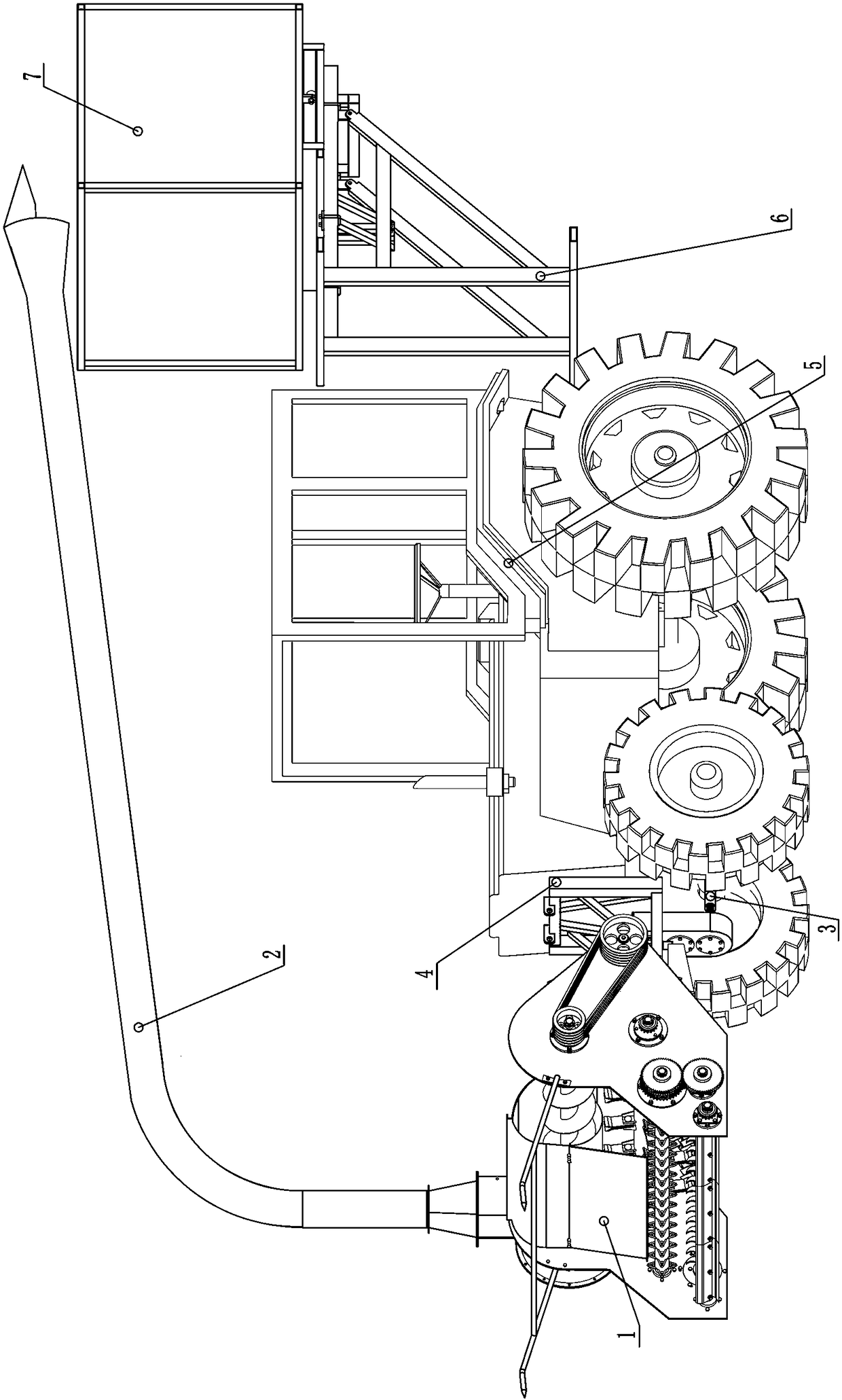

Feeding mechanism of crop harvesting machine and piggyback straw feed harvester

A technology of feeding mechanism and harvesting machinery, which is applied to agricultural machinery and implements, the chassis of agricultural implements, harvesters, etc., can solve the problems of low utilization rate, low operating efficiency, poor feed quality, etc., and achieve high operating efficiency and high performance. Reliable, good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

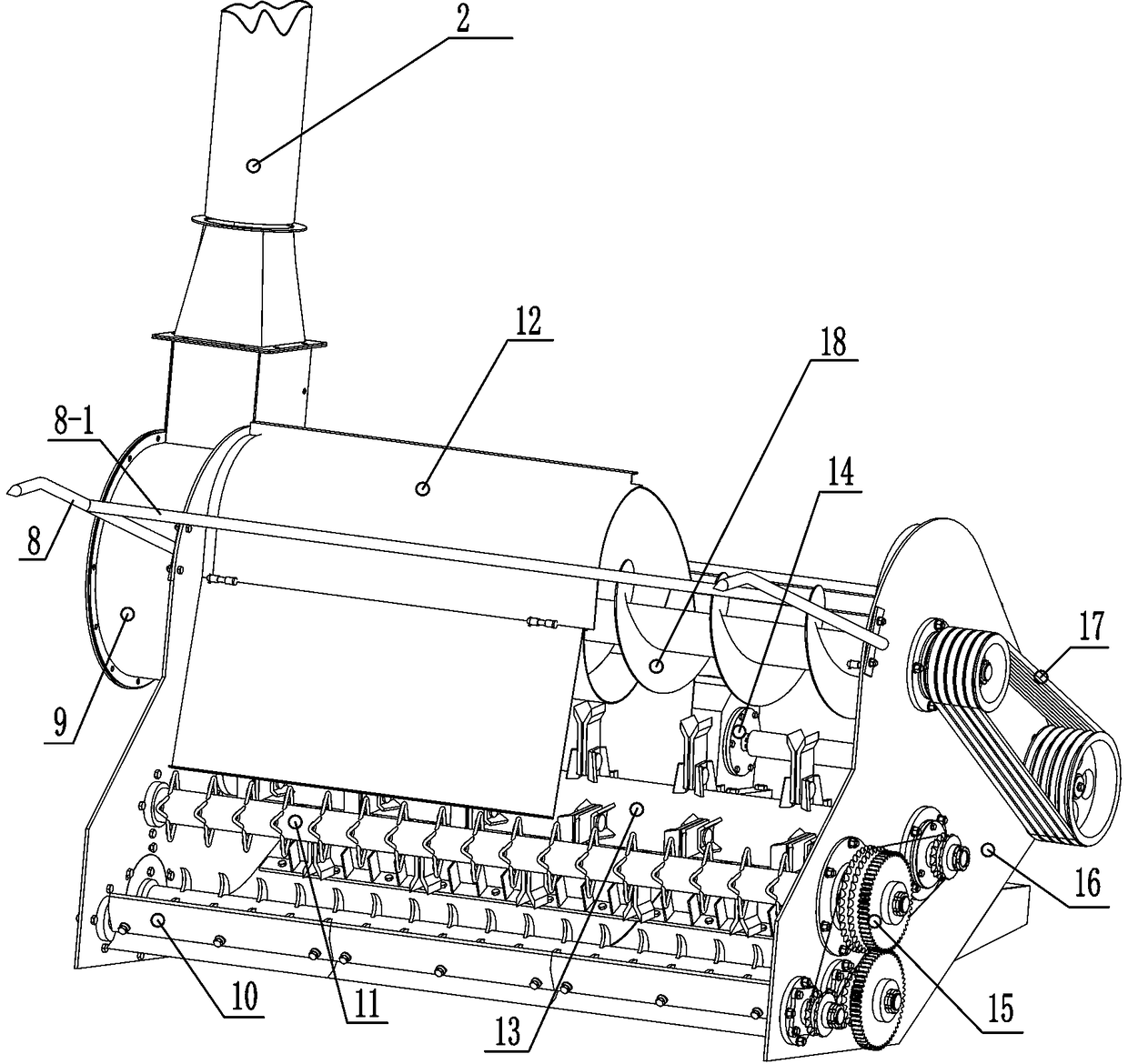

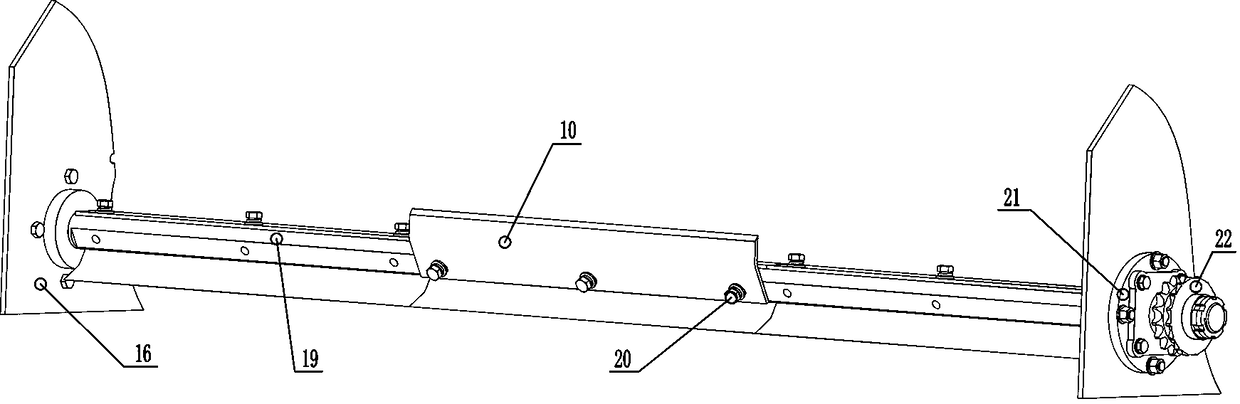

[0025]A feeding mechanism for a crop harvesting machine, comprising an upper feeding roller shaft 11, a lower feeding roller shaft 23, an upper feeding roller shifting tooth 25, a lower feeding roller shifting tooth 24, an upper feeding roller shifting tooth 25 and a lower feeding roller shifting tooth The shape and structure of the feed roller teeth 24 are different. The upper feed roller teeth 25 are equidistantly welded in the circumferential direction of the upper feed roller shaft 11, and the lower feed roller teeth 24 are welded equidistantly in the gap corresponding to the upper feed roller teeth 25. In the circumferential direction of the lower feeding roller shaft 23, the upper feeding roller shaft 11 and the lower feeding roller shaft 23 are powered by the power transmission mechanism to rotate, and the upper feeding roller shaft 11 is positioned at the upper rear of the lower feeding roller shaft 23. The upper feeding roller shifting tooth 25 is a polygonal star, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com