High-efficiency autotrophic denitrification system and operation method for treating high-ammonia nitrogen wastewater

An autotrophic denitrification, high ammonia nitrogen technology, applied in sustainable biological treatment, water treatment parameter control, chemical instruments and methods, etc. Requirements, flexible operation mode, high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

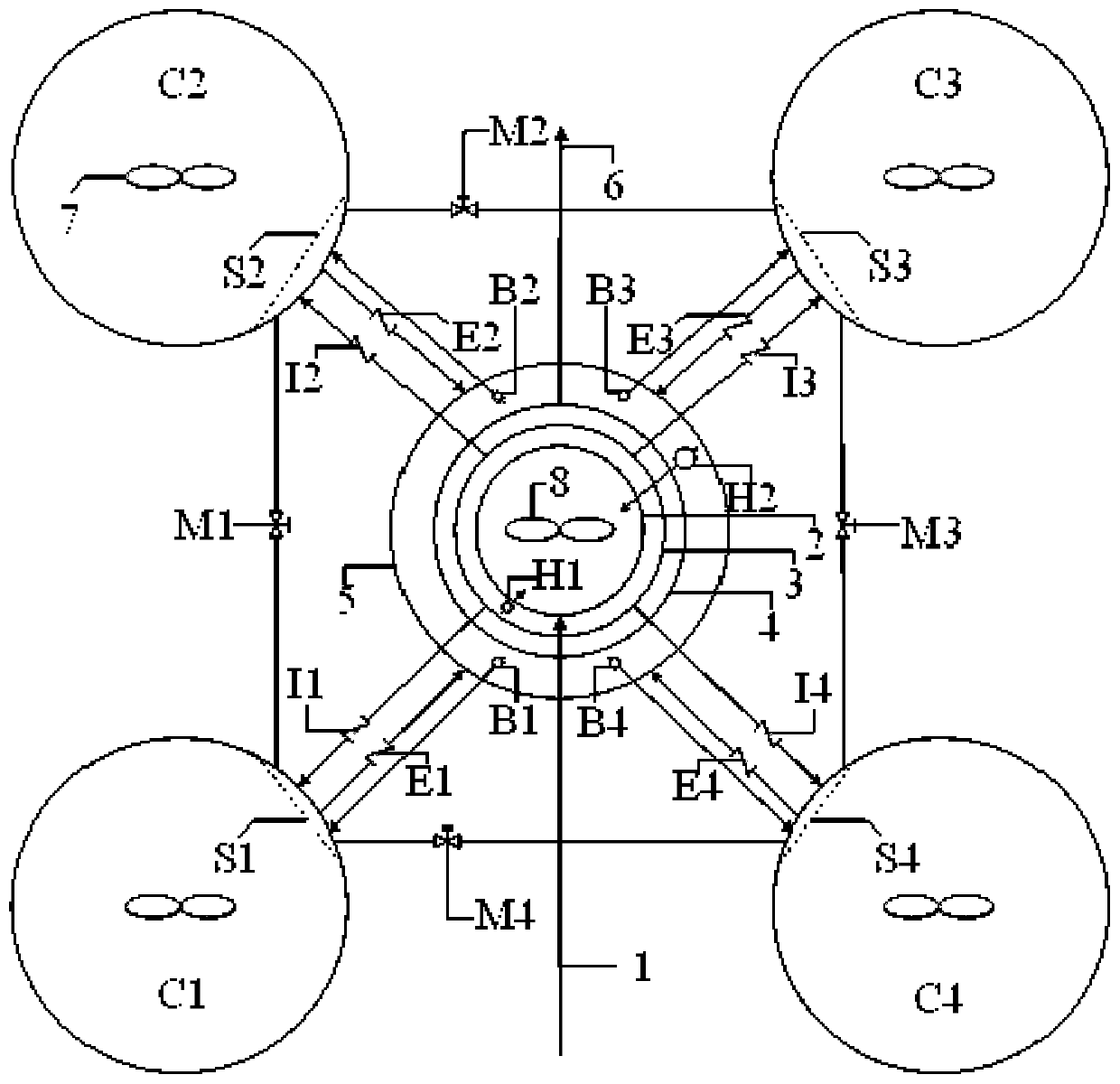

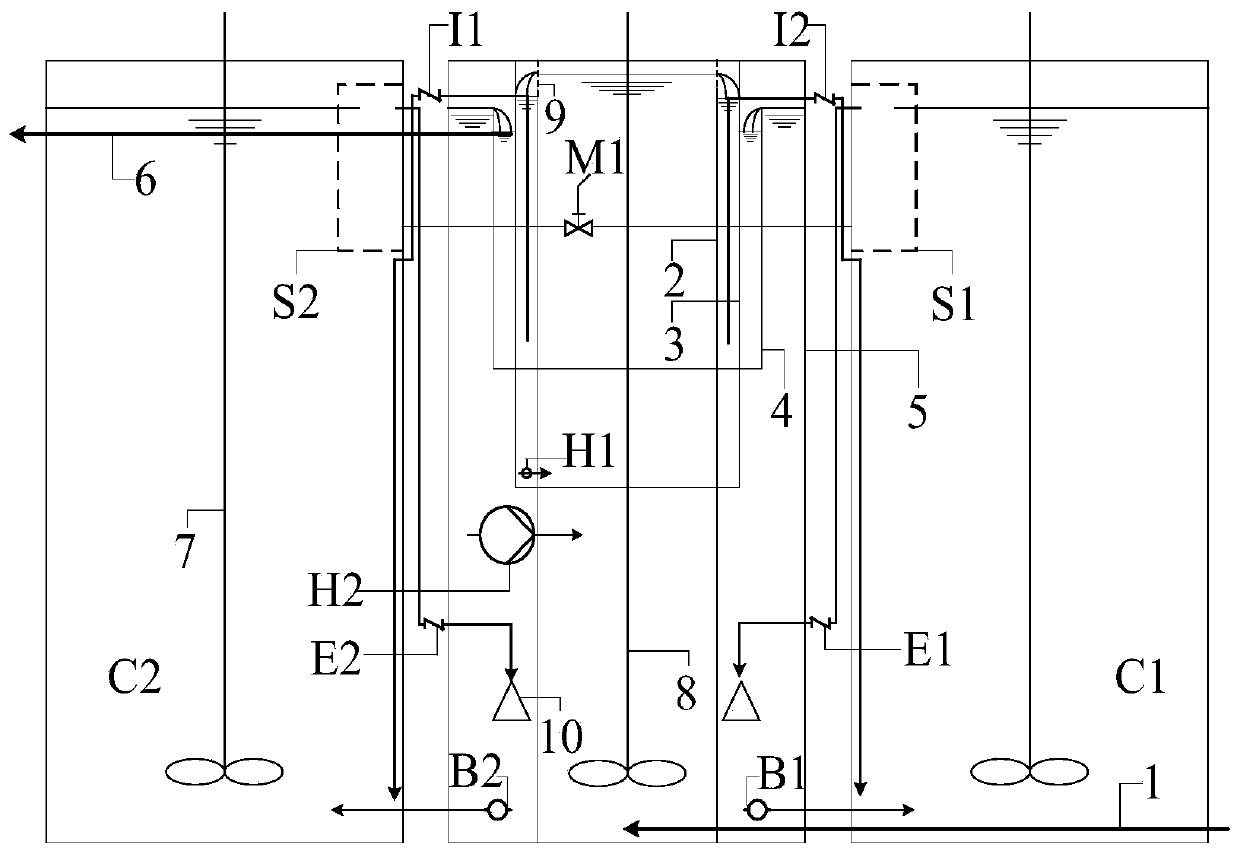

[0120] The high-concentration ammonia-nitrogen wastewater produced in the production process of a bioengineering company is used as the system feed water, with a water volume of 3000m 3 / d, the average pH value is 7.9, the average water temperature is 32°C, the average COD concentration in the influent water is 2500mg / L, and the BOD 5 The average concentration is 1500mg / L, the average ammonia nitrogen concentration is 800mg / L, the average nitrous nitrate concentration is 2.0mg / L, and the average alkalinity (calculated as CaCO 3 total) 5000mg / L, the total effective volume of the reaction pool is 800m 3 , the effective volume of the denitrification tank is 800m 3 , the influent enters the four reaction pools C1-C4 through the denitrification pool.

[0121] In preparation for start-up, a suspension carrier is added to each reaction tank and denitrification tank, and the effective specific surface area of the carrier is 800m 2 / m 3 , with a porosity of 90%, in line with the ...

Embodiment 2

[0130] The sludge digestion solution used in the test is the dewatered filtrate after sludge digestion in a sewage treatment plant. The sewage treatment plant adopts the medium temperature anaerobic digestion process to treat the sludge, and the solid content of the sludge is 10%. Water volume 2000m 3 / d, pH value 7.8-7.9, average water temperature 30°C, average influent COD concentration 810mg / L, BOD 5 The average concentration is 620mg / L, the average ammonia nitrogen concentration is 560mg / L, and the total effective volume of the reaction pool is 400m 3 , divided into four reaction pools on average, and the effective volume of each reaction pool is 100m 3 , the effective volume of the denitrification pool is 100m 3 , Influent water enters four reaction pools C1-C4 after passing through the denitrification pool.

[0131] In preparation for start-up, a suspension carrier is added to each reaction tank and denitrification tank, and the effective specific surface area of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com