Fixed-point automatic oiling device of marine pump shaft seat

A technology for automatic refueling and marine pumps, which is applied to parts, pump components, engine components, etc. of pumping devices for elastic fluids. It can solve the problems of inconvenient operation of lubricating oil stored in the pump shaft seat, and achieve simple structure , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

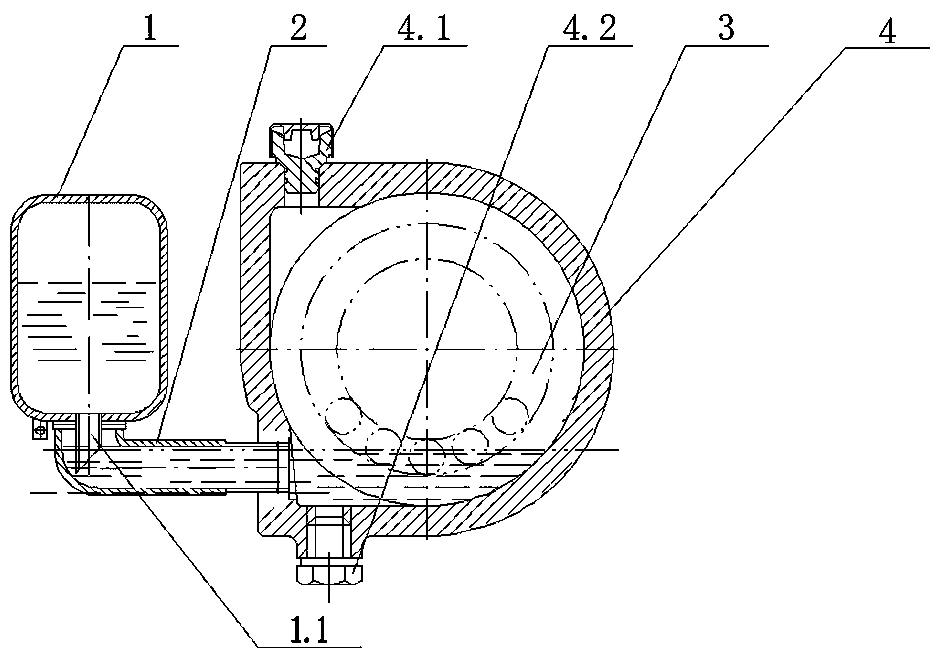

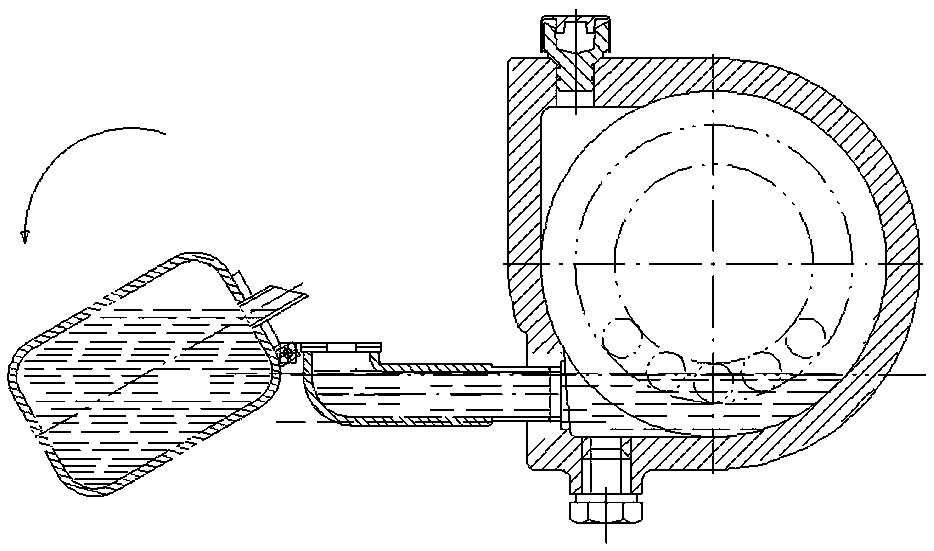

[0016] The fixed-point automatic refueling device for the shaft seat of the marine pump shown in the accompanying drawing includes an oil storage tank 1 , an oil guide pipe 2 , a bearing 3 and a shaft seat shell 4 . The axle seat shell 4 is a shell with a "D" shape in cross section, bearings and lubricating oil are placed in the inner cavity of the shell, the top layer is provided with a venting screw plug 4.1, and the bottom layer is provided with a draining screw plug 4.2. The oil guide pipe 2 is a "L" shaped pipe in a lying position, and the longer end is connected horizontally to the through hole at the bottom of the side of the shaft seat shell 4, and the upper inner hole wall of the horizontal oil guide pipe 2 and the shaft seat shell 4 set the upper limit of the oil level equal height. The short end of the oil guide pipe 2 is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com