Method for controlling quality of cold-rolled silicon steel casting blank

A cold-rolled silicon steel and billet technology, which is applied in the field of quality control of cold-rolled silicon steel billet, can solve the problems of increased difficulty in production control, increased auxiliary equipment, and long production cycle, so as to promote the formation of equiaxed crystals and improve the crystal structure , reduce the effect of shrinkage of the heart

Active Publication Date: 2019-02-22

ANGANG STEEL CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the production of modern non-oriented electrical steel, with the increase of grades, it is required to increase the content of main alloy elements and the cleanliness of the steel, and to use electromagnetic stirring devices to control the internal quality of the slab, the difficulty of production control is increased, and the auxiliary equipment is increased. The production cycle is long and the cost is greatly increased

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0034] (1) Element composition list, wt%

[0035] Example

Si

Al

S

N

Ni+V+Ti

1

2.91

0.56

0.0070

0.0025

0.0120

2

1.78

0.72

0.0056

0.0022

0.0100

2

2.45

0.57

0.0066

0.0022

0.0090

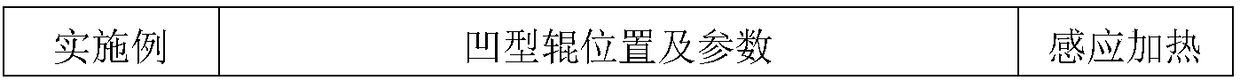

[0036] (2) Process (slab thickness 230mm)

[0037]

[0038]

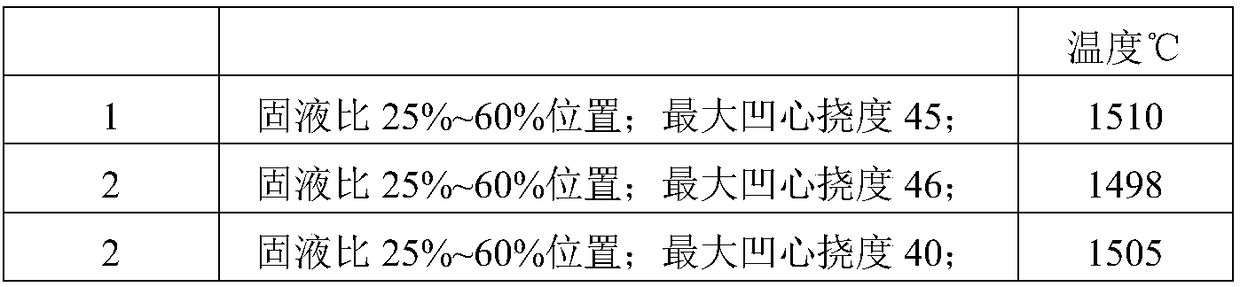

[0039] (3) Effect:

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for controlling quality of a cold-rolled silicon steel casting blank. The content of harmful elements of silicon steel is that the content of sulfur is less than or equal to 0.0080%, the content of nitrogen is less than or equal to 0. 0030%, and the total content of niobium plus vanadium plus titanium easy-to-form carbon nitride elements is less than or equal to 0.0150%; in the solidification process of a continuous cast silicon steel sheet blank in the secondary cooling zone, in the metallurgical length range with the solid-liquid ratio ranging from 25% to 60%,a concave cooling roller is adopted; after the convex sheet blank is formed, an induction heating device is additionally arranged; and a flat roller cooling roller is adopted to eliminate the convexity of the sheet blank, namely "bulging". On the basis that the overall production process of enterprise high-grade electrical steel is not changed, the control difficulty of the steel cleanliness is reduced; through the change and control of the continuous casting cooling process, a similar casting blank light-pressing mode is combined, the original crystal orientation structure of columnar crystals is reserved, but the abnormal development of the casting blank columnar crystals is inhibited; and harmful products such as inclusions can be promoted to float up and can be prevented from segregating in the center line, and thus the quality of the casting blank can be improved.

Description

technical field [0001] The invention relates to the technical field of steel rolling, in particular to a method for controlling the quality of cold-rolled silicon steel slabs. Background technique [0002] Electrical steel products are widely used metal functional soft magnetic materials, mainly used in the field of iron core manufacturing of various motors and electrical appliances. With the improvement of automation in all walks of life and the development of high-efficiency motors, the demand for high-efficiency electromagnetic properties with excellent surface quality has become the development trend of high-grade electrical steel products. [0003] In the production of modern non-oriented electrical steel, with the increase of grades, it is required to increase the content of main alloy elements and the cleanliness of the steel, and to use electromagnetic stirring devices to control the internal quality of the slab, increasing the difficulty of production control, incre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21B1/02

CPCB21B1/026B21B2001/028

Inventor 高振宇孟劲松陈春梅刘文鹏张智义王洪涛李亚东张仁波周旭赵健

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com