Electric displacement setting-out device and lofting method of heteromorphic spiral body intersecting line

A technology of electric displacement and helix, which is applied in the direction of workshop equipment and manufacturing tools, can solve the problems of inaccurate positioning and affecting installation accuracy, and achieve the effect of ensuring the accuracy of lofting, reducing construction costs, and reducing labor difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

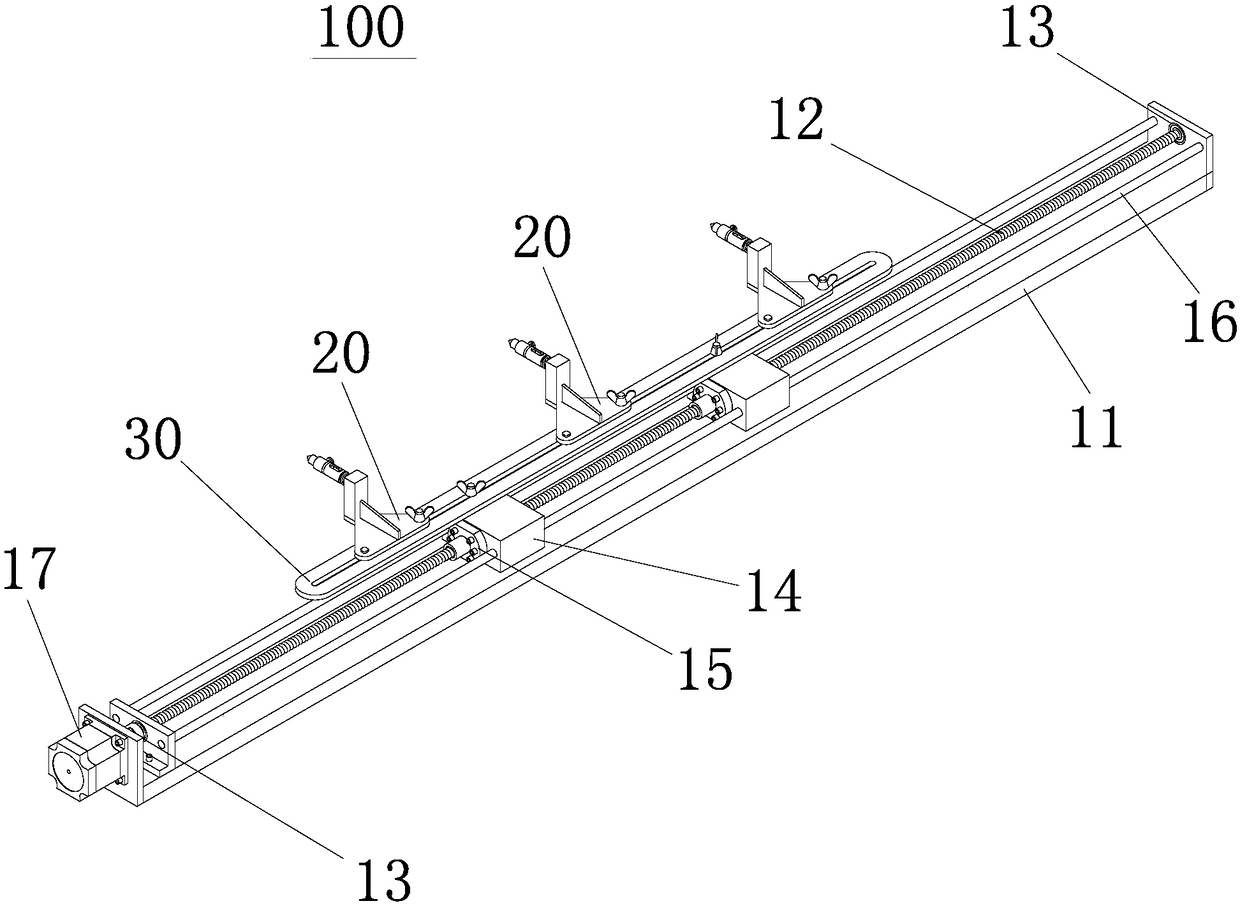

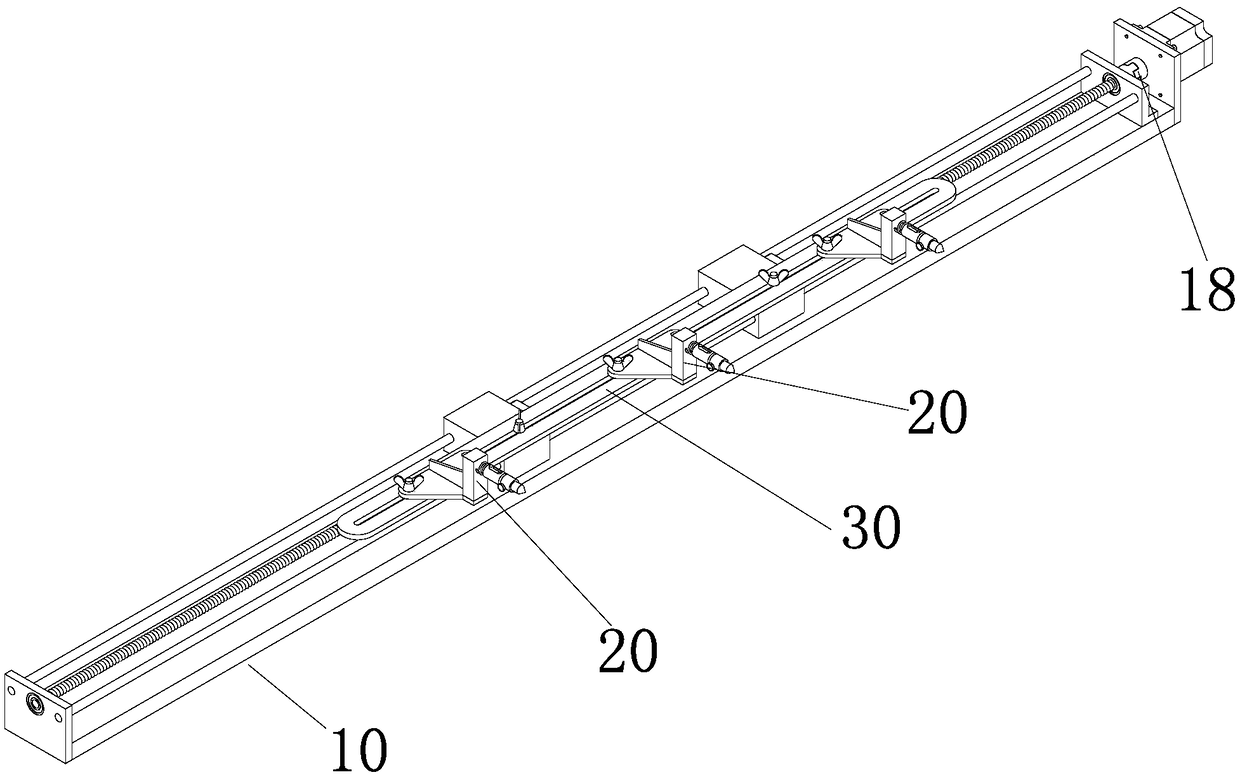

[0040] Such as Figure 1-4 As shown, it is an electric displacement line drawing device 100 according to a preferred embodiment of the present invention, which includes a screw slide 10 and at least one line drawing mechanism 20 installed on the screw slide 10. The screw slide 10 according to the displacement information With the drawing line mechanism 20 moves the drawing line. The line-drawing mechanism 20 is an adaptive adjustment structure, including a base plate 21, a bracket 22, a fixed rod 23, a rod cover 24, a spring 26, and a nib 29. One end of the base plate 21 is vertically mounted with a bracket 22, and the upper end of the bracket 22 is horizontally mounted with a cylinder. fixed rod 23, the fixed rod 23 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com