Liquid sampler

A liquid sampling and liquid technology, applied in the field of samplers, can solve problems such as large vibration force, slurry leakage in frozen holes, and incompact soil backfill in the wellbore, and achieve the effects of improving accuracy, high sampling success rate, and shortening drilling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

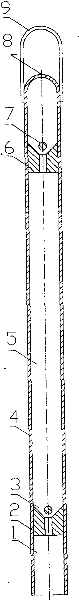

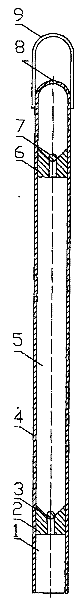

[0018] As shown in the figure, a liquid sampler is composed of a tube body (4) blocked at one end, a handle (9) is provided at the plugged end of the tube body (4), and a blocking plate at the blocked end of the tube body There is a liquid outlet (7) on the top, and an upper normally closed self-returning liquid one-way valve (6) and a lower normally closed self-returning liquid one-way valve (6) are arranged in the lumen of the pipe body (4) at a certain distance. (2), the upper and lower normally closed self-returning liquid one-way valves divide the lumen into an upper chamber (7), a middle chamber (5) and a lower chamber (1). The blocking plate at the blocking end of the pipe body is a spherical cap, the inner radius of the spherical cap is the same as the inner radius of the pipe body (4), and the outer radius of the spherical cap is the same as the outer radius of the pipe body (4). The inner diameter of the pipe body (4) is 40mm, the outer diameter of the pipe body (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com