Mixer truck rotary sealing device with non-fixed rotary shaft

A technology for rotary seals and mixer trucks, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc. It can solve the problems of vulnerable parts, poor sealing effect, and high maintenance costs, so as to reduce wear, reduce weight, The effect of reducing workload and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

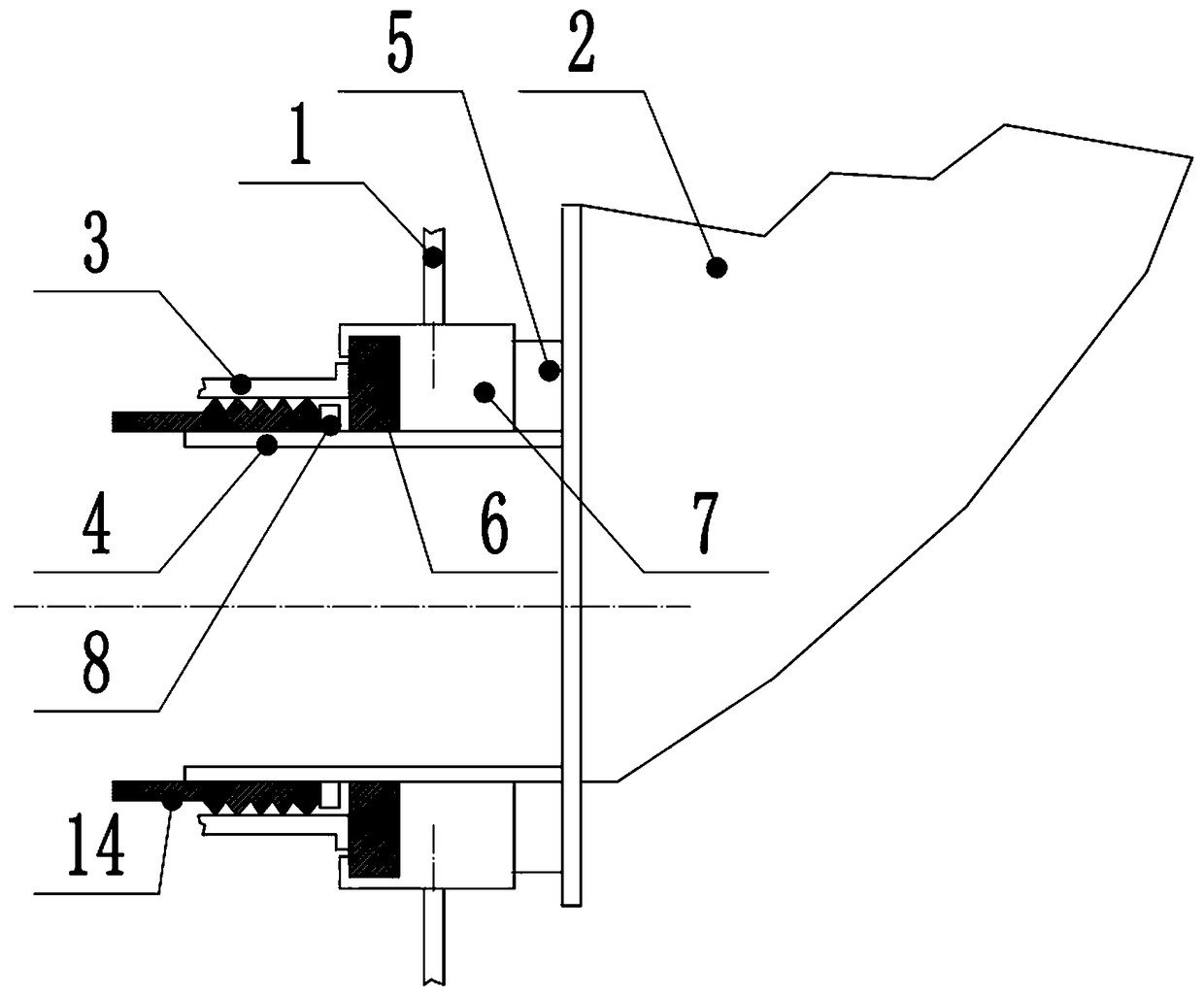

[0030] like figure 1 , a rotary sealing device for a mixer truck with a non-fixed rotary shaft, the mixer truck includes a mixing bucket installed on the vehicle body and capable of rotating relative to the vehicle body, and a moving part installed on the vehicle body and capable of moving relative to the vehicle body 11. There is a rotary sealing cover 1, the outer edge of the rotary sealing cover 1 is in contact with the outer edge of the outlet of the mixing tank, and the contact is provided with a sealing outer ring, so that the rotary sealing cover 1 is driven by the mixing tank with stirring The barrel rotates relative to the moving part 11; a through hole is opened in the middle part of the rotating sealing cover 1; a feeding hopper 2 is installed on the moving part 11, and the outlet of the feeding hopper 2 is connected with a The cover 1 is through the hole and extends into the feeding cylinder 4 of the mixing bucket.

[0031] The rotary seal cover 1 includes a suppo...

Embodiment 2

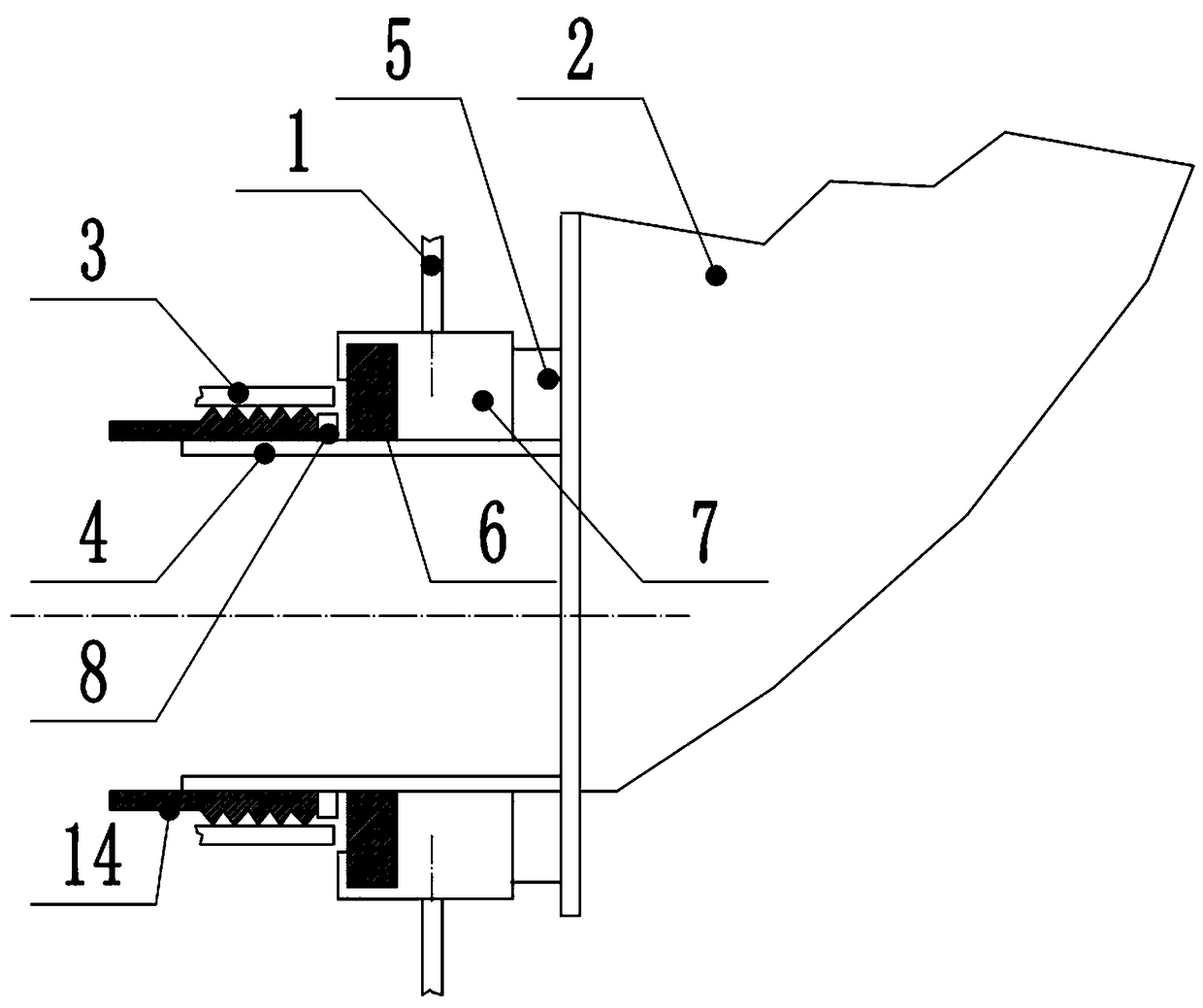

[0042] like figure 2 The difference between this embodiment and the first embodiment is that there is a gap between the rear end of the central barrel 3 or the front end surface of the sealing inner ring 6 .

Embodiment 3

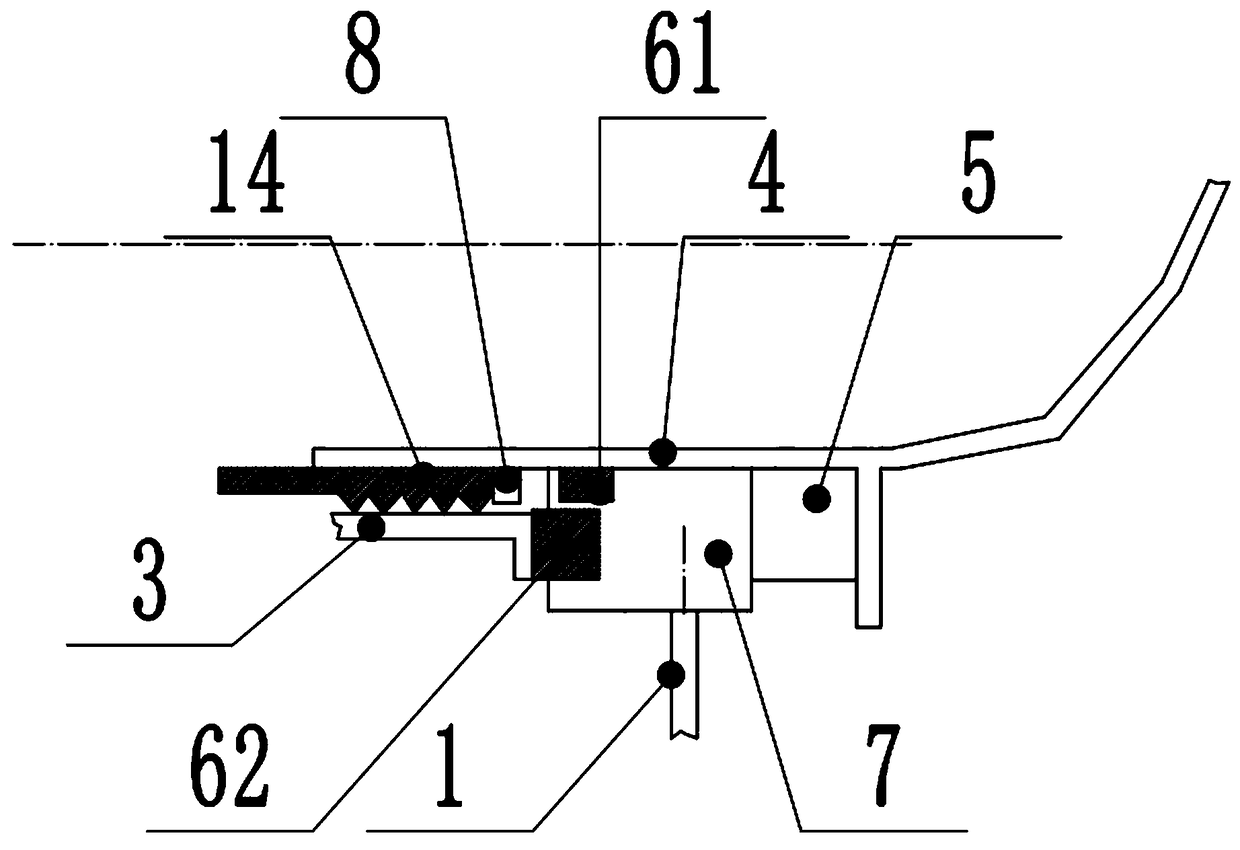

[0044] like image 3 The difference between this embodiment and Embodiment 1 is that the sealing mechanism is not an integral sealing inner ring 6, but a split structure, including a circumferential sealing ring 61 and an end face sealing ring 62, and the inner sealing ring 61 of the circumferential sealing ring The hole is in contact with the outer wall of the feeding barrel 4 , and the rear end of the central barrel 3 is in contact with the front end of the end face sealing ring 62 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com