Hydraulic die forging machine

A hydraulic die forging and injection mechanism technology, applied in the field of hydraulic die forging machines, can solve the problems of low productivity, low yield, high labor cost, etc., and achieve the effect of high die casting quality and rapid and efficient die replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

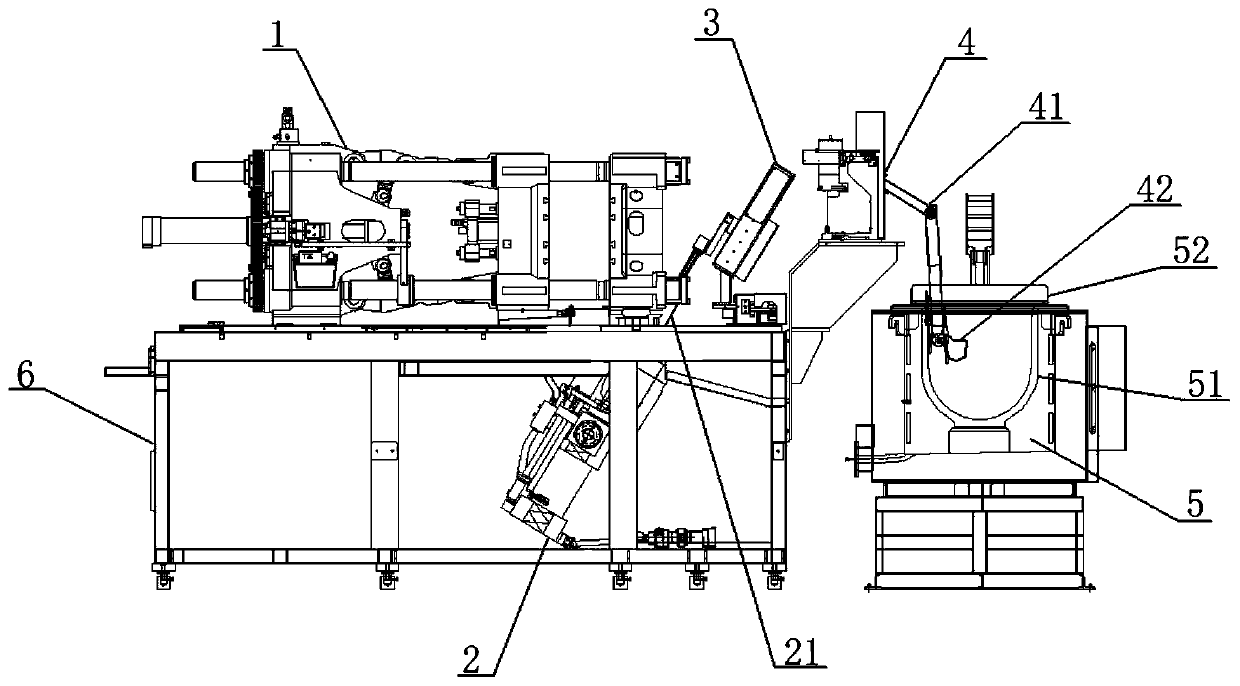

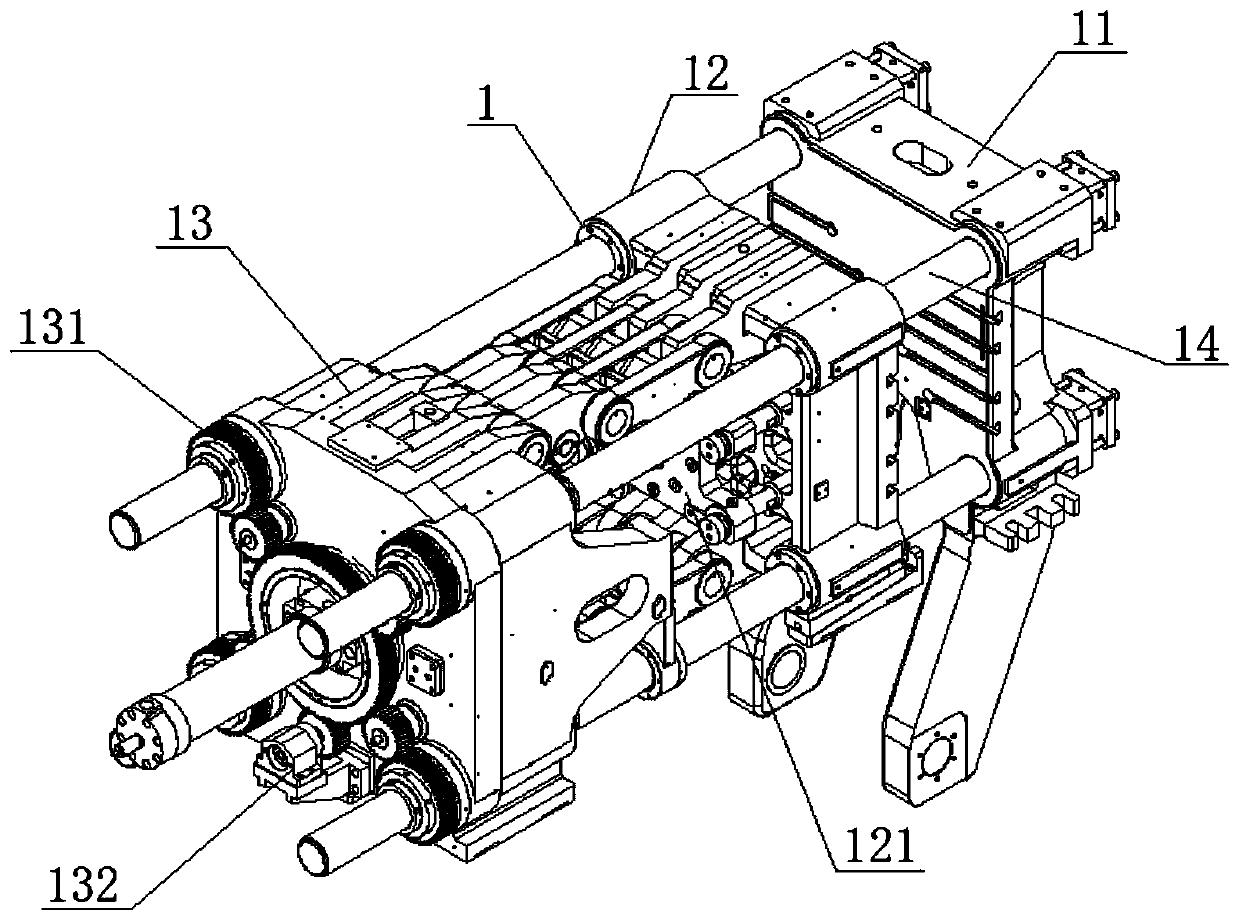

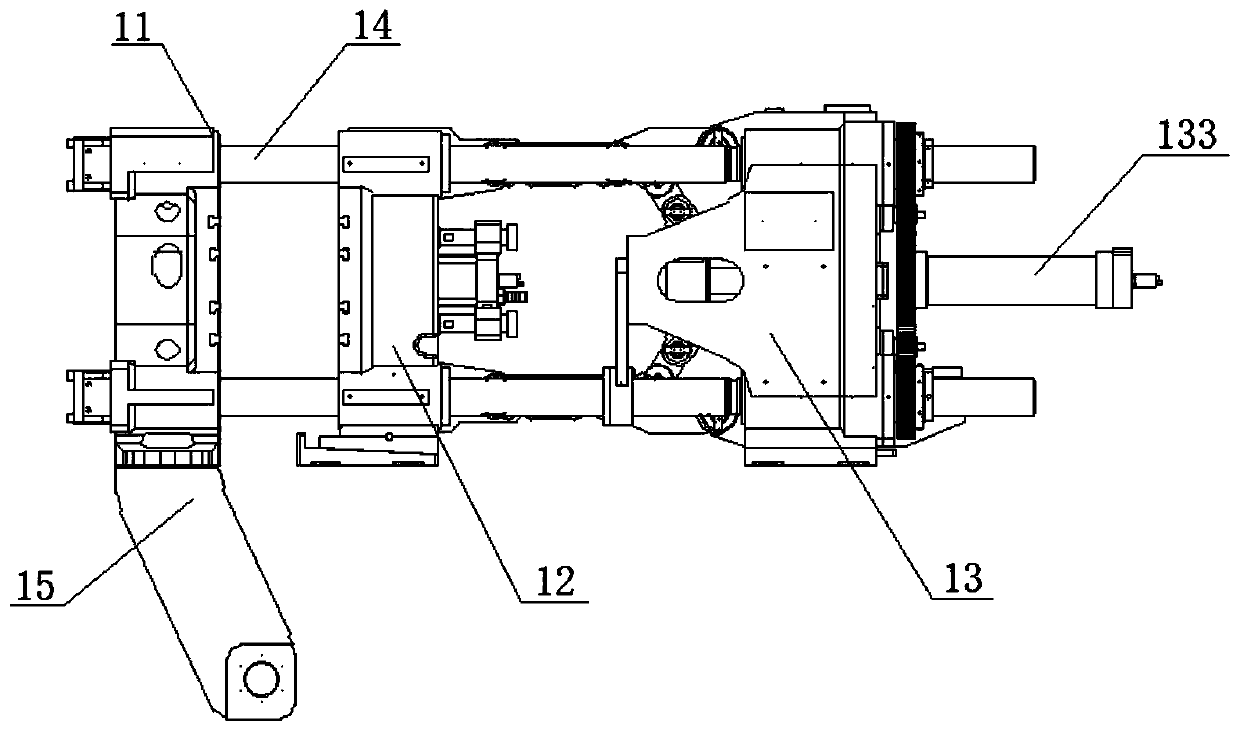

[0030] Such as Figure 1-7 As shown, the present invention discloses a hydraulic die forging machine, comprising a mold opening and closing mechanism 1, an injection mechanism 2, a spraying machine 3, a soup feeder 4, a holding furnace 5 and a frame 6, and the mold opening and closing mechanism 1 lies horizontally Installed above the frame 6, the injection mechanism 2 is rotatably installed on the lower part of the mold opening and closing mechanism 1, the spraying machine 3 is fixedly installed on the front of the frame 6, and the front end of the injection mechanism 2 is provided with a material chamber 21 , the sprayer 3 can clean, cool and lubricate the material cavity 21, the soup feeder 4 is also installed at the front of the frame 6, and the soup feeder 4 is located in front of the sprayer 3, the soup feeder The machine 4 includes an end holding mechanism 41 and a soup ladle 42. The soup ladle 42 is driven by the end holding mechanism 41 to carry materials. The holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com