Power meter detection method based on fusion of inspection robot positioning information

An inspection robot and positioning information technology, which is applied to instruments, calculations, inspection time patrols, etc., can solve the problems of target scale, large angle change, inaccurate detection, and the target is greatly affected by light, and achieves high position repeatability, The effect of reducing false detection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

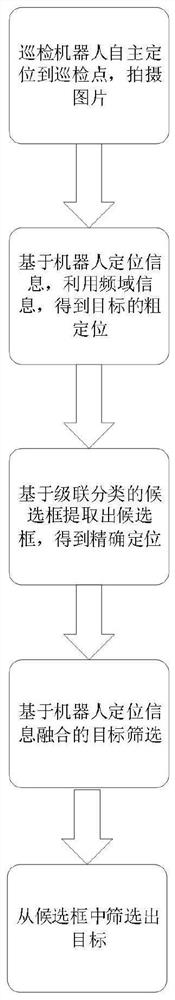

[0068] A power meter detection method that integrates the positioning information of an inspection robot, the specific steps are:

[0069] Step 1-1. Collect the pictures of the on-site inspection points collected by the inspection robot, extract the images of the electric meters from them, and make a 48*48 grayscale image data set according to the classification of the meters, such as figure 2 As shown, the image data set is sent to the classifier for training;

[0070] Step 1-2. Select an image in the center of the inspection instrument from the pictures taken at each inspection point, such as image 3 Shown as the template image for detection;

[0071] Step 1-3. The inspection robot reaches the designated inspection point through positioning and navigation, with a navigation error of 5cm, and takes an image A for instrument inspection;

[0072] Step 2. Perform Merlin Fourier transform and phase correlation calculation on the image A taken by the inspection robot and the t...

Embodiment 2

[0088] A power meter detection method that integrates the positioning information of an inspection robot, the specific steps are:

[0089] Step 1. The inspection robot reaches the designated inspection point through positioning and navigation, with a navigation error of 5cm, and takes an image A for instrument inspection;

[0090] Step 2. Perform Merlin Fourier transform and phase correlation calculation on the image A taken by the inspection robot and the template image B of the current inspection point, and obtain the image displacement index (-12,33) of the abscissa and ordinate, Calculate the estimated position of the instrument in image A (984,502,103,86);

[0091] Step 3. Use the pre-trained machine learning Adaboost classifier to accurately locate the image to be detected, and obtain multiple target candidate areas such as Figure 5 As shown; according to the Adaboost classifier, one candidate box (with numbers) is obtained, and the boxes without numbers are obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com