Dust extraction devices for glass breaking machines and glass breaking machines

A technology of dust collection device and dust collection mechanism, which is applied in the direction of glass cutting device, glass production, glass manufacturing equipment, etc. It can solve the problems of affecting the quality of glass substrates, reducing the production efficiency of glass substrates, and polluting glass, so as to avoid polluting glass and The effects of surrounding environment, improving quality and production efficiency, flexible erection and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

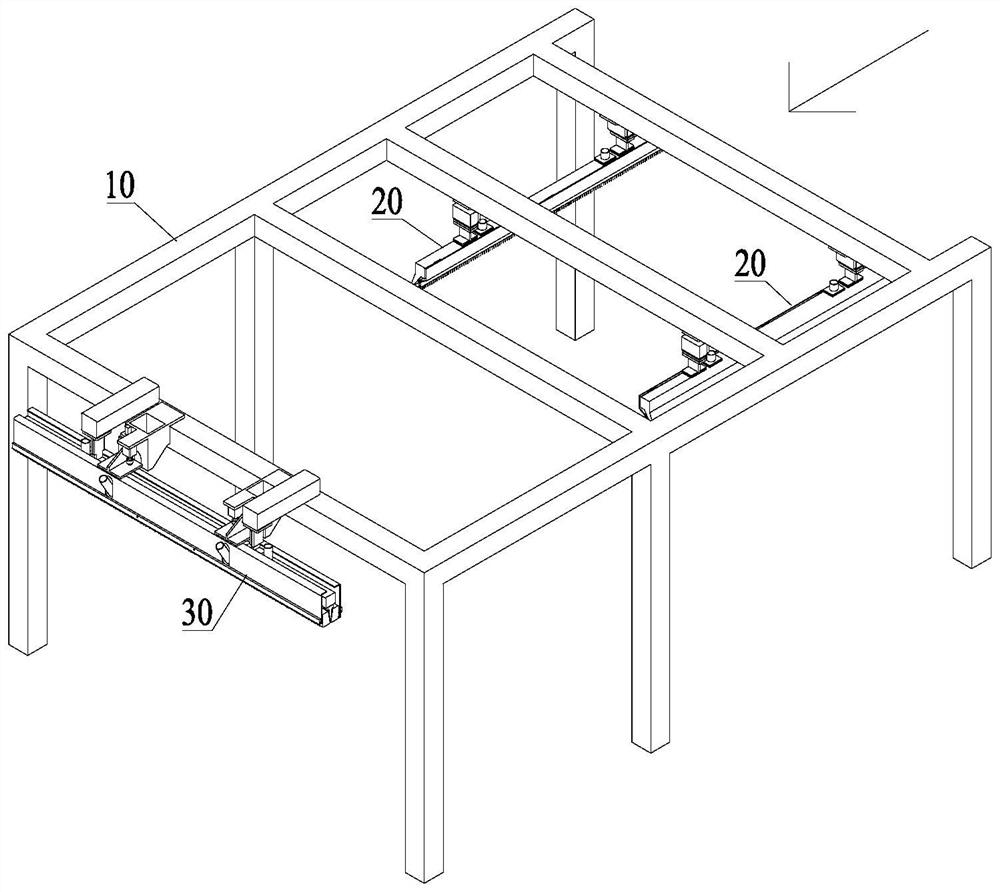

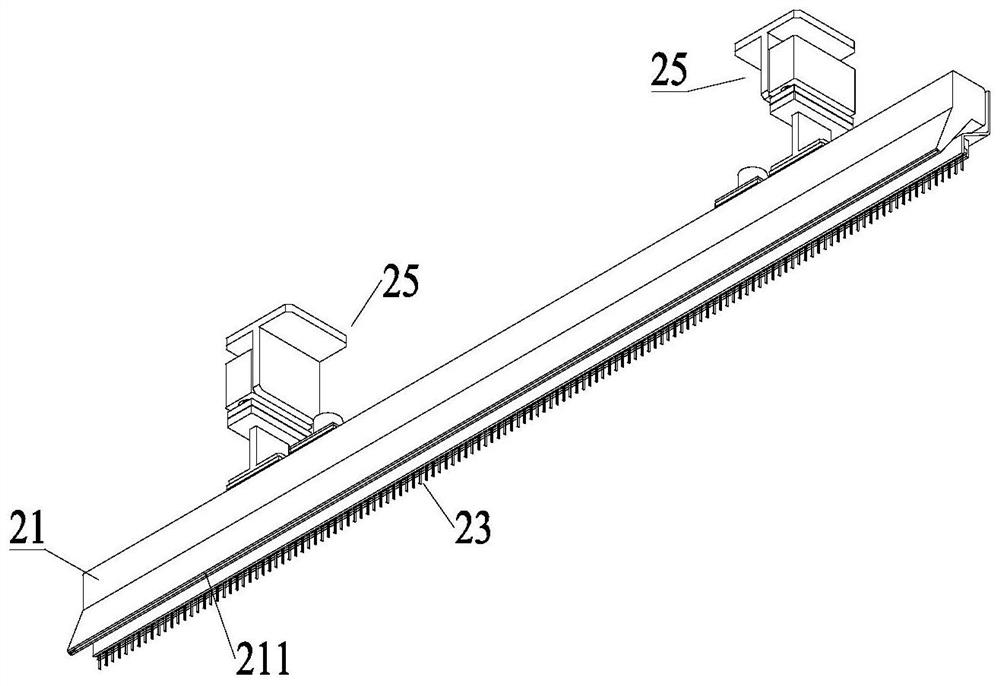

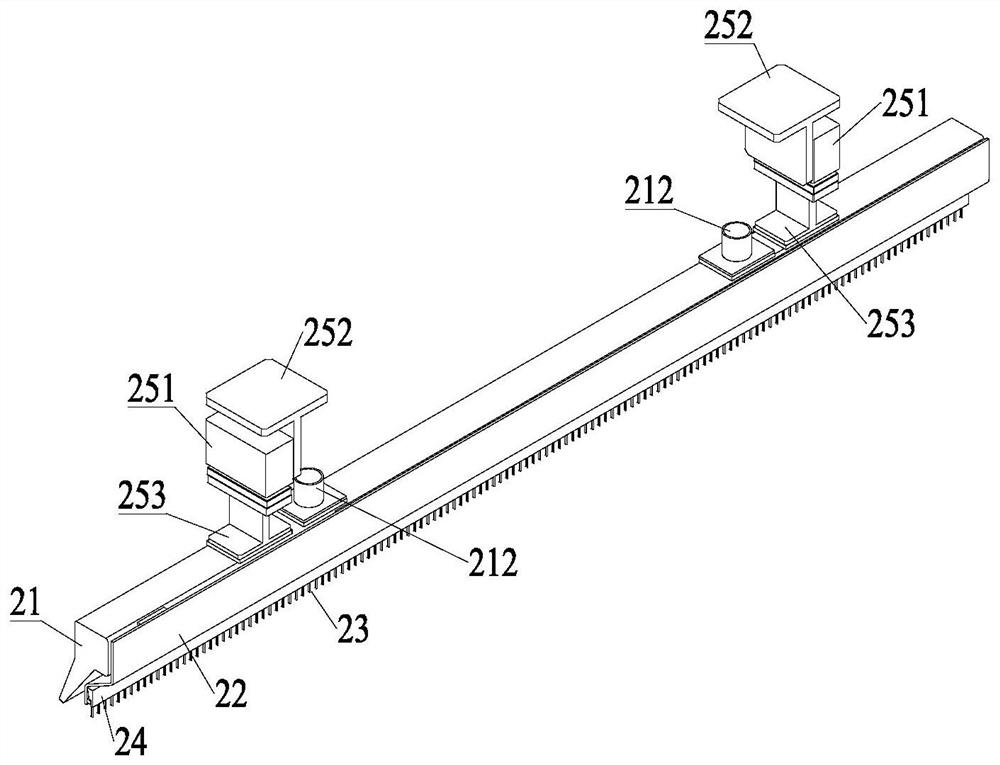

[0037] Wherein, according to an embodiment of the present invention, the longitudinal dust suction mechanism 20 includes a vertical dust suction knife 21 extending along the length direction of the glass, and the horizontal dust suction mechanism 30 includes a vertical dust suction knife 21 extending along the width direction of the glass The horizontal vacuum knife 31 of.

[0038] In order to improve the dust collection effect of the horizontal dust suction knife 31 and the vertical dust suction knife 21, specifically, according to an embodiment of the present invention, as figure 2 As shown, the longitudinal dust suction knife 21 defines a longitudinal dust suction chamber, and the bottom of the longitudinal dust suction knife 21 is provided with a longitudinal dust suction port 211 extending along the length direction of the longitudinal dust suction knife 21. The longitudinal dust suction port 211 communicates with the longitudinal dust suction chamber, and the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com