A liquid level instrument identification method based on a patrol inspection robot

An inspection robot and identification method technology, applied in the field of electric inspection robots, can solve the problems of unstable indication, complex lighting conditions, different shooting angles of inspection robots, etc., and achieve the effect of reducing missed inspections and high position repetition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

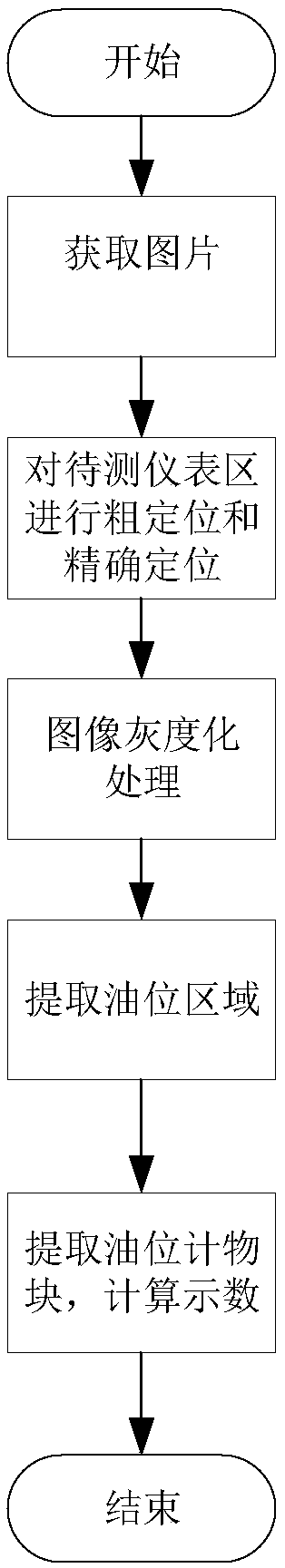

[0012] Such as figure 1 As shown, the liquid level instrument identification method based on the inspection robot includes the following steps:

[0013] Step 1. Classifier training: Use the instrument image dataset to train the Adaboost classifier, and select an image centered on the instrument as a template image for each inspection point. Since the instrument image data set contains instrument images under different lighting and attitude conditions, any changes in the subsequent instrument detection environment can be accurately extracted.

[0014] Step 2. Instrument area positioning: Obtain the image of the instrument to be inspected at the specified inspection point, combine the Adaboost classifier and the template image for rough positioning and precise positioning, and filter out the dial area. The specific method is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com