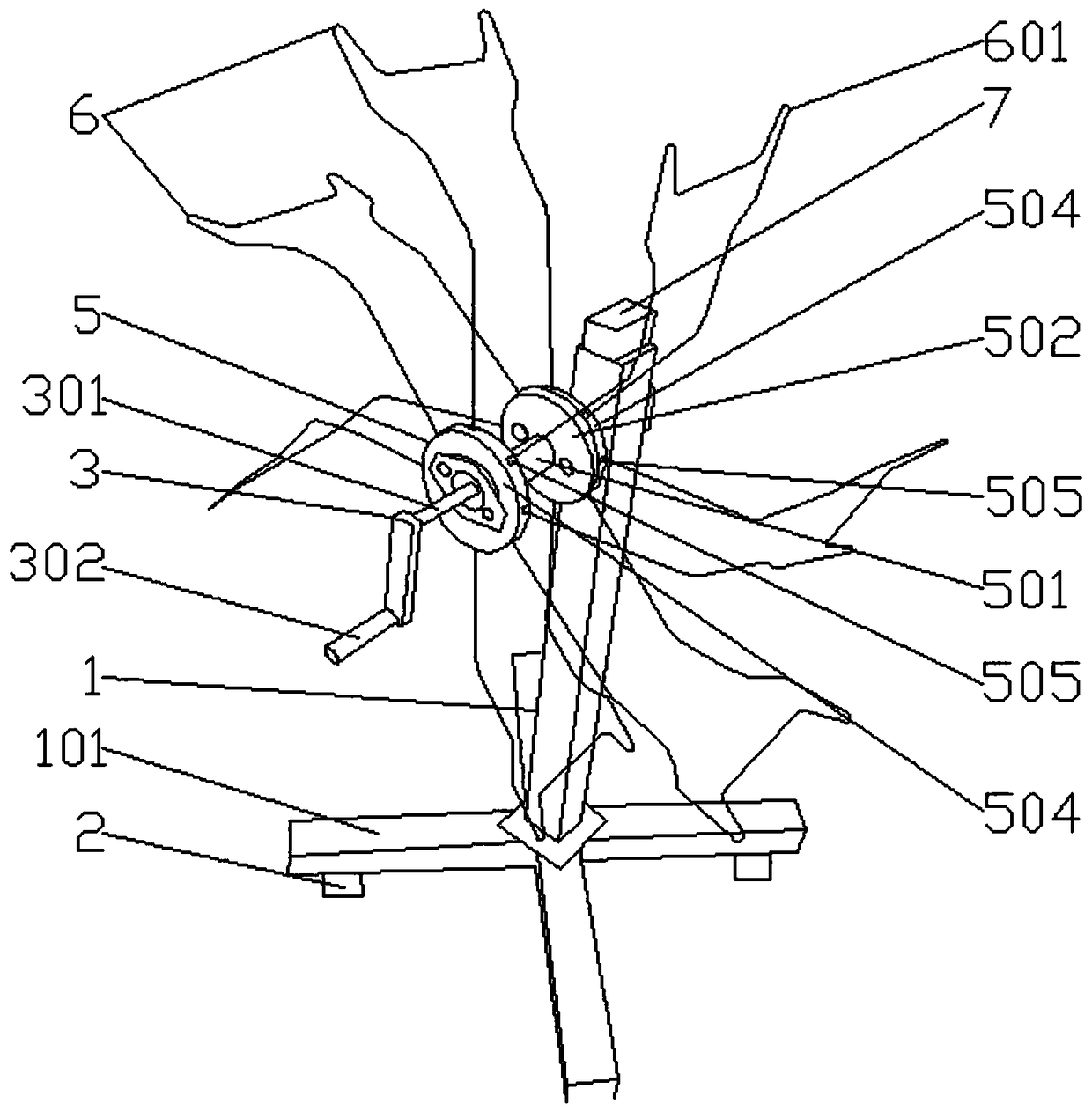

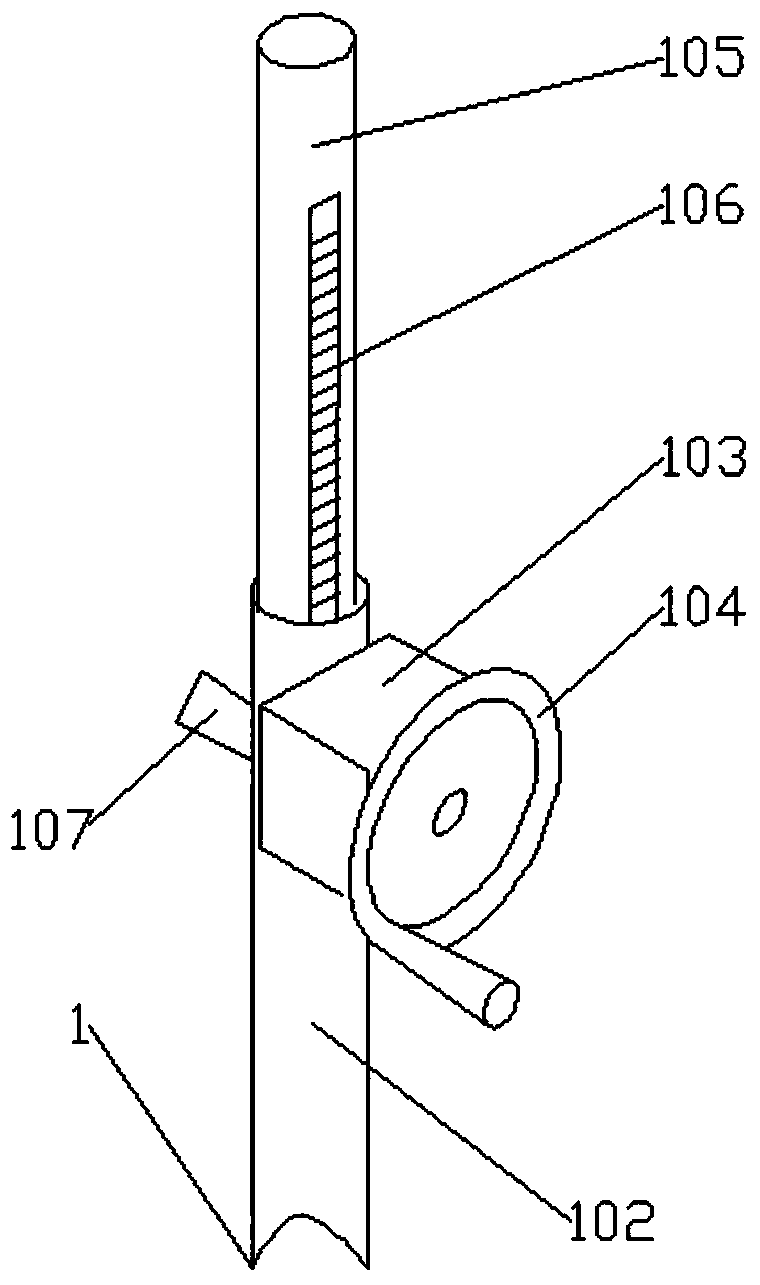

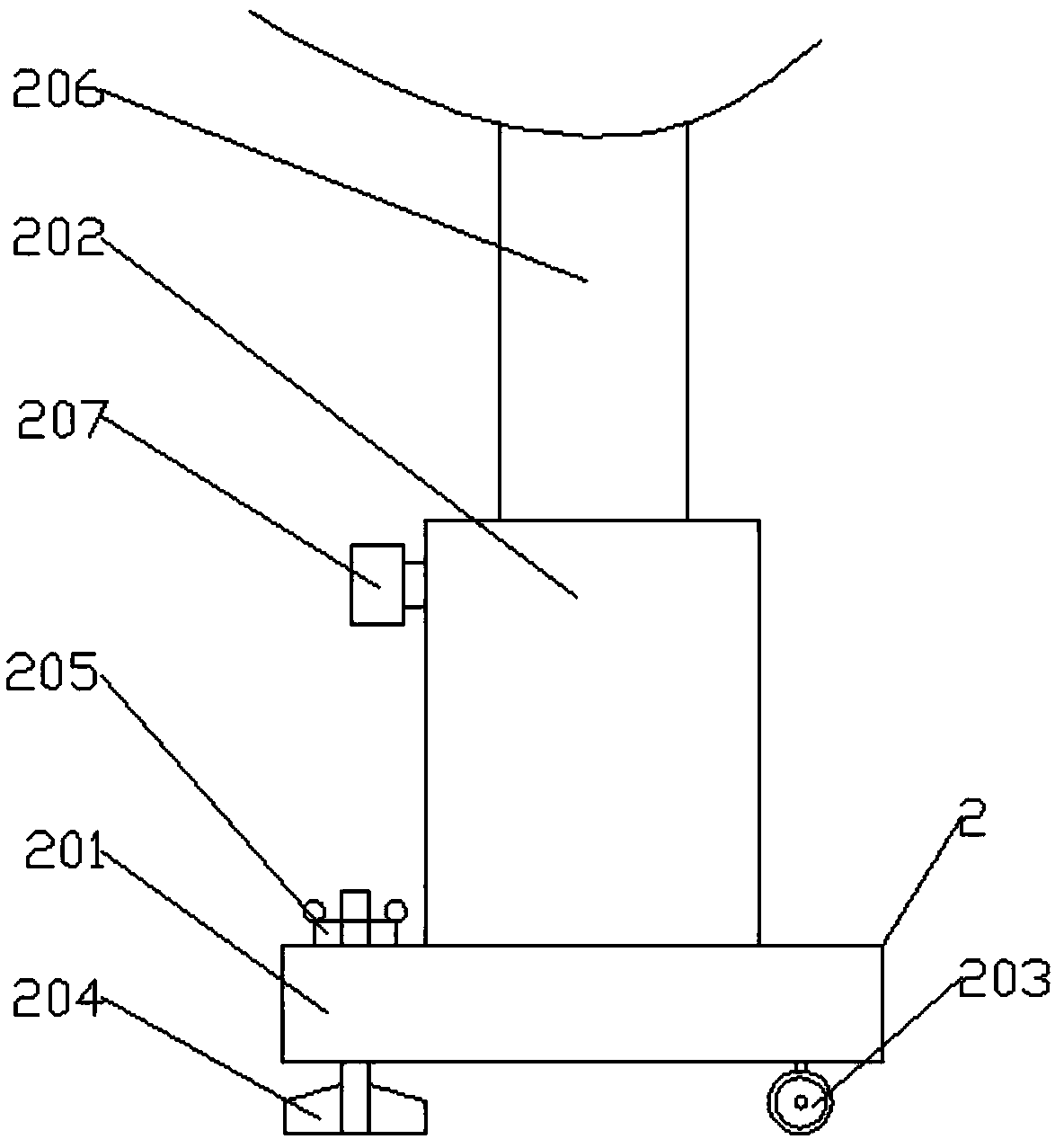

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 , Picture 11 , Picture 12 , Figure 13 , Figure 14 with Figure 15 The simple-to-operate yarn finishing system shown includes a lifting bracket 1, a number of supporting mechanisms arranged at the bottom of the lifting bracket 2, a rotating mechanism 3 rotatably arranged on the upper part of the lifting bracket, a connecting piece 4 arranged on the rotating mechanism, and The roulette assembly 5 on the rotating mechanism, several scaffold assemblies 6 arranged on the roulette assembly, and a mechanical counting mechanism 7 arranged on the top of the lifting bracket, the connecting piece is connected with the mechanical counting mechanism; the lifting bracket includes a base 101 and a mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com