Transmission test apparatus based on circular grating

A technology of transmission test and circular grating, which is applied in the field of mechanical transmission, can solve the problems of lack of test devices and reduce the test cycle, and achieve the effect of improving the efficiency of test verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

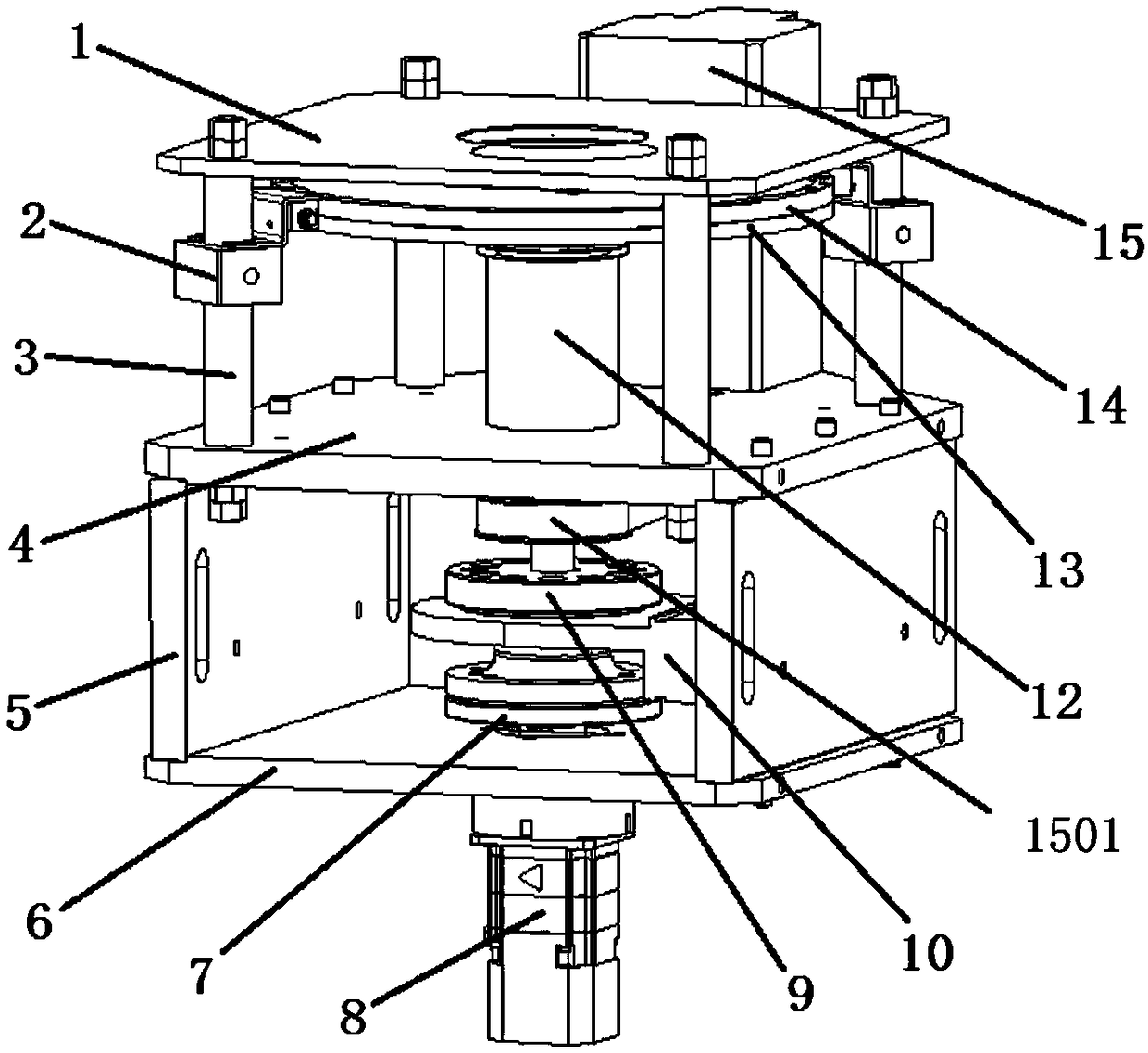

[0021] like figure 1 As shown, the transmission test device based on a circular grating includes a grating assembly, a driving motor 8 , a torque sensor 10 , a shafting 12 and a load assembly 15 arranged on a device holder.

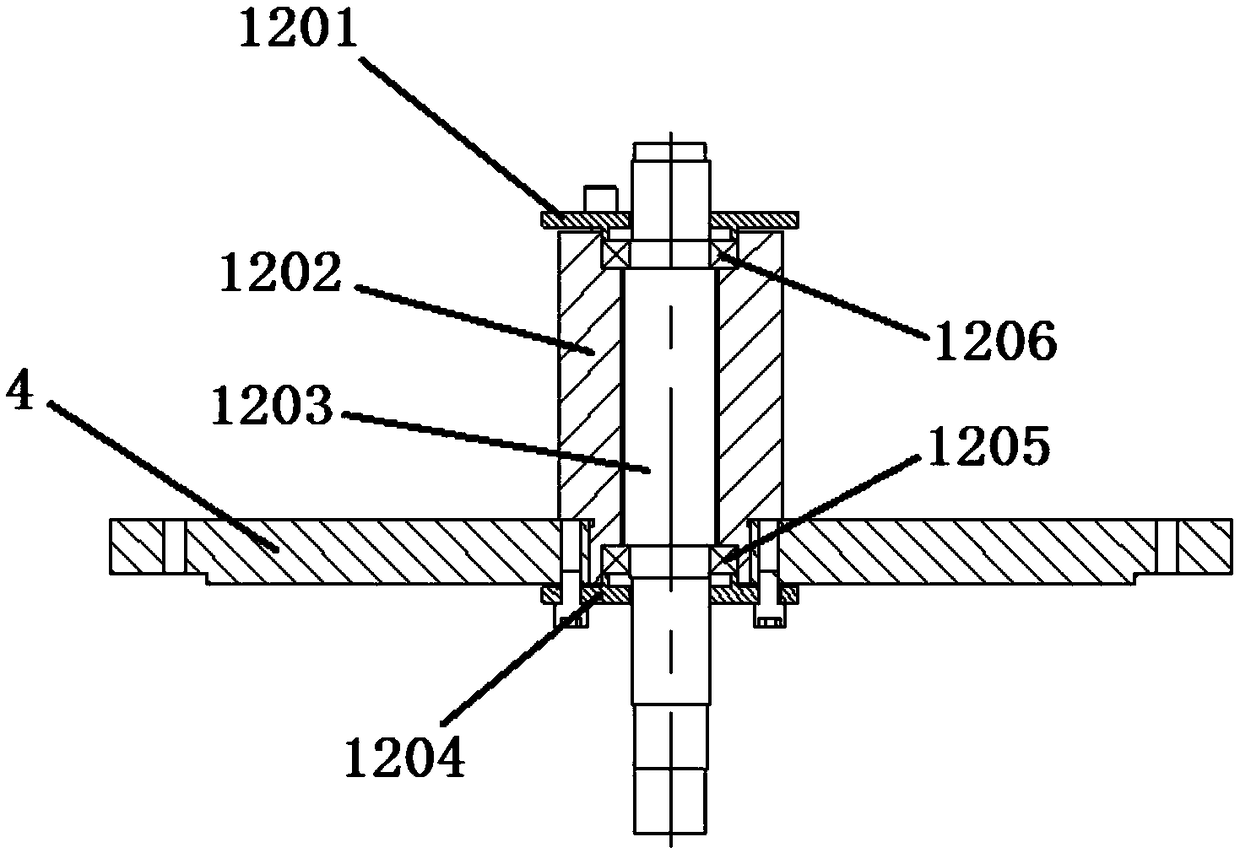

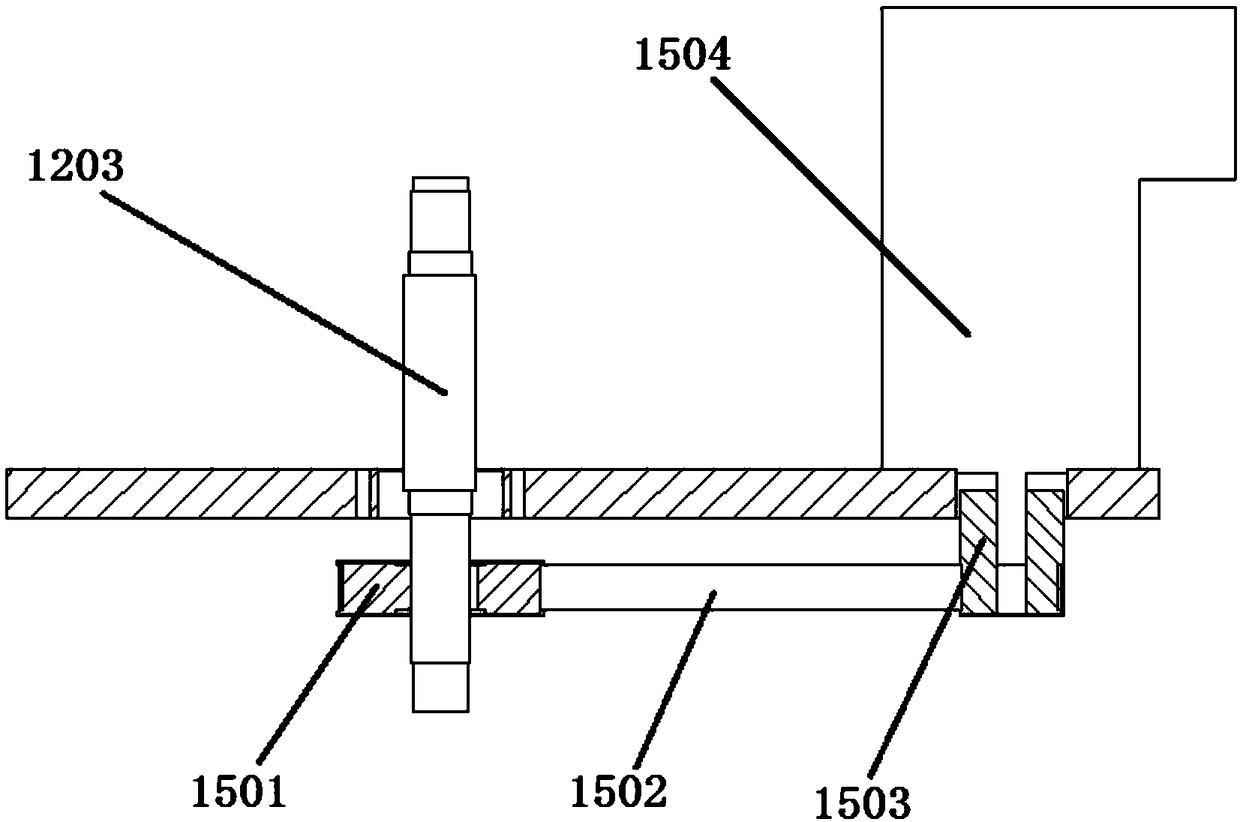

[0022] The device bracket includes a grating guard plate 1, a reference plate 4 and a motor mounting plate 6 arranged horizontally and at intervals from top to bottom. The connecting column 3 is connected and fixed as one; the reference plate 4 and the motor mounting plate 6 are connected and fixed as a whole through two vertical and symmetrically arranged connecting plates 5 at the edge of the board; wherein, the reference plate 4 and the motor mounting plate 6 Mounting holes for installing the drive motor 8 and the shafting 12 are respectively opened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com