Material tray tilting mechanism and DLP technology 3D printing device

A technology of tilting mechanism and tray, applied in the field of 3D printing, can solve the problem of broken products or trays, and achieve the effect of prolonging the service life, improving the qualification rate of products, and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

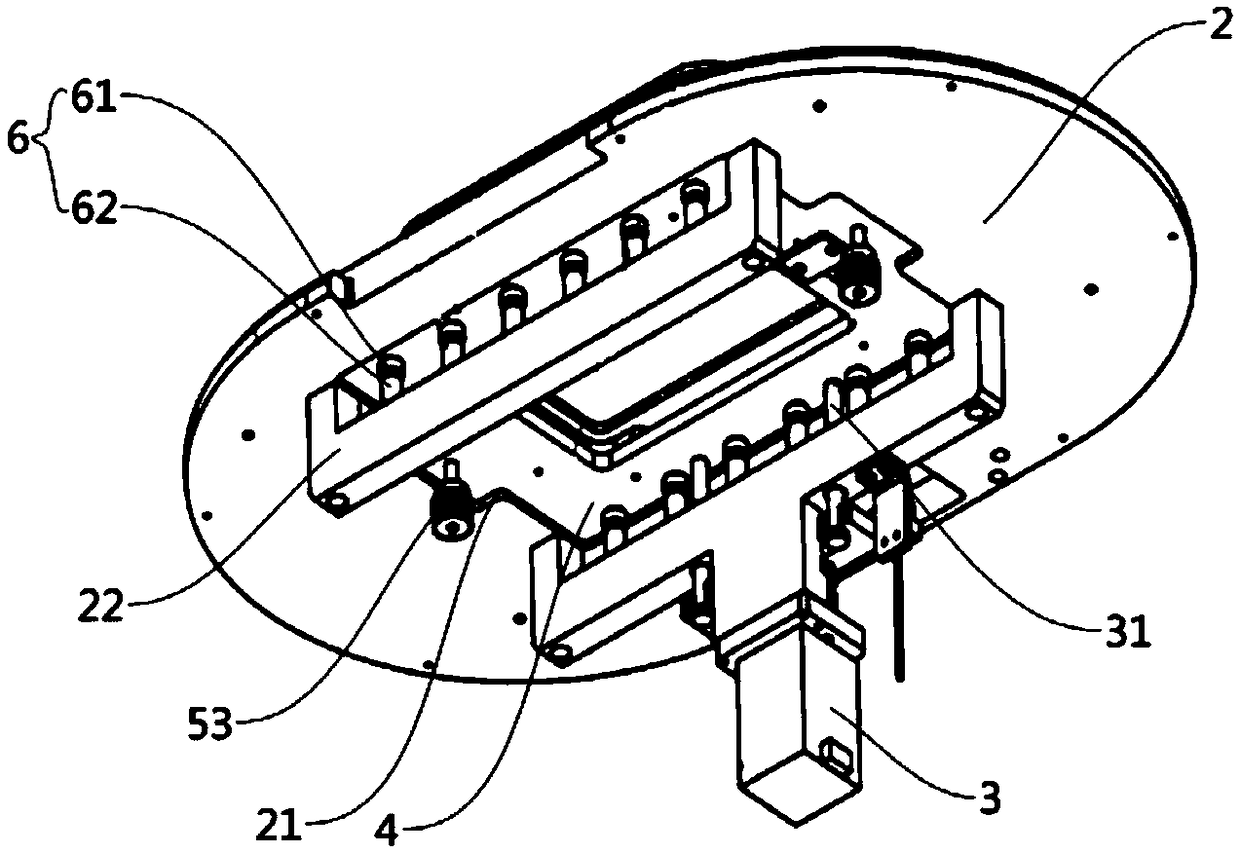

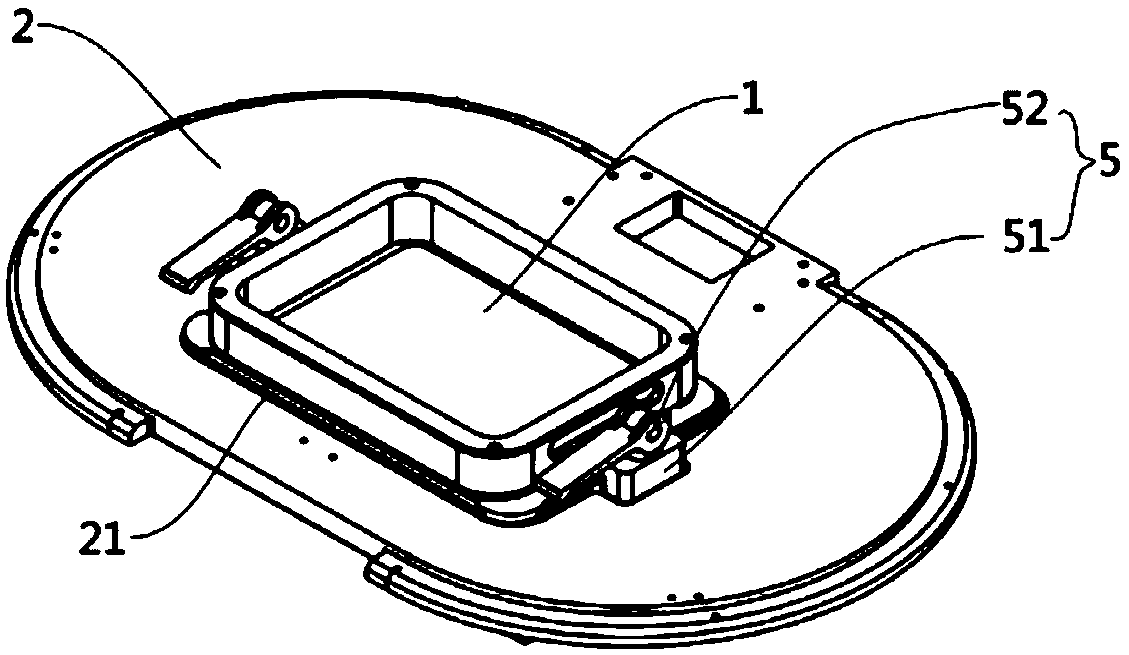

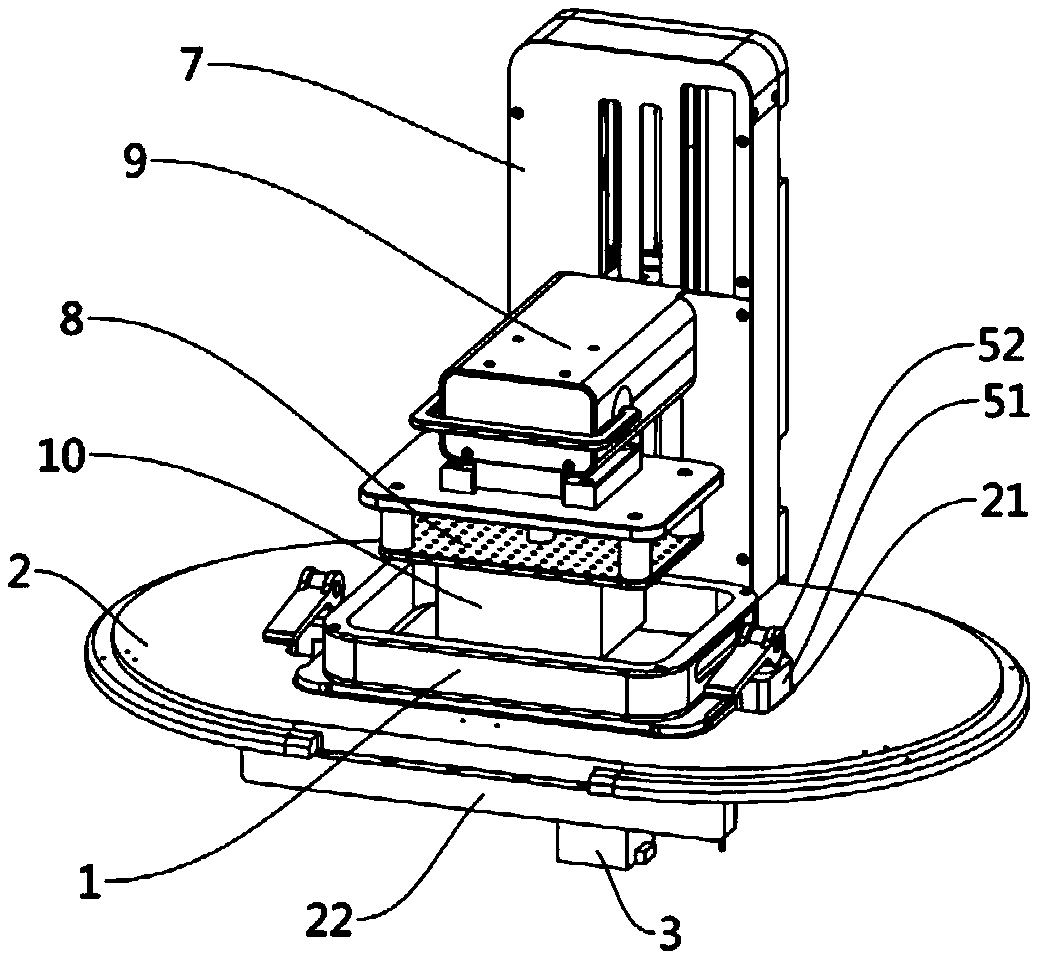

[0057] See figure 1 , figure 2 , a material tray tilting mechanism, including a material tray mounting plate 2 and a driving device 3, the material tray mounting plate 2 is provided with a connecting bracket 22 and a through hole 21, and the driving device 3 is provided on the connecting bracket 22, and is used for driving the material tray 1 moves up and down one side or one corner of the through hole 21 .

[0058] Therefore, when the material tray tilting mechanism is applied to the DLP technology 3D printing device, when the product and the material tray need to be peeled off, before the forming platform lifting mechanism drives the forming platform to move vertically upward, it can be driven by the material tray tilting mechanism. One side or one corner of the tray moves down a certain distance, even if the tray is inclined, the peeling force acting on the tray is uneven, and the peeling force on the part directly driven by the driving device is larger, so that one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com