Energy-feedback suspension system

A suspension system and energy-feeding technology, which is applied in the field of energy-feeding suspension systems, can solve the problems that the energy-feeding suspension cannot efficiently recover vibration energy and the performance of individual certificates is not good, so as to improve the handling stability and driving comfort, The effect of improving comprehensive performance and excellent vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

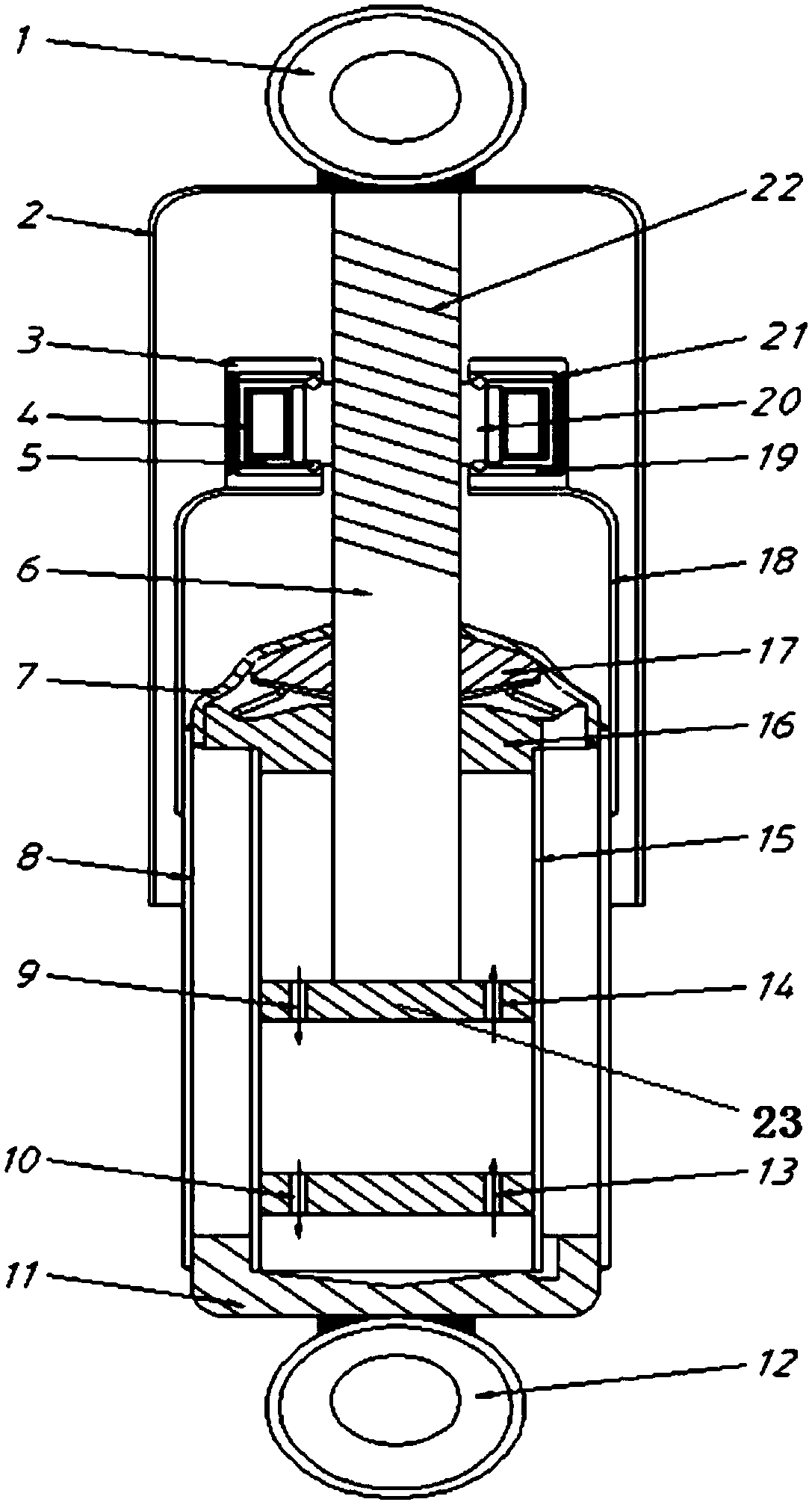

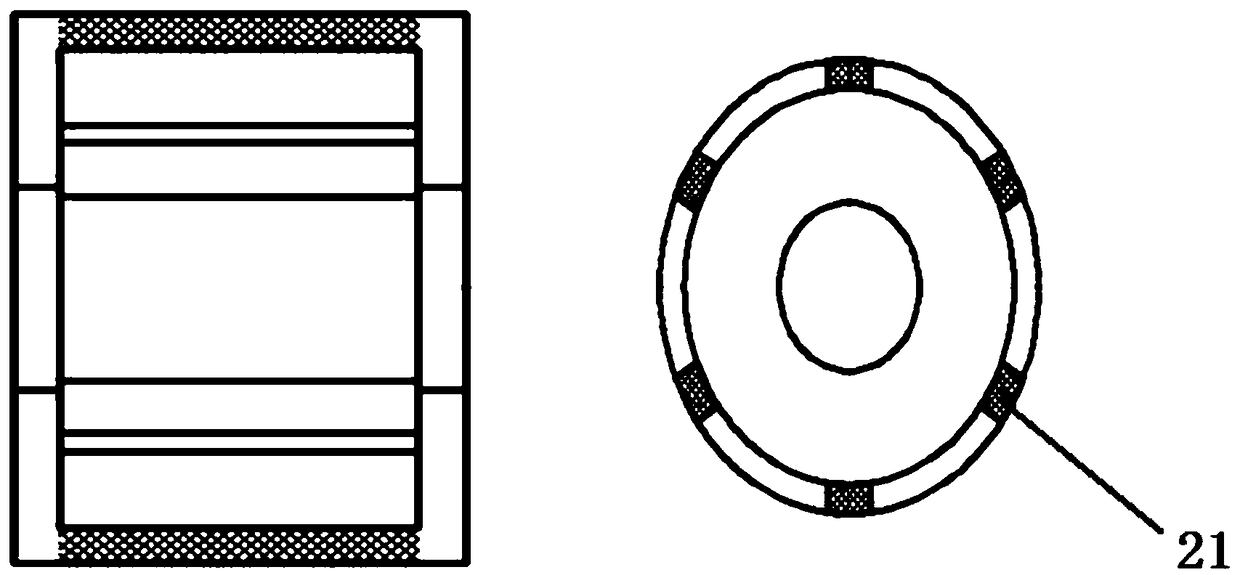

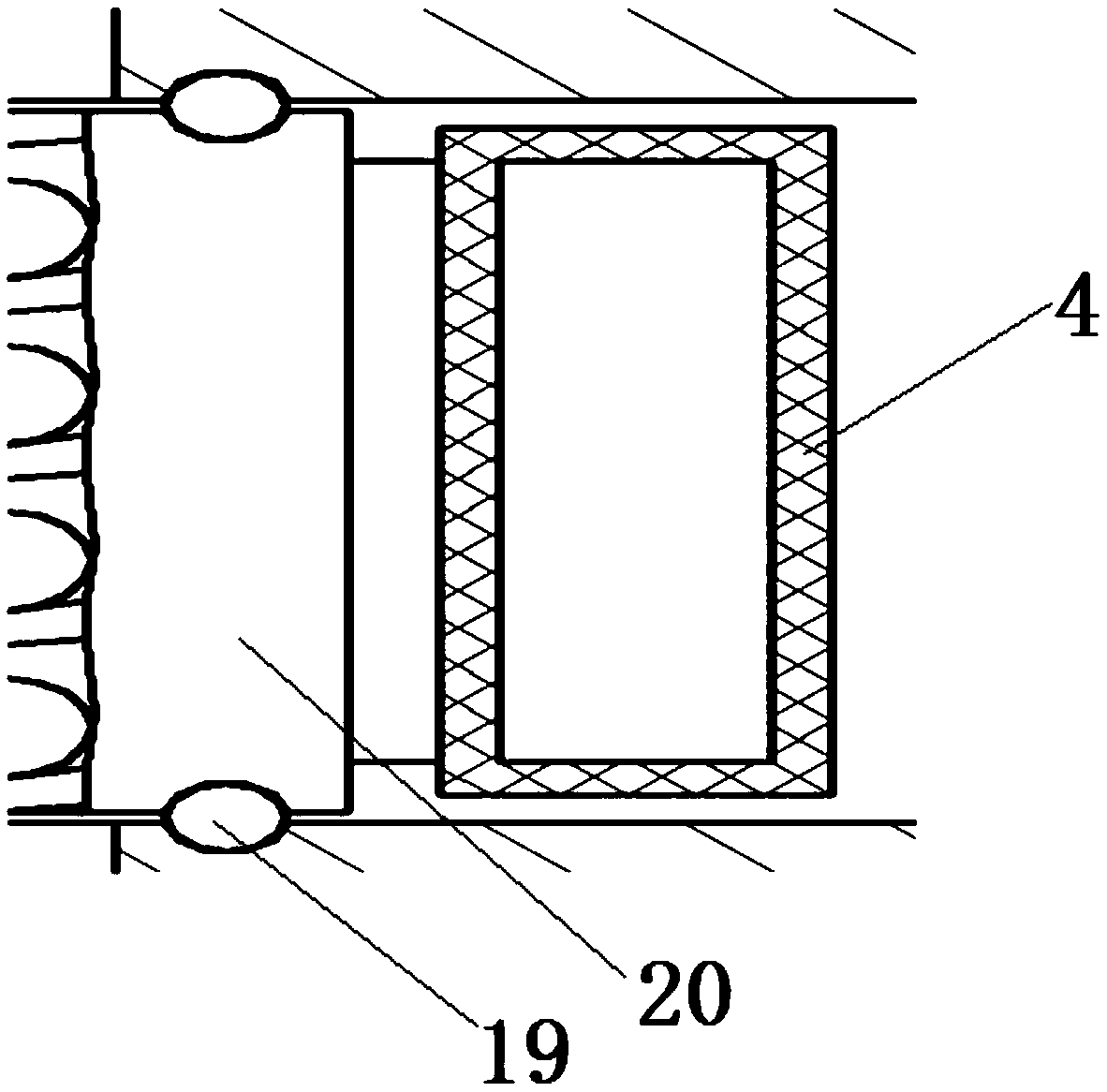

[0023] Specific implementation mode one: see Figure 1-Figure 4 This embodiment will be described. The energy-feeding suspension system described in this embodiment includes an upper suspension ring 1, a dust cover 2, a permanent magnet frame 3, a coil winding 4, a piston rod 6, a piston 23, a sealing cover 7, an oil storage barrel 8, an extension valve 9, Compression valve 10, bottom cover 11, lower lifting ring 12, compensation valve 13, flow valve 14, working cylinder 15, guide 16, oil seal 17, bracket cylinder 18, stopper 19, lead screw nut 20, permanent magnet 21 and ball Lead screw 22; the top of the dust cover 2 is equipped with an upper ring 1, the axial middle position in the dust cover 2 is equipped with a piston rod 6, and the top of the piston rod 6 is set as a screw structure 22, The outer periphery of the screw structure 22 is covered with a lead screw nut 20, the upper and lower ends of the lead screw nut 20 are equipped with stoppers 19, the outer periphery of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com