Online sampling system for gas-liquid mixed medium

A gas-liquid mixing and sampling system technology, applied in the petrochemical field, can solve problems such as inability to meet the sampling requirements of complex working conditions, and achieve the effect of eliminating medium residue and simplifying the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

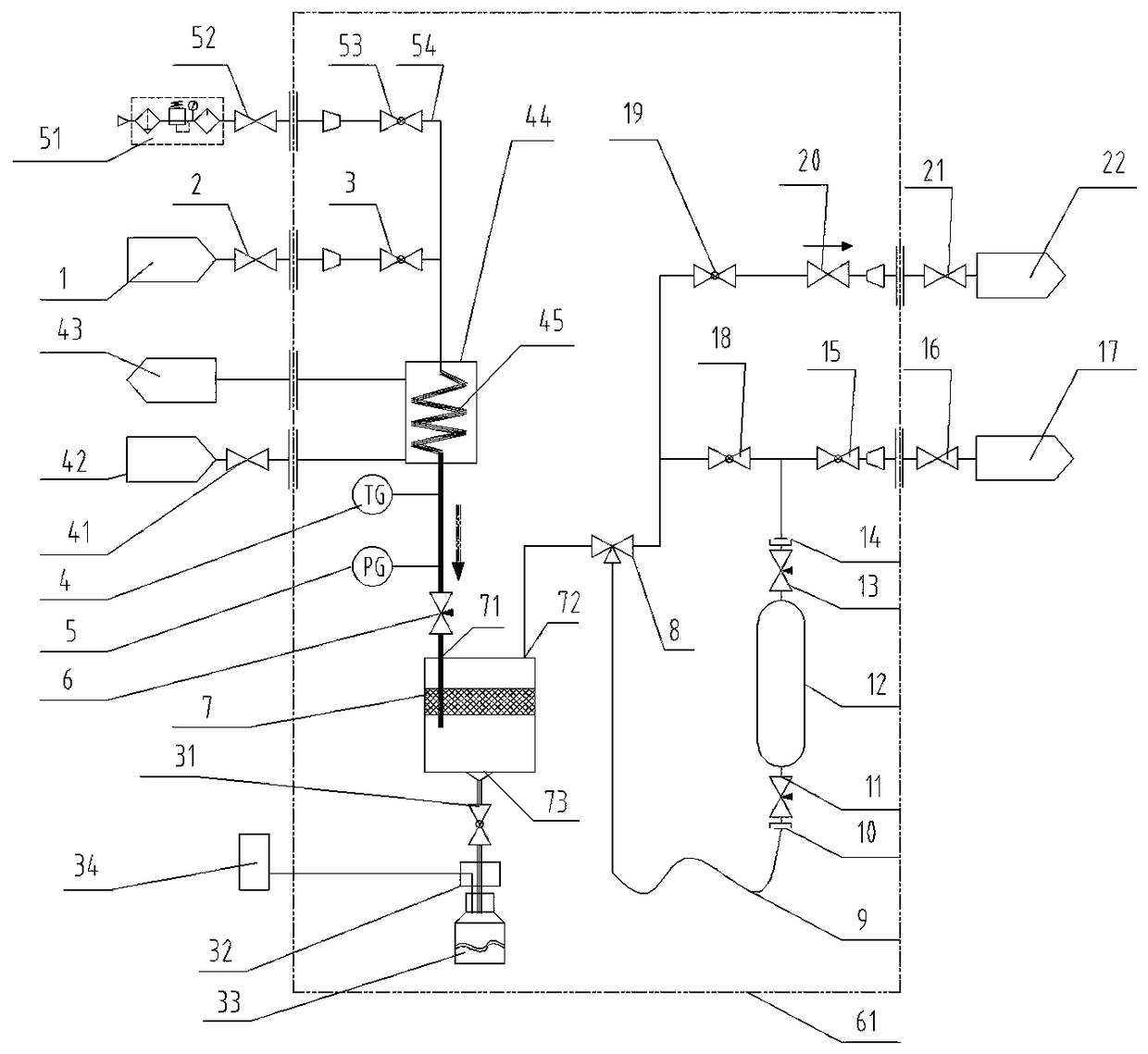

[0028] see figure 1 , an on-line sampling system for a gas-liquid mixed medium, comprising a sampling system, a gas-liquid separation system, a cooling system, and a nitrogen purging system.

[0029] Among them, the sampling system includes a medium inlet 1, a first medium inlet process valve 2, a second medium

[0030] Quality inlet process valve 3, liquid sampling valve 6.

[0031] Specifically, the liquid sampling valve 6 communicates with the top of the gas-liquid separation system. The bottom of the gas-liquid separation system communicates with the inside of the glass bottle 33 through the sampling needle 32 and a sampling valve 31 is provided between the gas-liquid separation system and the sampling needle 32 . The adsorption tank 34 communicates with the inside of the glass bottle 33 through the sampling needle 32 .

[0032] Specifically, the first end of the three-way ball valve 8 communicates with the top of the gas-liquid separation system. The second end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com