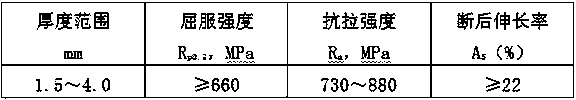

Production process of thin gauge 700mpa grade ultra-high strength hot-rolled black steel strip

A production process and thin-gauge technology, which is applied in the field of hot-rolled steel strip production technology, can solve problems such as affecting the quality of painting, and achieve the effects of reducing the weight of the whole vehicle, densifying the scale of iron oxide, and improving the processing environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The production process of the ultra-high-strength hot-rolled black steel strip is specifically as follows.

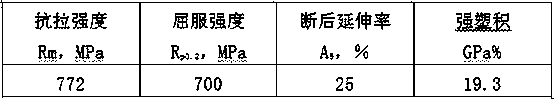

[0022] After converter smelting, LF furnace refining, and slab continuous casting processes, the mass percentages of the chemical components of the obtained billets are: C0.07%, Mn 1.15%, Cr 0.20%, Mn+Cr 1.35%, S 0.003%, P 0.014 %, Si 0.21%, Als 0.032%, Nb0.015%, Ti 0.105%, Nb+Ti 0.120%, the rest is iron and unavoidable impurities; billet thickness 200mm. The total residence time in the heating furnace is 200 minutes, the heating temperature in the soaking section is 1300°C, and the soaking time is 40 minutes. After rough rolling and finish rolling, it is rolled into a steel strip with a thickness of 2.5mm; the thickness of the intermediate billet is 30mm, the temperature of the advanced and finish rolling is 1070°C, and the temperature of the final rolling is 860°C. The steel strip is rapidly cooled to 770°C first, then air-cooled for 5 seconds in...

Embodiment 2

[0026] Embodiment 2: The production process of the ultra-high-strength hot-rolled black steel strip is specifically as follows.

[0027] After converter smelting, LF furnace refining, and slab continuous casting processes, the mass percentages of the chemical components of the obtained billets are: C0.07%, Mn 1.10%, Cr 0.50%, Mn+Cr 1.60%, S 0.003%, P 0.012 %, Si 0.08%, Als 0.032%, Nb0.050%, Ti 0.07%, Nb+Ti 0.120%, the rest is iron and unavoidable impurities; billet thickness 230mm. The total residence time of the heating furnace is 240 minutes, the heating temperature in the soaking section is 1280°C, and the soaking time is 48 minutes. After rough rolling and finish rolling, it is rolled into a steel strip with a thickness of 4.0mm; the thickness of the intermediate billet is 35mm, the temperature of the advanced and finish rolling is 1030°C, and the temperature of the final rolling is 880°C. The steel strip is rapidly cooled to 760°C first, then air-cooled for 8 seconds in ...

Embodiment 3

[0031] Embodiment 3: The production process of the ultra-high-strength hot-rolled black steel strip is specifically as follows.

[0032]After converter smelting, LF furnace refining, and slab continuous casting processes, the mass percentages of the chemical components of the obtained billet are: C0.05%, Mn 1.60%, Cr 0.03%, Mn+Cr 1.63%, S 0.002%, P 0.015 %, Si 0.15%, Als 0.025%, Nb0.001%, Ti 0.12%, Nb+Ti 0.121%, the rest is iron and unavoidable impurities; billet thickness 180mm. The total residence time in the heating furnace is 180 minutes, the heating temperature in the soaking section is 1320°C, and the soaking time is 35 minutes. After rough rolling and finish rolling, it is rolled into a steel strip with a thickness of 1.5mm; the thickness of the intermediate billet is 36mm, the temperature of the advance and finish rolling is controlled at 1100°C, and the temperature of the finish rolling is 830°C. The steel strip is rapidly cooled to 750°C first, then air-cooled for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com