Horizontal stirring machine

A technology of horizontal mixer and mixing tank, which is applied in the direction of mixer accessories, mixers, mixing methods, etc., and can solve the problems of inability to realize continuous feeding, low mixing efficiency, and inability to ensure the uniformity of mixing of multi-component high-viscosity materials, etc. Achieve the effects of easy cleaning, prolonging the stirring time and preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

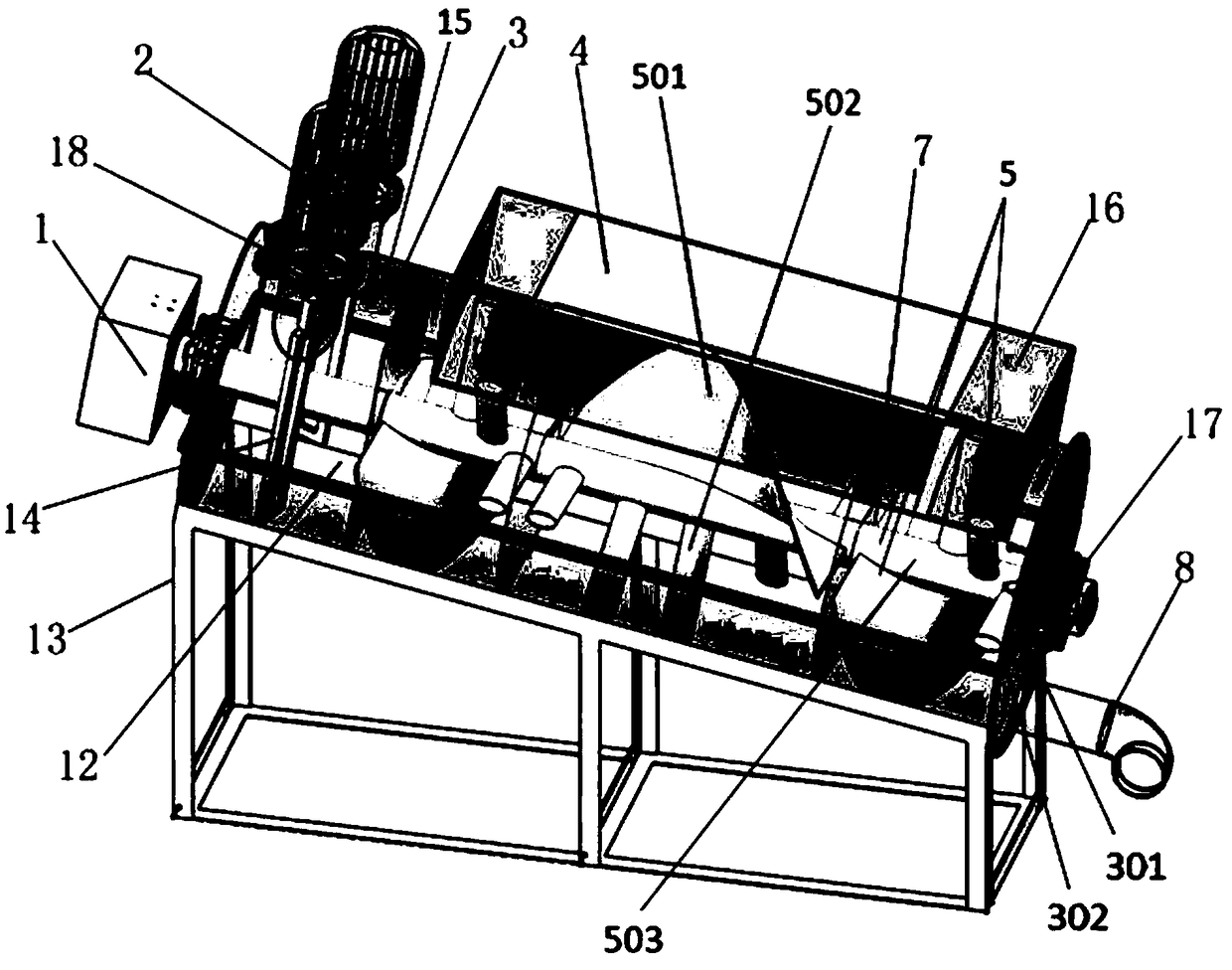

[0024] A horizontal mixer such as figure 1 As shown, a stirring tank 3 is included, an agitator 5 is arranged in the agitating tank 3, a first power system 1 for driving the agitator 5 is arranged outside the agitating tank 3, and a feed passage 15 and a discharge channel 15 are arranged on the agitator. channel 8;

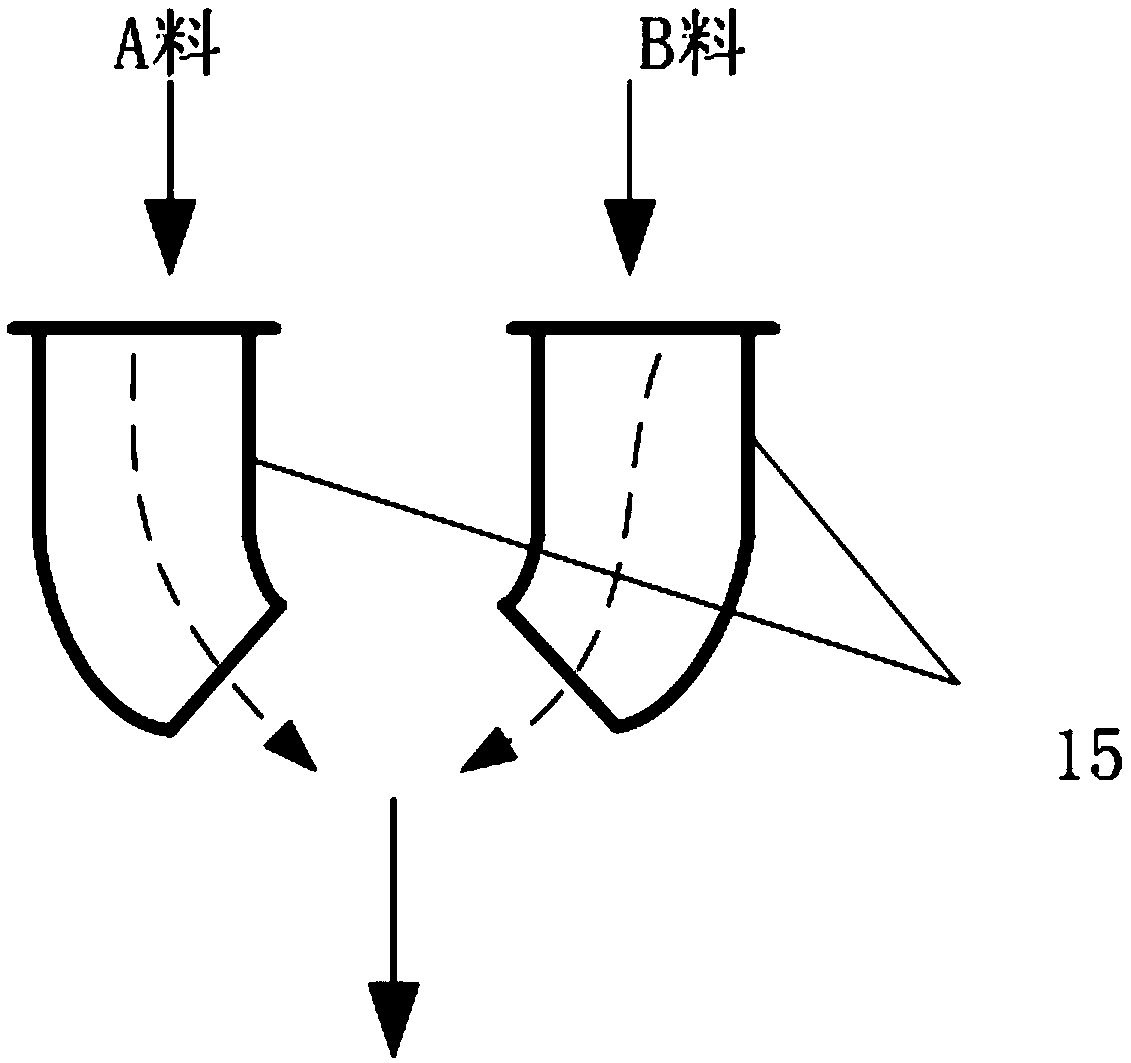

[0025] Wherein, one end of the stirring tank 3 is provided with a premixing device communicated with the stirring tank 3, a buffer tank 4 communicating with the stirring tank 3 is arranged above the stirring tank 3, the stirrer 5 is axially arranged in the stirring tank 3, and the feed channel 15 Located on the premixing device, the discharge channel 8 is located at the end of the mixing tank 3 away from the premixing device;

[0026] Wherein, the mixing tank 3 is inclined, so that the end of the mixing tank 3 close to the premixing device is higher than the end of the mixing tank 3 away from the premixing device;

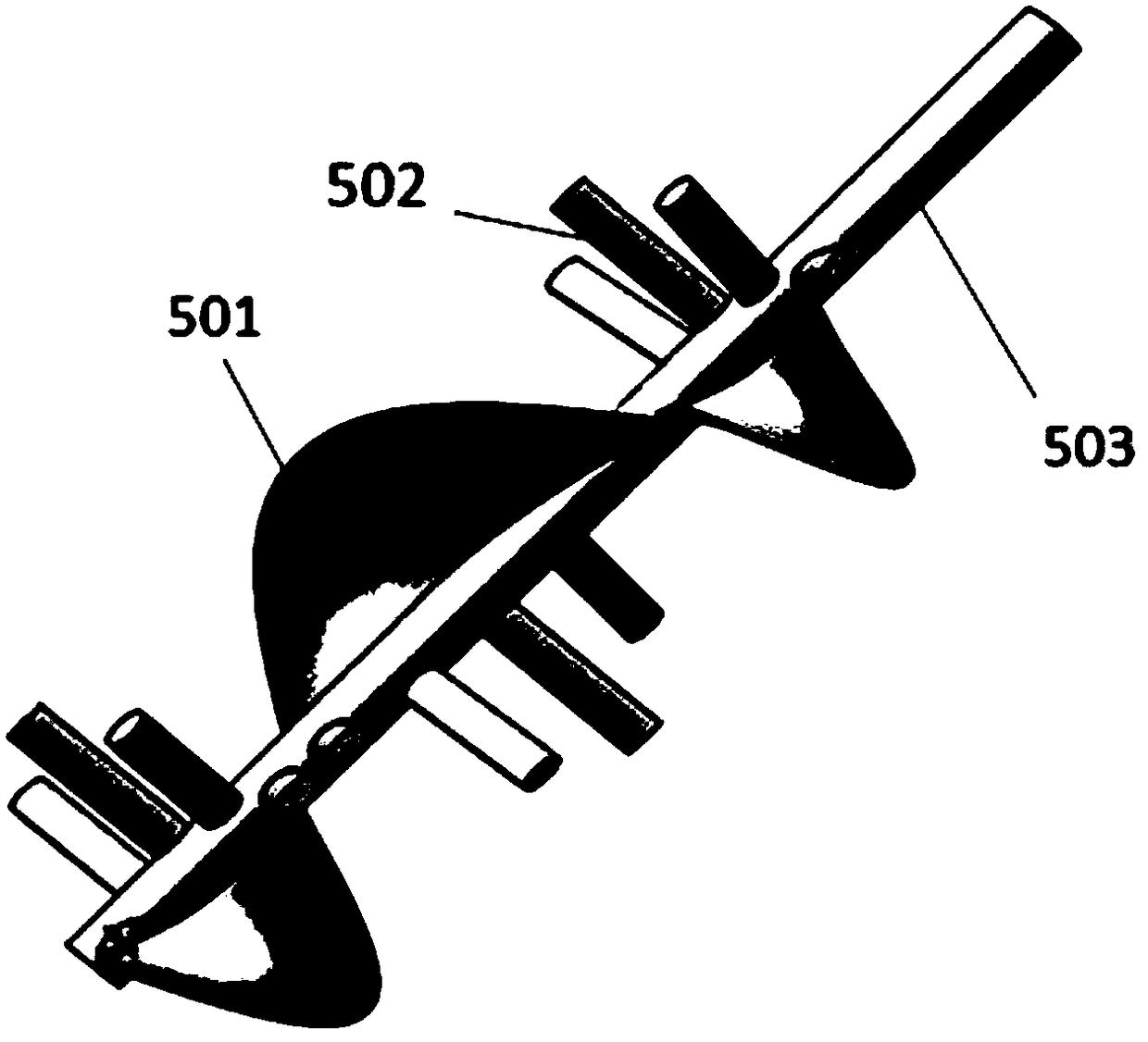

[0027] Among them, the mixer 5 such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com