Dye liquor pretreatment equipment for textile printing and dyeing

A technology for textile printing, dyeing and pretreatment, applied in textile-related fields, can solve the problems of easy clogging of dye liquor and equipment reduction, and achieve the effect of speeding up filtration and effective filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

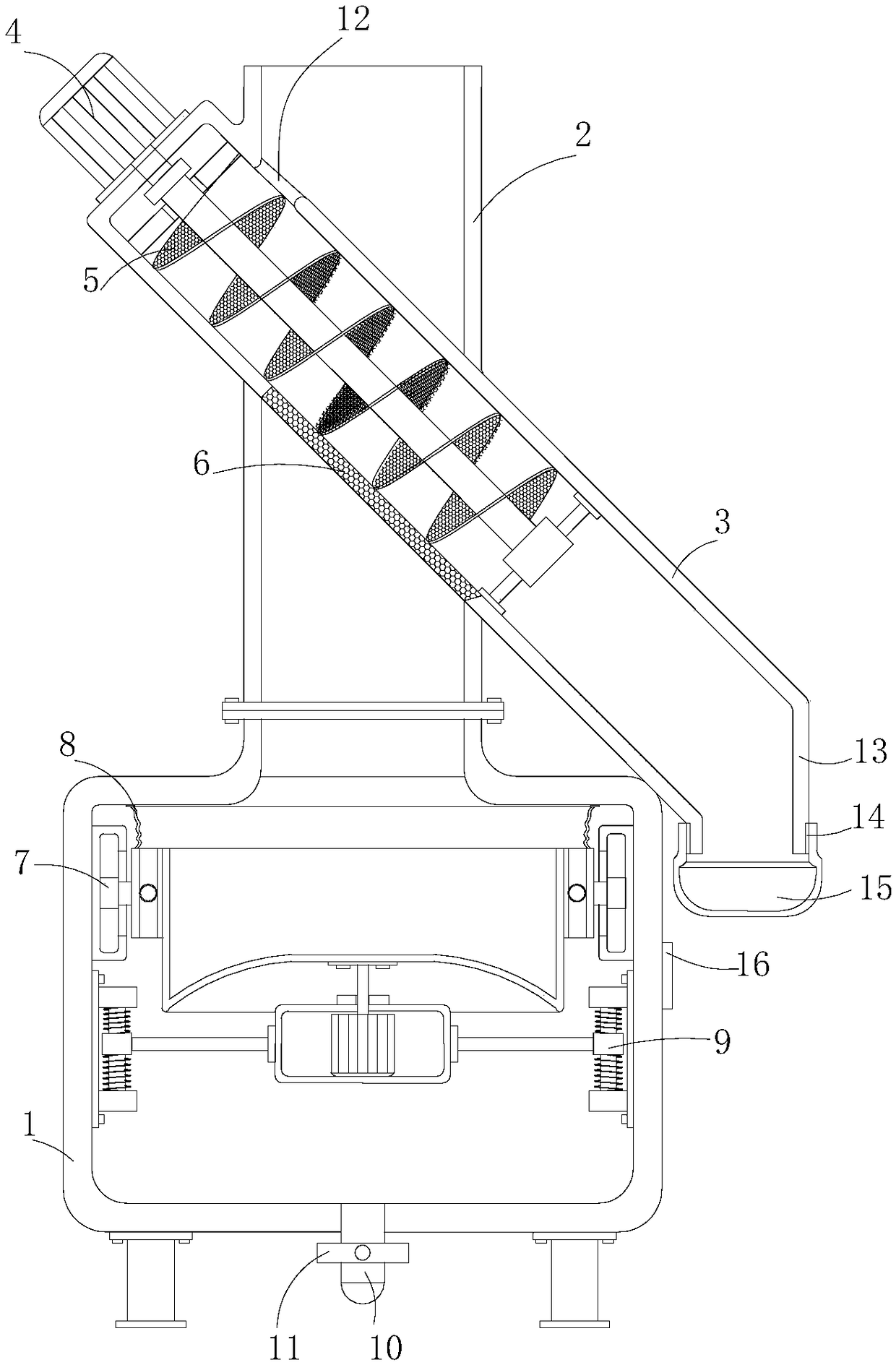

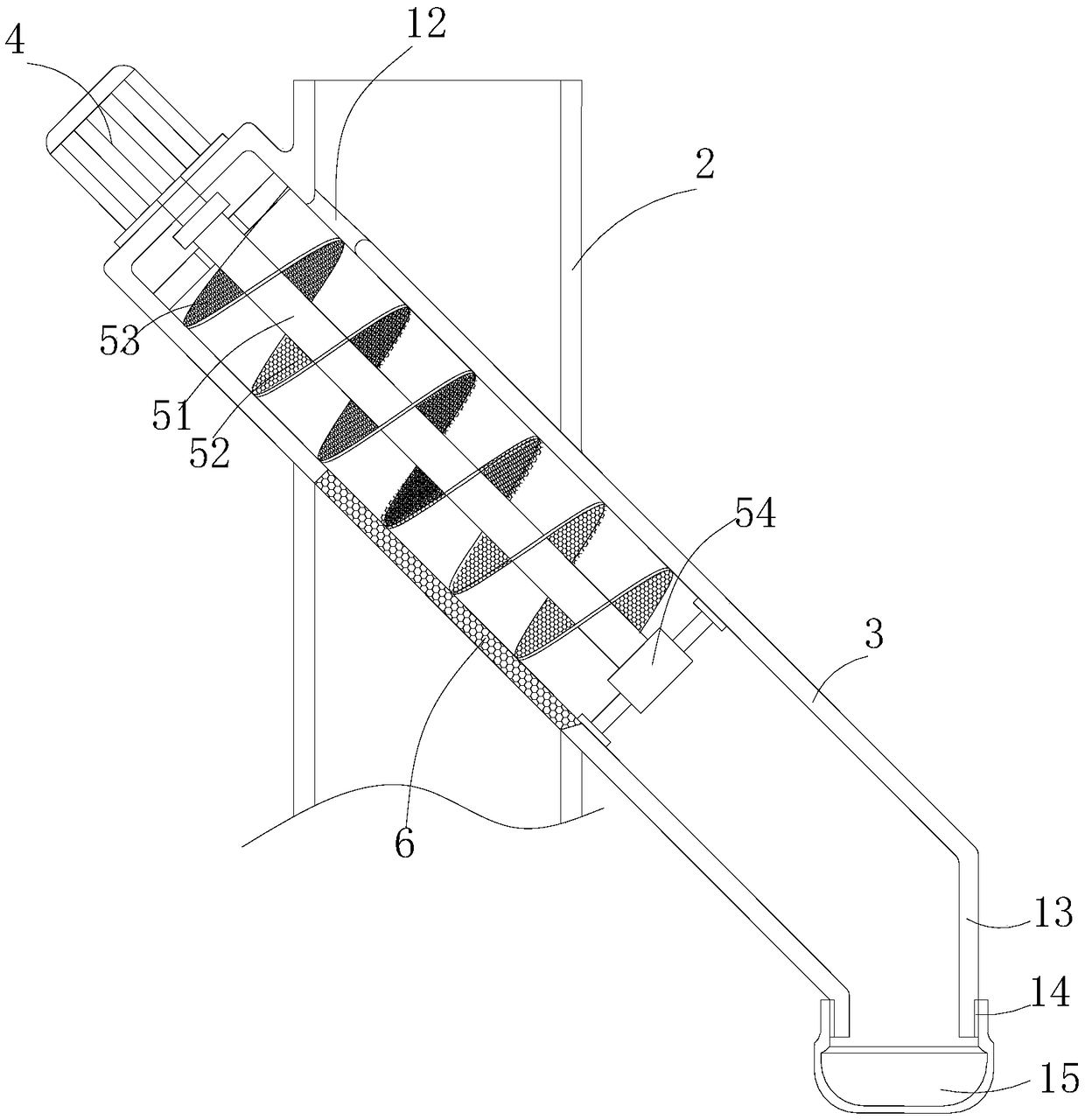

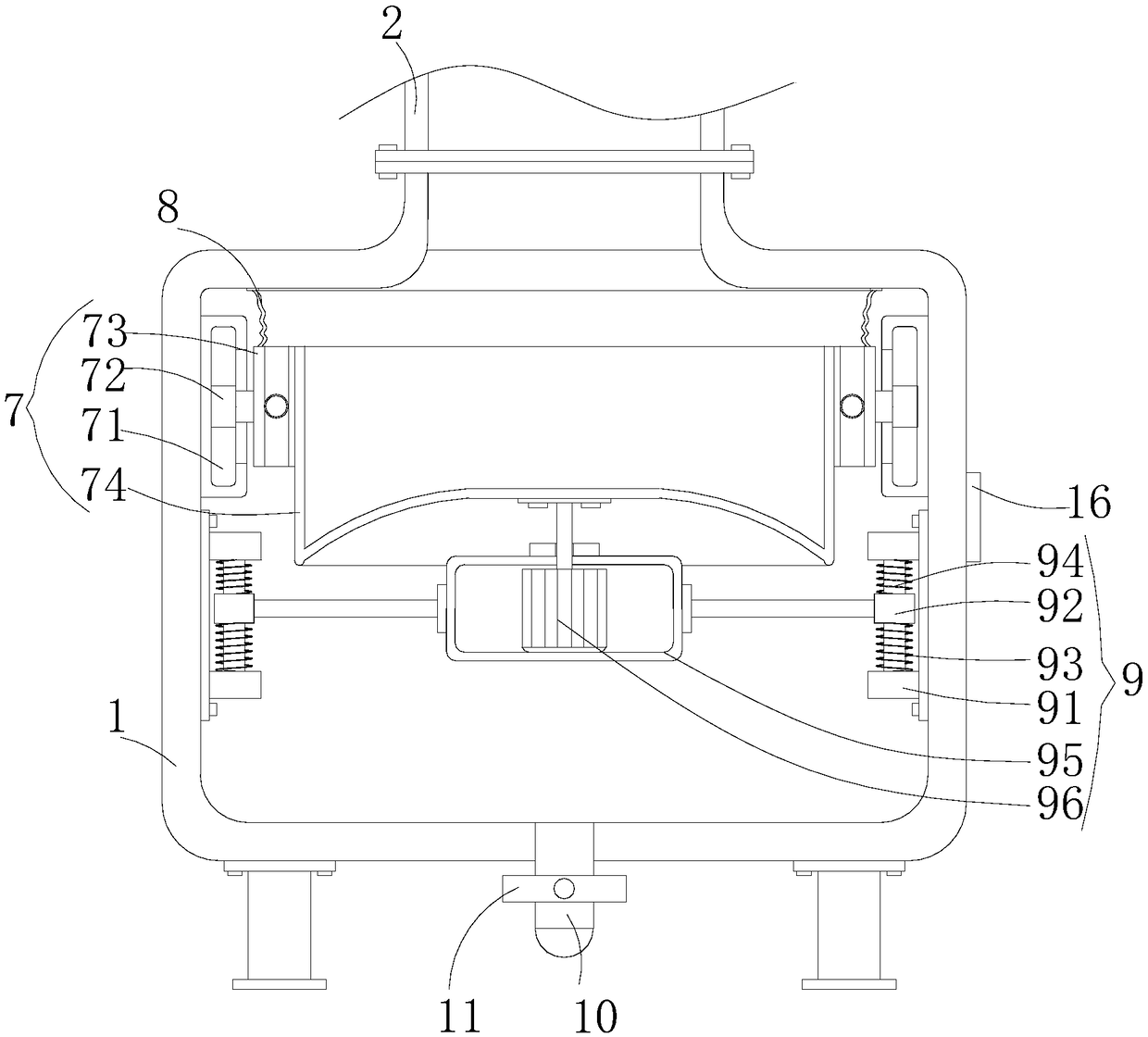

[0021] Such as Figure 1-3 As shown, the present invention provides a technical solution: a dye liquor pretreatment device for textile printing and dyeing, including a body 1, a vertical catheter 2, an oblique catheter 3, a low-speed motor 4, a filter residue pushing mechanism 5, a net Shaped hole 6, vertical connection mechanism 7, telescopic rubber sleeve 8, soft driving mechanism 9, drain pipe 10, switch valve 11, liquid guide port 12, bending section 13, external thread 14, miscellaneous cylinder 15 and control panel 16, The vertical catheter 2 is fixedly connected to the top of the body 1 by bolts, the oblique catheter 3 obliquely runs through the inclined through hole on the vertical catheter 2, and the oblique catheter 3 is located at the inner part of the vertical catheter 2. The outer wall is in sealing contact with the inner wall of the vertical catheter 2, and the inner side of the vertical catheter 2 is divided into two independent spaces. The low-speed motor 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com