Rotary piston machine

A rotary piston and machine technology, applied in the field of rotary piston machines, can solve problems such as limited adaptability, achieve the effect of reducing leakage loss and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

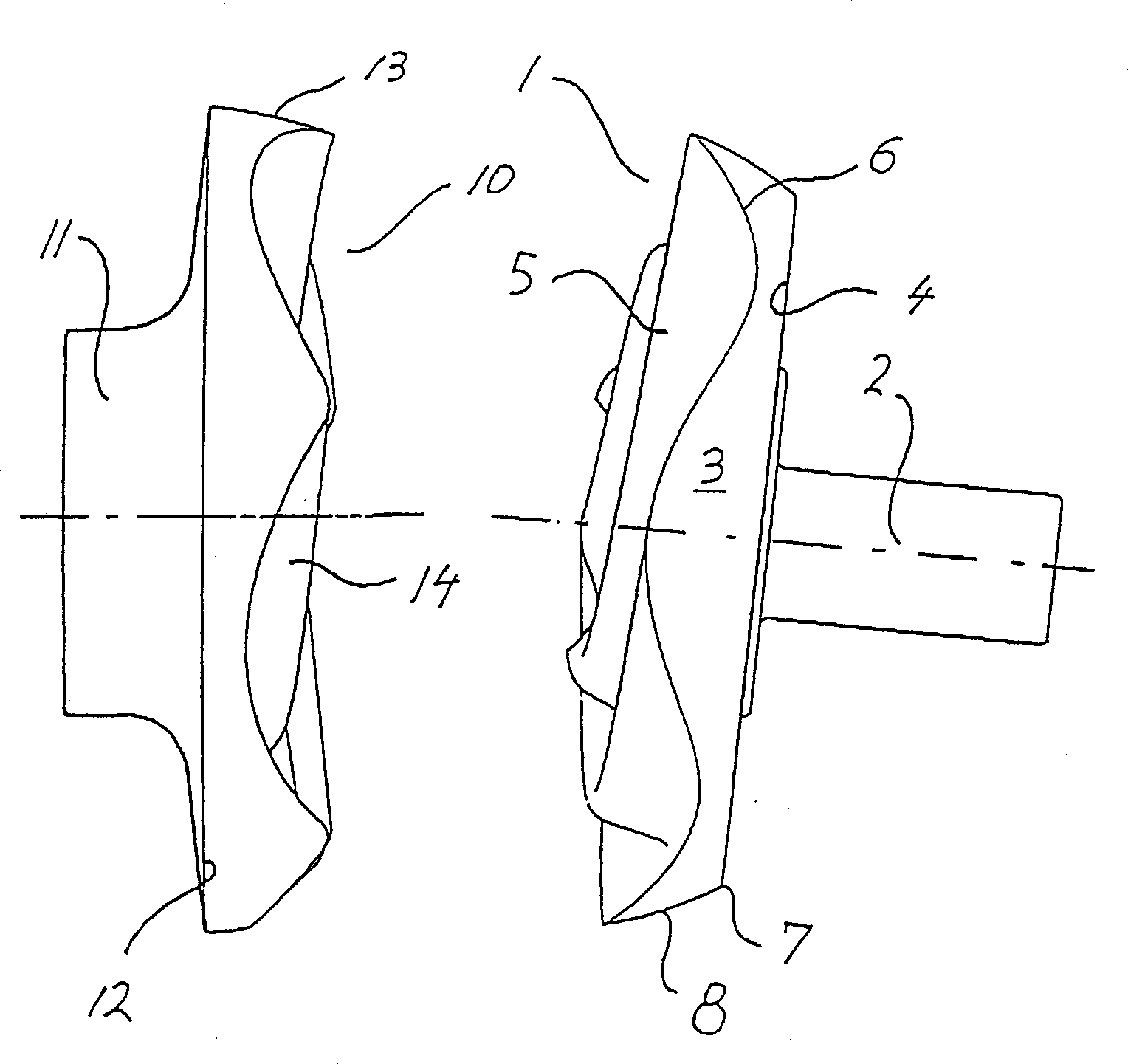

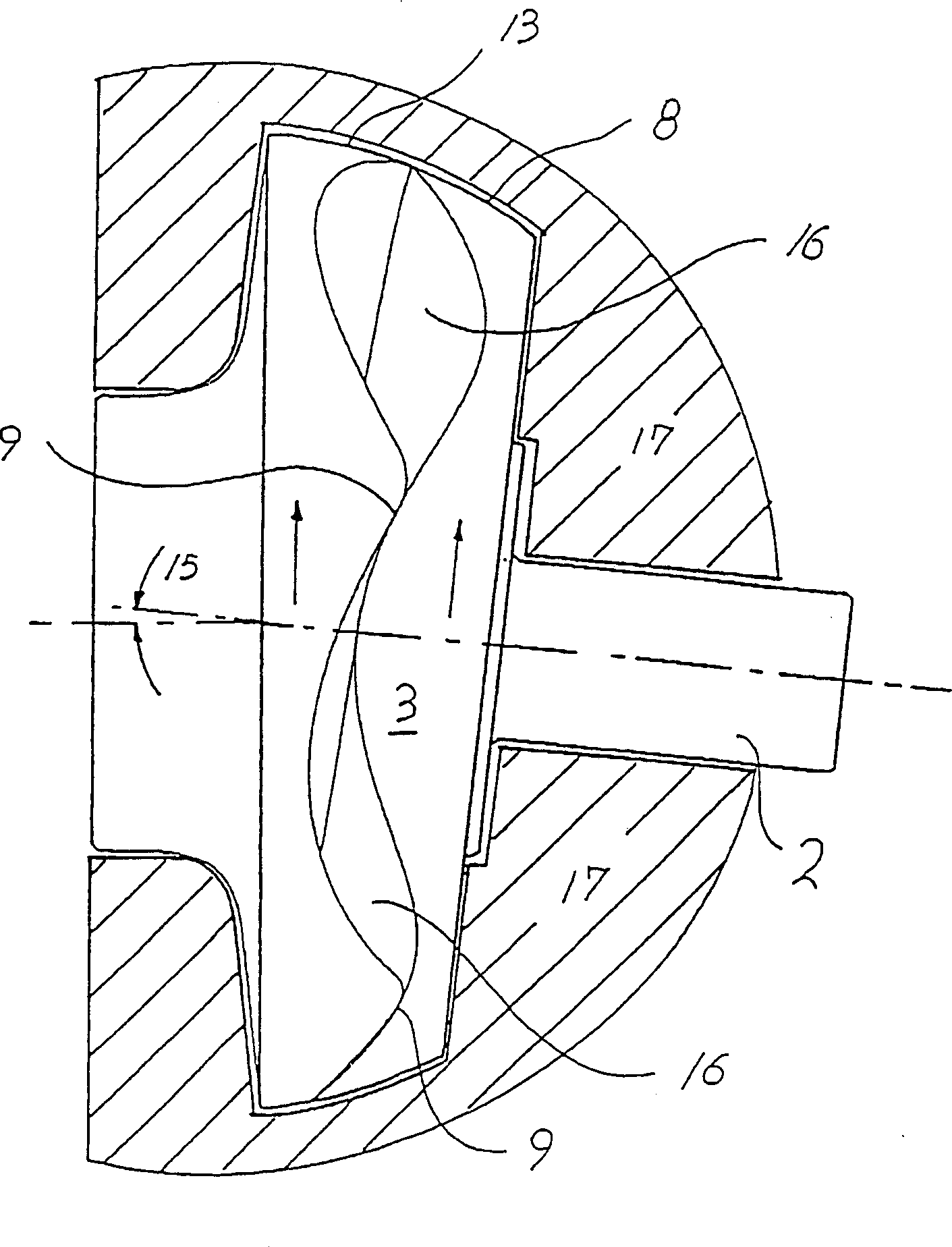

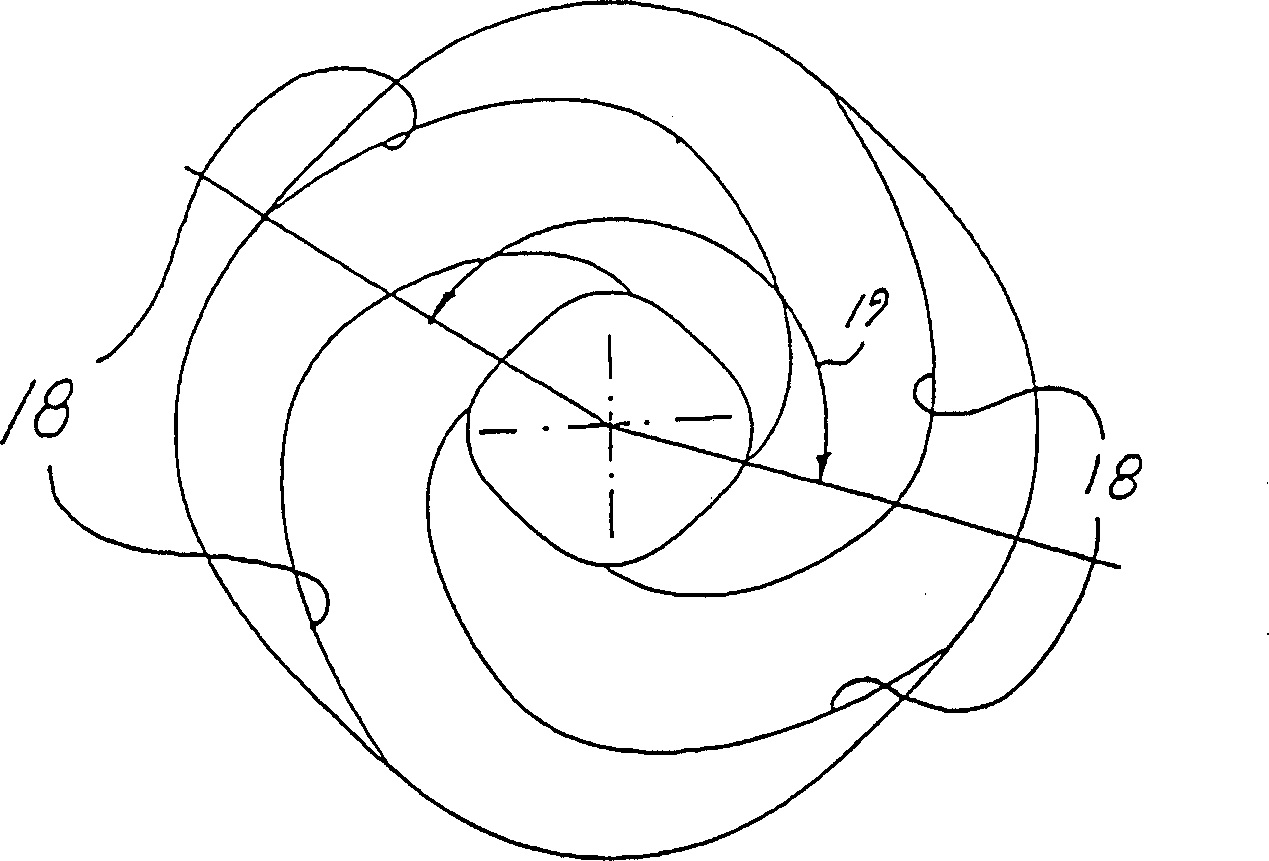

[0027] figure 1 The right side shows the power section 1 and the drive or output shaft 2 . A drive or output shaft 2, supported in a housing not shown in the figures, carries the power part 1 at one end thereof. The power part 1 is formed by a spherical section 3 which is bounded in the direction of the drive or output shaft 2 by a flat base 4 and whose end face 5 has helical cycloidal teeth. Different from the conventional cycloid structure, the cycloid 6 is formed by rolling a circle on the intersection line 7 between the spherical surface 8 and the bottom surface 4 , wherein the point of the circle describing the cycloid 6 is always on the spherical surface 8 . Cycloid 6 is the dominant curve required for gearing. A straight cycloidal tooth is produced when a straight generatrix moves along the dominant curve 6 around a fixed point on the axis of rotation of the drive or output shaft 2 . If instead of a straight generatrix a helical generatrix is used, the helical cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com